A comb-type hyperdispersant, preparation method and application

A hyperdispersant and comb-type technology, which is applied in the field of new materials and chemical industry, can solve the problems of inability to form steric hindrance and poor dispersion effect, and achieve the effects of controllable structure, difficult release and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

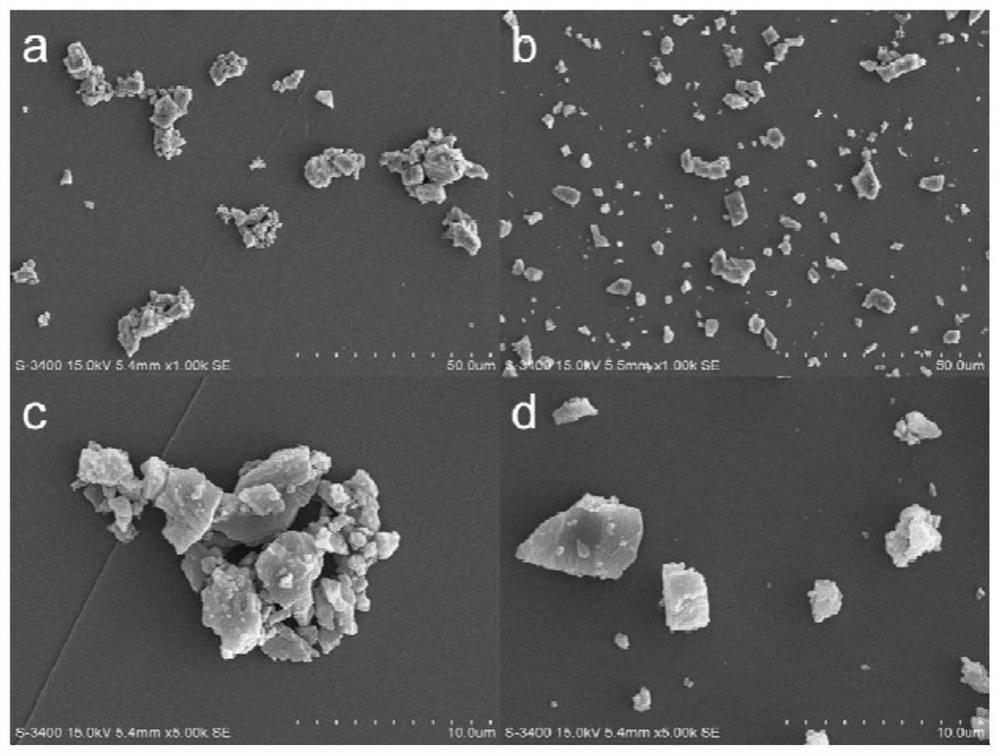

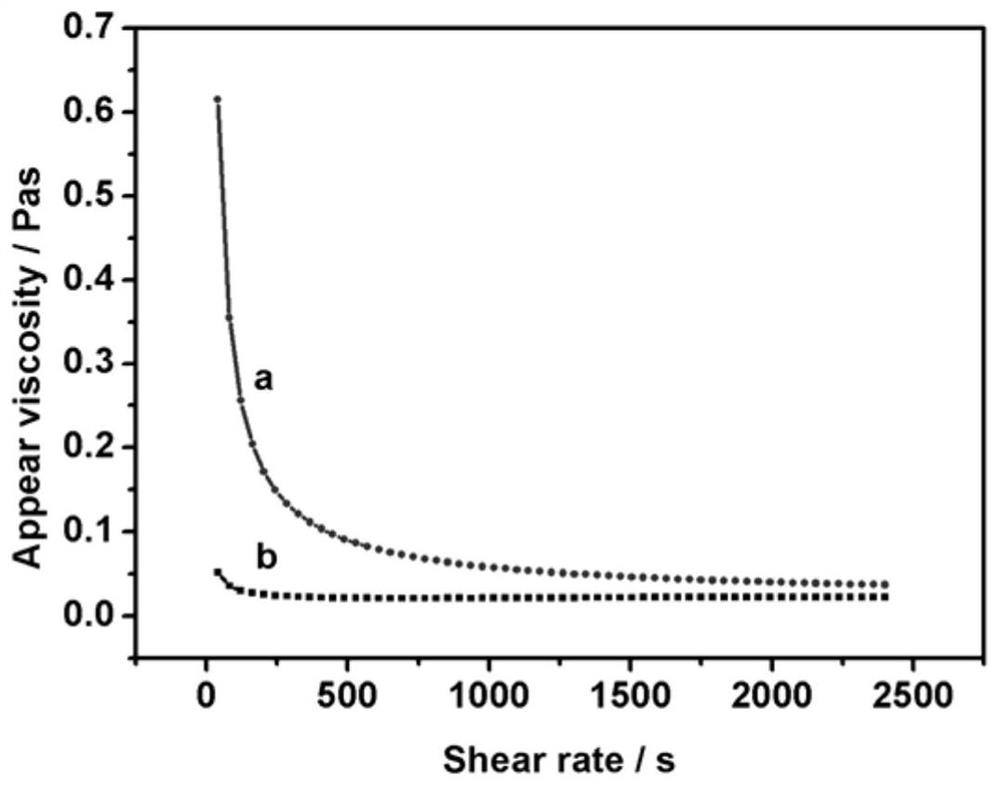

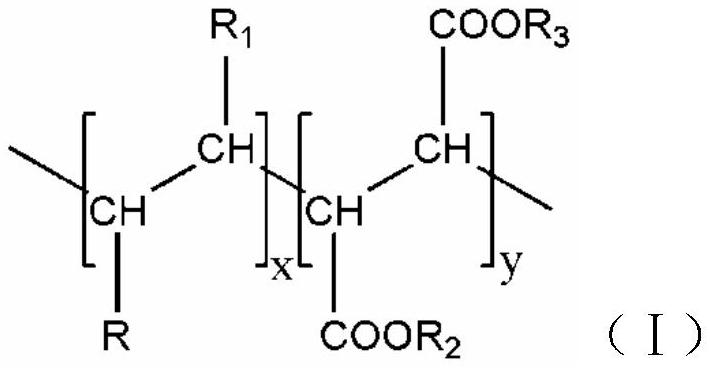

Embodiment 1

[0032] Weigh 72g of caprolactone and 5g of n-octanol into a three-necked flask, add 0.5% catalyst stannous octoate after vacuuming for 2 hours, heat up to 130°C, react under vacuum for 12 hours and cool the product to room temperature to obtain a white The solid is the solvated chain. Weigh 32g of solvated chain, 4g of styrene maleic anhydride and dissolve it in 84g of dioxane. After the raw materials are completely dissolved, add 1.44g of catalyst p-toluenesulfonic acid, control the reaction temperature to 100°C, and remove the solvent after 8h of reaction, namely The hyperdispersant product H1 was obtained. R is hydrogen in this embodiment, R 1 is phenyl, R 2 , R 3 It is hydrogen or polyester, the molecular weight of polyester is about 2000, the ratio of hydrogen to polyester is 3:2, x=10, y=10.

Embodiment 2

