Composite corrosion inhibitor resisting to corrosion CO2/H2S/HCl corrosion

A composite corrosion inhibitor and corrosion inhibitor technology, applied in the field of corrosion inhibitor and composite corrosion inhibitor, can solve the problems of affecting the adsorption effect, unable to achieve the inhibitory effect, large steric hindrance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

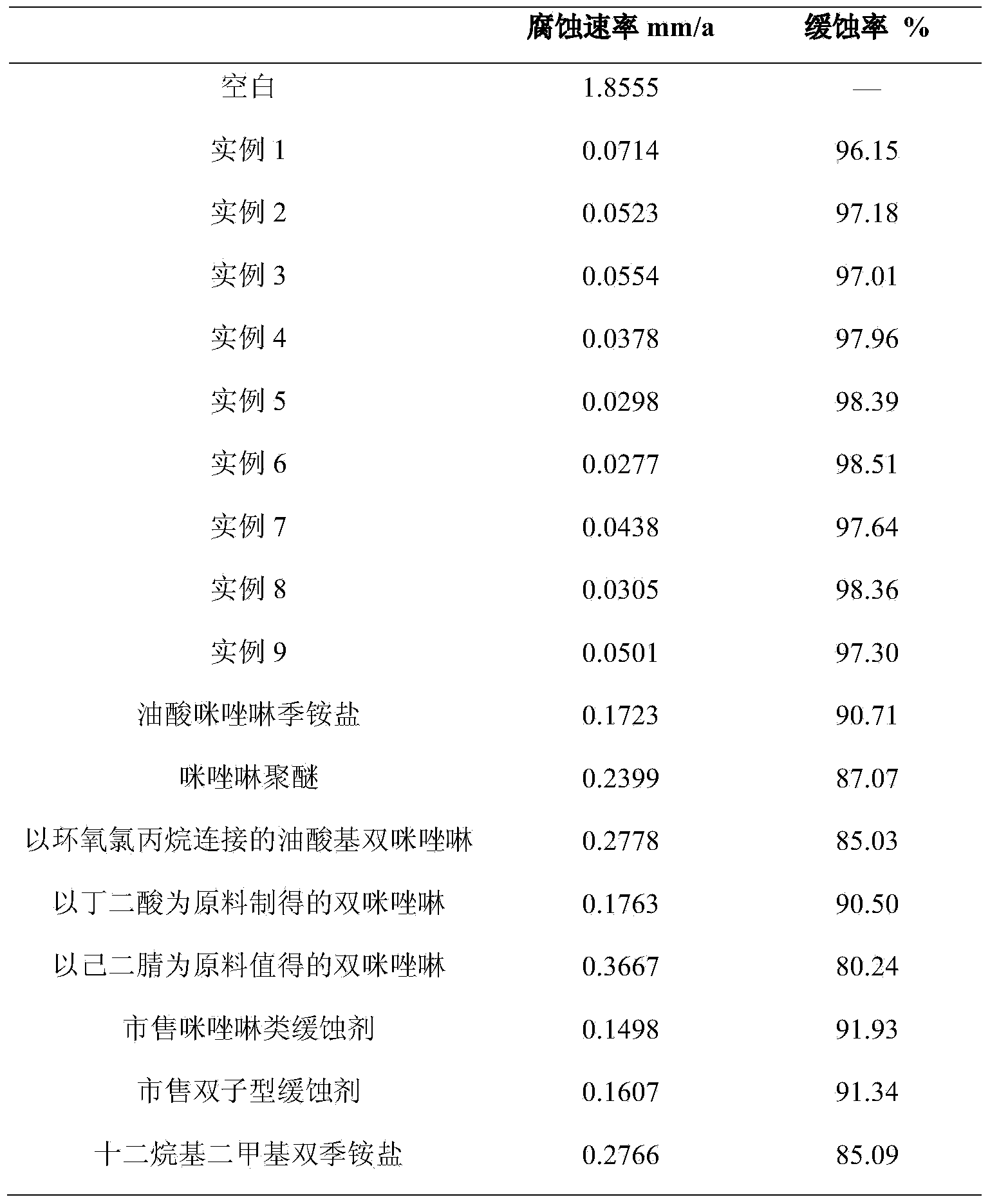

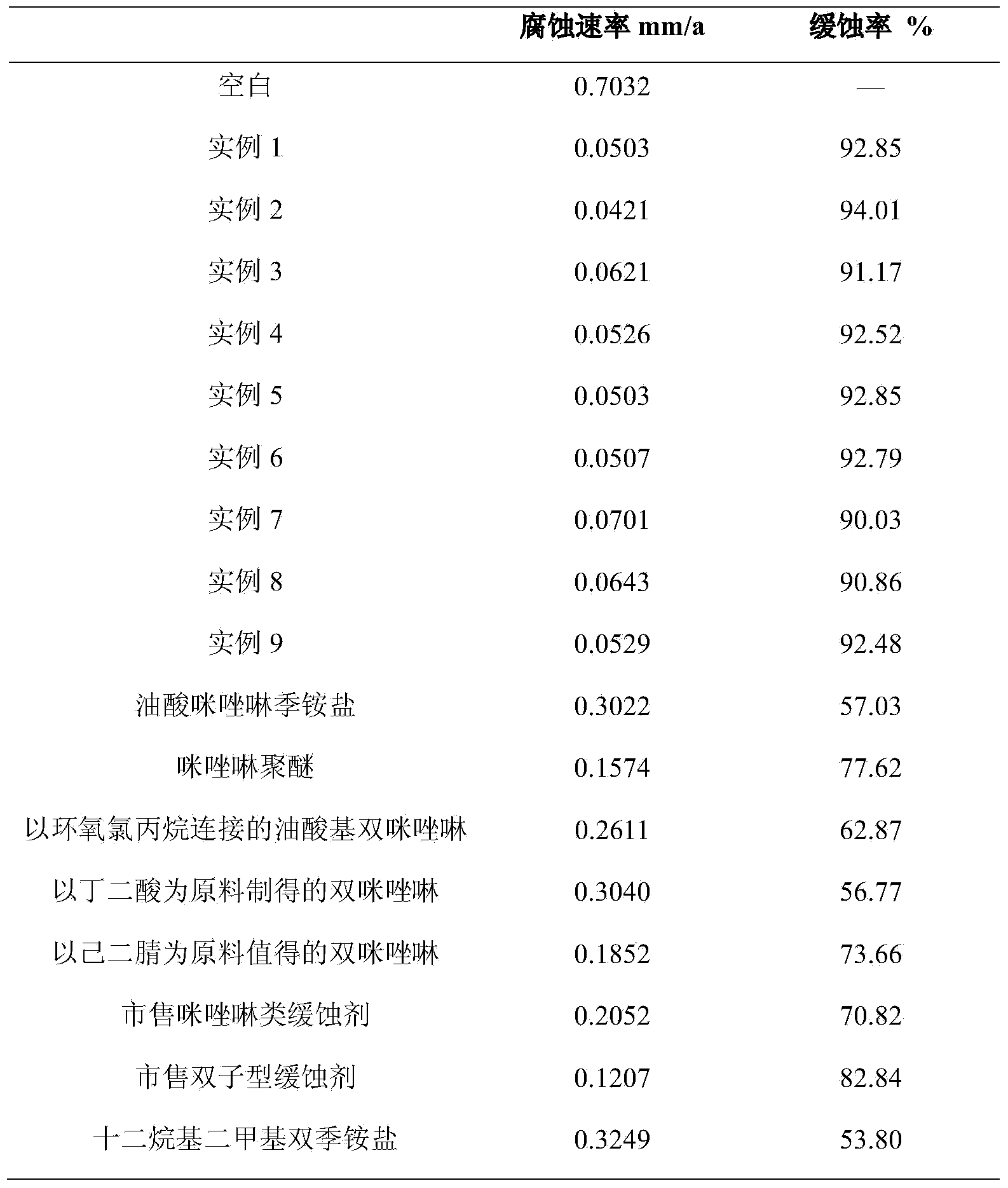

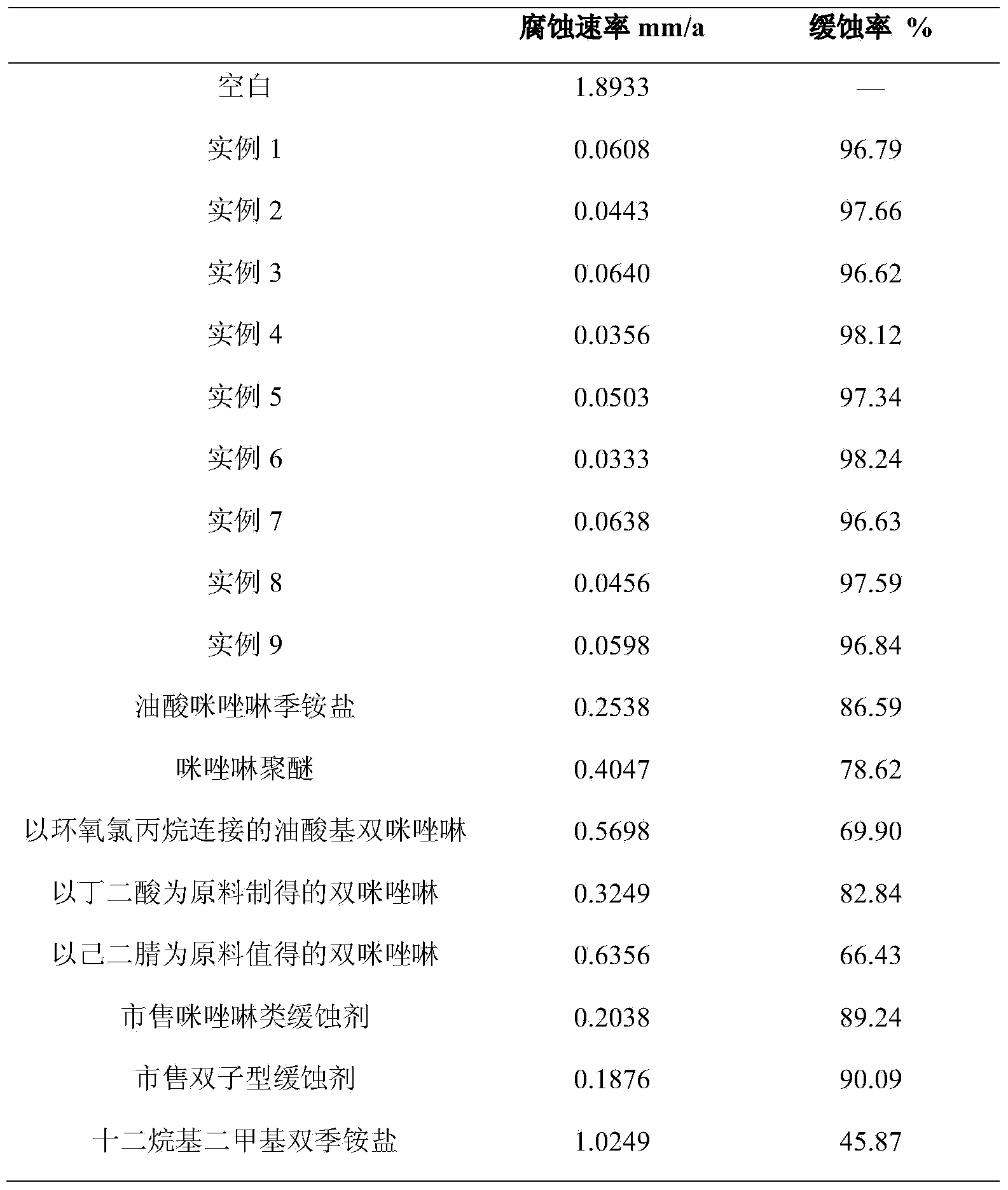

Examples

Embodiment 1

[0016] ① Dissolve 6g of thiourea in 34g of isoamyl alcohol, then mix 40g of heptadecyl imidazoline with 0.13g of H 3 BO 3 After mixing and raising the temperature to 100°C, start to add the isoamyl alcohol solution of thiourea dropwise, and control the temperature at 100°C to 130°C, finish the dropwise addition in 2 to 3 hours, and then react at 105°C to 130°C for 9 hours;

