Life extension and repair method of a vertical stainless steel bright annealed muffle tube

A stainless steel strip and bright annealing technology, which is applied in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve the problems of high cost, waste of muffle tube materials, and low material utilization rate, and achieve consistent strength from top to bottom, prolong service life, and repair The effect of cycle extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

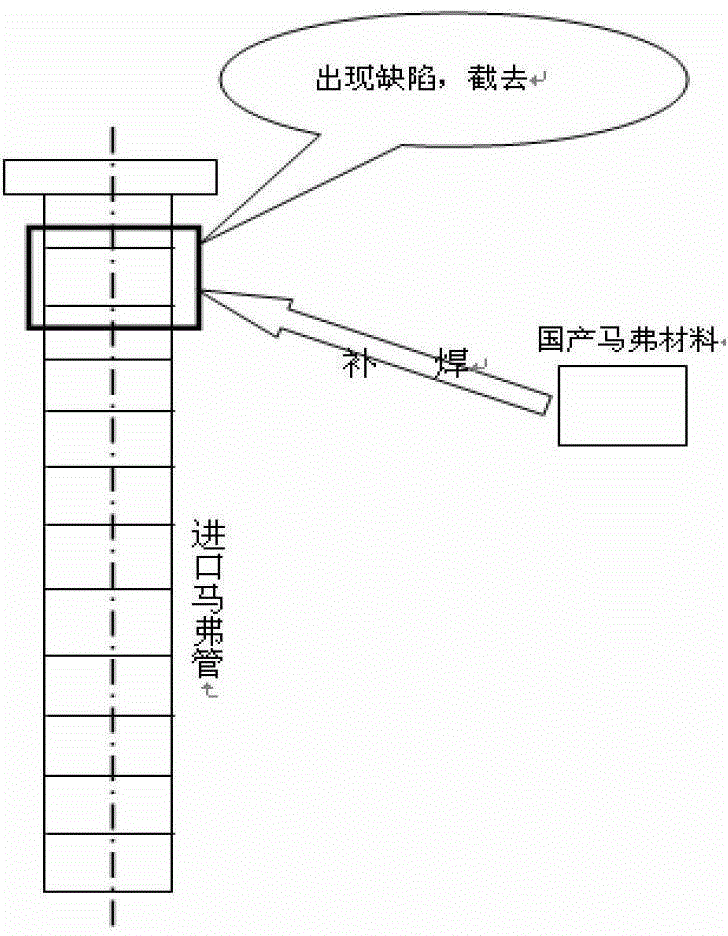

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings. A life extension and repair technology for a vertical stainless steel bright annealed muffle tube, the steps are:

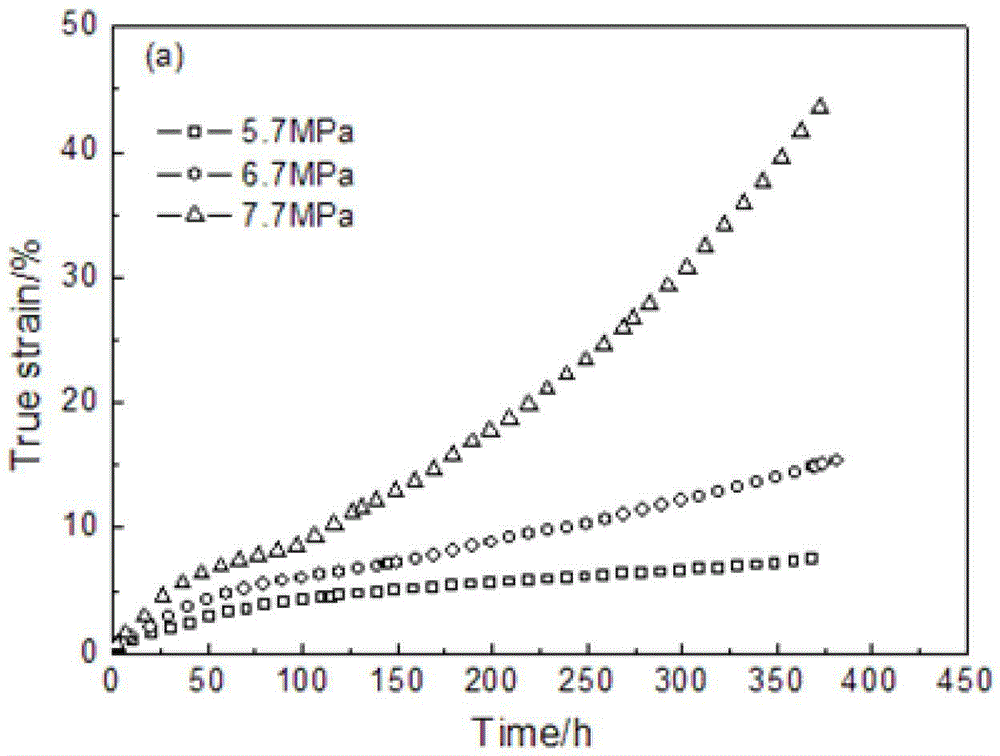

[0024] Step 1: The domestic muffle material to be replaced is BSTMUF601 alloy (a new steel grade jointly developed by Baosteel Special Steel and Baoxin). The main components of the material are shown in Table 1.

[0025] [Table 1]

[0026]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com