430 stainless steel for cold stamping processing, and manufacturing method thereof

A manufacturing method, stainless steel technology, applied in the field of iron and steel materials, can solve the problems of poor formability, poor polishing performance, low cold rolling reduction rate, etc., to improve the formability of finished products, ensure cold stamping formability, and ensure elongation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

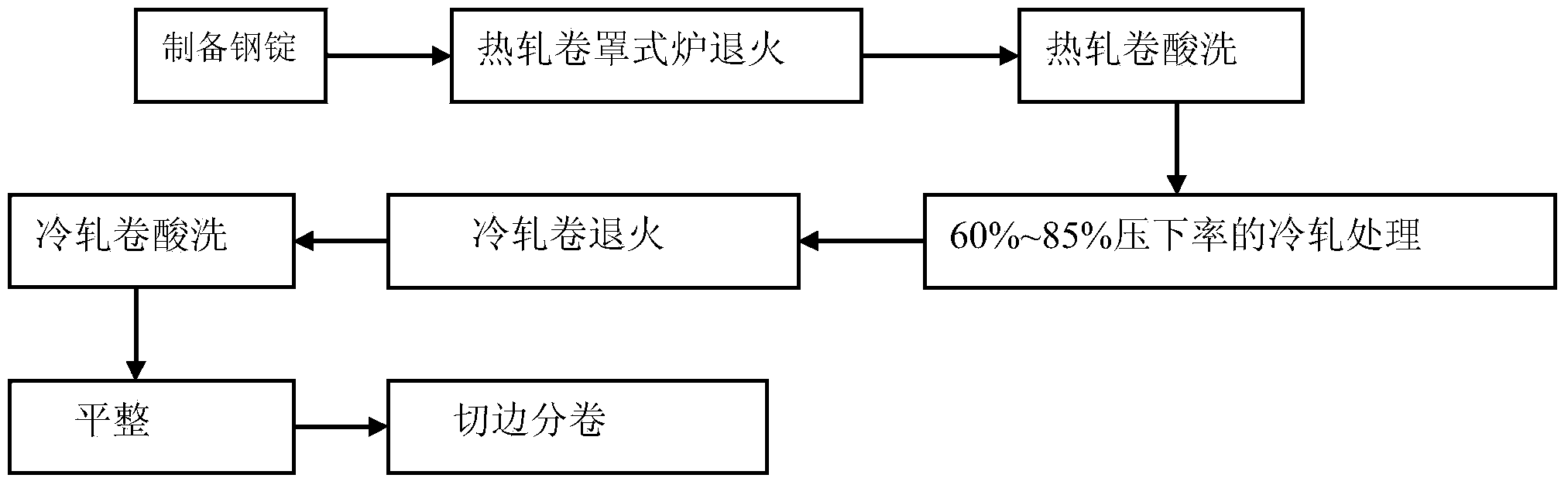

Method used

Image

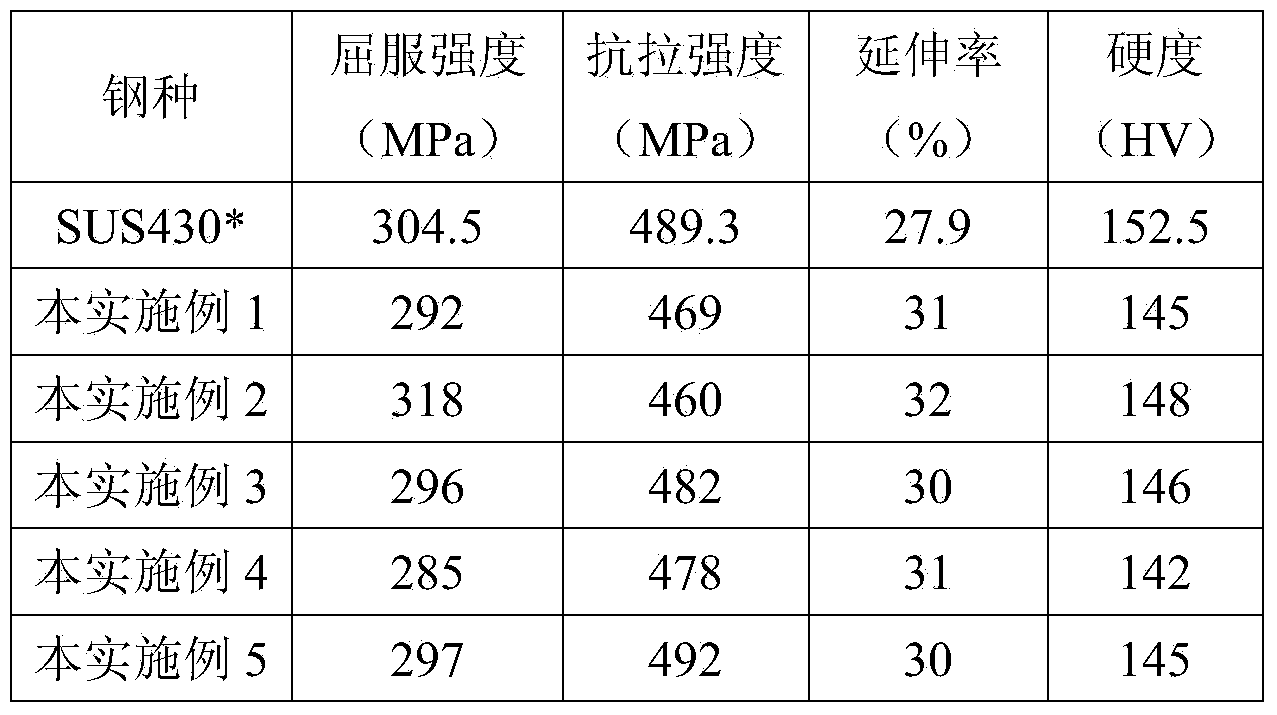

Examples

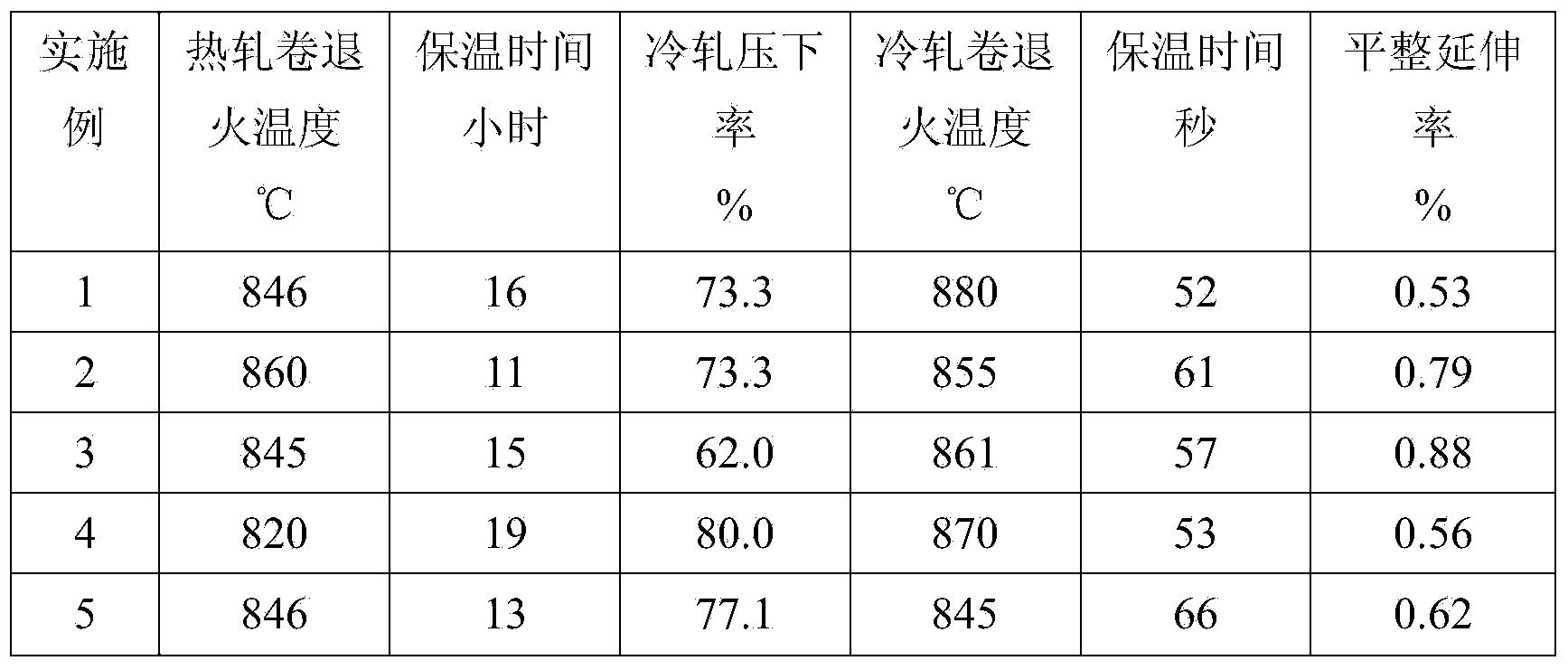

Embodiment 1

[0034] 1. A kind of 430 stainless steel suitable for cold stamping processing, the weight percentage ratio of its chemical composition is:

[0035] C: 0.048%, Si: 0.32%, Mn: 0.38%, P: 0.025%, S: 0.005%, Cr: 16.18%, Ni: 0.21%, N: 0.036%, the balance is iron and unavoidable trace impurities .

[0036] 2, the manufacturing method of this 430 stainless steel comprises the following steps:

[0037] (1) Prepare steel ingot or slab according to the proportioning;

[0038] (2) Annealing in bell furnace for hot-rolled coils, the temperature is controlled at 846°C, and the holding time is 15 hours;