[0017] ② Mix 15g of triethylenetetramine, 6g of thiourea and 21g of n-butanol, stir and heat up, and react at 105°C to 120°C for 8 hours;

[0018] ③Mix the reaction products of steps ① and ② at a ratio of 4:1 to obtain the corrosion inhibitor.

Embodiment 2

[0020] ①Dissolve 5g of thiourea in 35g of benzyl alcohol, then mix 40g of 9-heptadecenyl imidazoline with 0.12g of H 3 BO 3 After mixing and raising the temperature to 100°C, start to add the benzyl alcohol solution of thiourea dropwise, and control the temperature at 100°C to 130°C for 2 to 3 hours, then react at 140°C to 160°C for 5 hours;

[0021] ② Mix 20g of tetraethylenepentamine, 6g of thiourea and 26g of benzyl alcohol, stir and heat up, and react at 140°C to 160°C for 6 hours;

[0022] ③Mix the reaction products of steps ① and ② at a mass ratio of 1:1 to obtain a corrosion inhibitor.

Embodiment 3

[0024] ①Dissolve 5g of thiourea in 35g of n-butanol, then mix 40g of 9,12-heptadecadienyl imidazoline with 0.15g of H 3 BO 3 After mixing and raising the temperature to 100°C, start to add the n-butanol solution of thiourea dropwise, and control the temperature at 100°C to 115°C, finish the dropwise addition in 2 to 3 hours, and then continue the reaction at 100°C to 115°C for 10 hours;

[0025] ② Mix 25g of pentaethylenehexamine, 5g of thiourea and 30g of isoamyl alcohol, stir and heat up, and react at 100°C to 115°C for 10 hours;

[0026] ③Mix the reaction products of steps ① and ② at a mass ratio of 5:1 to obtain a corrosion inhibitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com