[0034] Weigh 72g of caprolactone and 5g of n-octanol into a three-necked flask, add 0.5% catalyst stannous octoate after vacuuming for 2 hours, heat up to 130°C, react under vacuum for 12 hours and cool the product to room temperature to obtain a white The solid is the solvated chain. Weigh 8g of solvated chain, 4g of styrene maleic anhydride and dissolve in 28g of dioxane. After the raw materials are completely dissolved, add 0.48g of catalyst p-toluenesulfonic acid, control the reaction temperature to 100°C, and remove the solvent after 8h of reaction, namely The hyperdispersant product H2 is obtained. R is hydrogen in this embodiment, R 1 is phenyl, R 2 , R 3 It is hydrogen or polyester, the molecular weight of polyester is about 2000, the ratio of hydrogen to polyester is 9:1, x=10, y=10.

Embodiment 3

[0036] Weigh 110g of caprolactone and 5g of n-octanol into a three-necked flask, add 0.5% catalyst stannous octoate after evacuating for 2 hours, heat up to 130°C, react under vacuum for 12 hours, and cool the product to room temperature to obtain a white The solid is the solvated chain. Weigh 60g of solvated chain, 4g of styrene maleic anhydride and dissolve in 150g of dioxane, add 2.56g of catalyst p-toluenesulfonic acid after the raw materials are completely dissolved, control the reaction temperature to 100°C, and remove the solvent after 8h of reaction, namely The hyperdispersant product H3 was obtained. In this embodiment R is hydrogen, R 1 is phenyl, R 2 , R 3 It is hydrogen or polyester, the molecular weight of polyester is about 3000, the ratio of hydrogen to polyester is 1:1, x=10, y=10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com