[0039] (3) pickling of hot-rolled coils to remove iron oxide scales produced by hot-rolling and bell-type furnace annealing;

[0040] (4) Cold rolling, the reduction rate is controlled between 73.3%;

[0041] (5) Annealing of cold-rolled coils, the temperature is controlled between 870°C and the holding time is between 52s;

[0042] (6) pickling of cold-rolled coils to remove iron oxid...

Embodiment 2

[0046] 1. A kind of 430 stainless steel suitable for cold stamping processing, the weight percentage ratio of its chemical composition is:

[0047] C: 0.049%, Si: 0.23%, Mn: 0.35%, P: 0.029%, S: 0.001%, Cr: 16.40%, Ni: 0.09%, N: 0.039%, the balance is iron and unavoidable trace impurities .

[0048] 2, the manufacturing method of this 430 stainless steel comprises the following steps:

[0049] (1) Prepare steel ingot or slab according to the proportioning;

[0050] (2) Annealing in a bell-type furnace for hot-rolled coils, the temperature is controlled at 847°C, and the holding time is 15 hours;

[0051] (3) pickling of hot-rolled coils to remove iron oxide scales produced by hot-rolling and bell-type furnace annealing;

[0052] (4) Cold rolling, the reduction rate is controlled between 77.1%;

[0053] (5) Annealing of cold-rolled coils, the temperature is controlled between 872°C and the holding time is between 51s;

[0054] (6) pickling of cold-rolled coils to remove ir...

Embodiment 3

[0058] 1. A kind of 430 stainless steel suitable for cold stamping processing, the weight percentage ratio of its chemical composition is:

[0059] C: 0.053%, Si: 0.24%, Mn: 0.26%, P: 0.027%, S: 0.004%, Cr: 16.13%, Ni: 0.13%, N: 0.034%, the balance is iron and unavoidable trace impurities .

[0060] 2, the manufacturing method of this 430 stainless steel comprises the following steps:

[0061] (1) Prepare steel ingot or slab according to the proportioning;

[0062] (2) Annealing in the hot-rolled coil bell furnace, the temperature is controlled at 845 ° C, and the holding time is 15 hours;

[0063] (3) pickling of hot-rolled coils to remove iron oxide scales produced by hot-rolling and bell-type furnace annealing;

[0064] (4) Cold rolling, the reduction rate is controlled between 73.3%;

[0065] (5) Annealing of cold-rolled coils, the temperature is controlled between 871°C and the holding time is between 53s;

[0066] (6) pickling of cold-rolled coils to remove iron oxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com