Doffing process used for ring-spinning doffer

A technology of doffing machine and ring spinning, which is applied in the direction of textiles and papermaking, which can solve the problems of delaying production efficiency, increasing labor costs, and prone to broken ends, and achieve continuous production, reduce labor, improve production efficiency and yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The doffing process that the present invention is used for ring spinning doffer comprises:

[0021] Step 1: pull out the full yarn bobbin 5 from the spindle bar 6 through the tube pulling device 2 on the doffing machine 1, and at this time, the yarn 8 between the spindle bar 6 and the full yarn bobbin 5 is in a connected state,

[0022] Step 2: place the empty bobbin 7 on the spindle bar 6 of the spinning frame 9 through the tube insertion device 3 on the doffing frame 1, at this time, the connected yarn 8 between the full bobbin 5 and the spindle bar 6 is pressed ,

[0023] Step 3: Disconnect the yarn 8 connected between the spindle bar and the full bobbin 5 through the yarn breaking device 4 on the doffing machine 1,

[0024] Step 4: place the full bobbin 5 in the doffer 1 through the tube pulling device 2 on the doffer 1,

[0025] Step 5: Repeat the above actions.

[0026] The above method can be applied to any automatic doffing machine with extubation device, int...

Embodiment 2

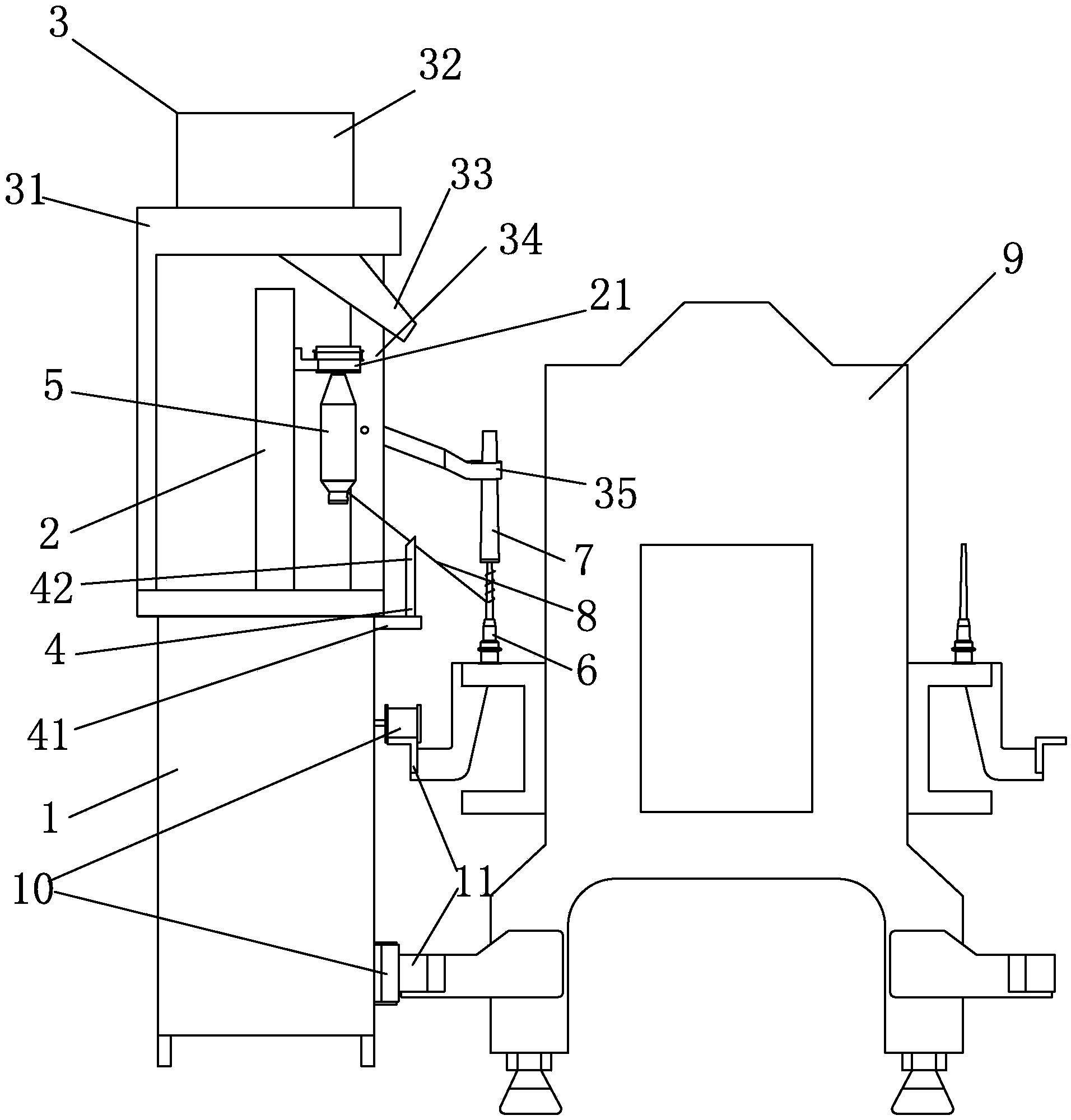

[0028] Such as figure 1 As shown, the automatic doffing machine that uses the steps of the above method includes a tube pulling device 2, a tube insertion device 3 and a yarn breaking device 4, and the tube pulling device 2 is a Cartesian robot, and the structure and work of the Cartesian robot For the process, refer to the invention of an automatic control device for a doffing machine in my country, the publication number is 102634891A, the Cartesian coordinate robot is arranged above the doffer 1, and several extruding manipulators 21 are arranged on the Cartesian coordinate robot. An intubation device 3 is provided above the Cartesian robot, and a yarn breaking device 4 is provided below the Cartesian robot near the side of the spinning frame 9 . The intubation device 3 includes a support 31, an empty bobbin box 32, a bobbin channel 33, a profiling column 34 and several intubation manipulators 35, and the support 31 is fixedly welded on the bed body of the doffing machine 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com