Ultra-large plastic circular loom

A super-large circular loom technology, applied to circular looms, looms, textiles, etc., can solve problems affecting product quality, small driving power, uneven warp tension distribution, etc., to improve and reduce warp tension unevenness Less possibility of slippage, effect of reducing unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

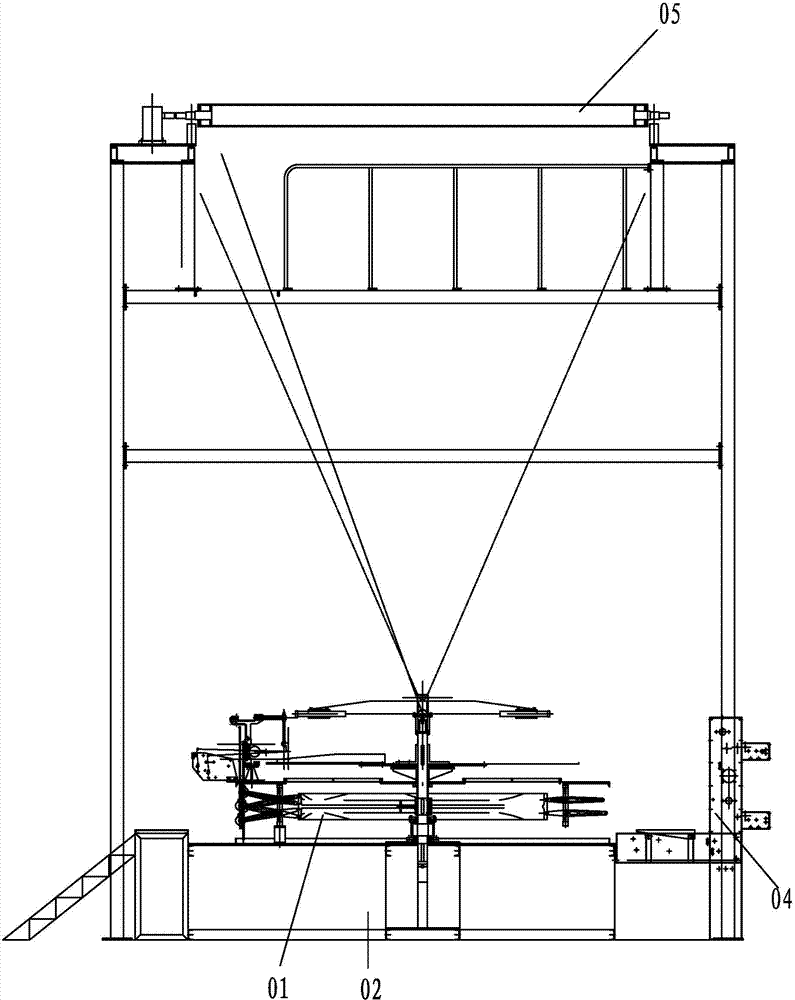

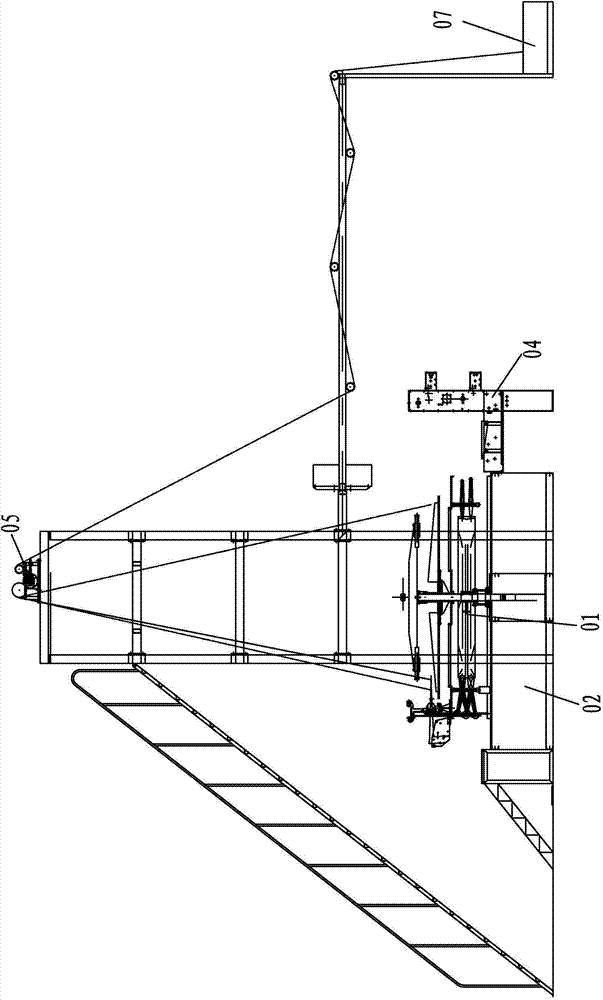

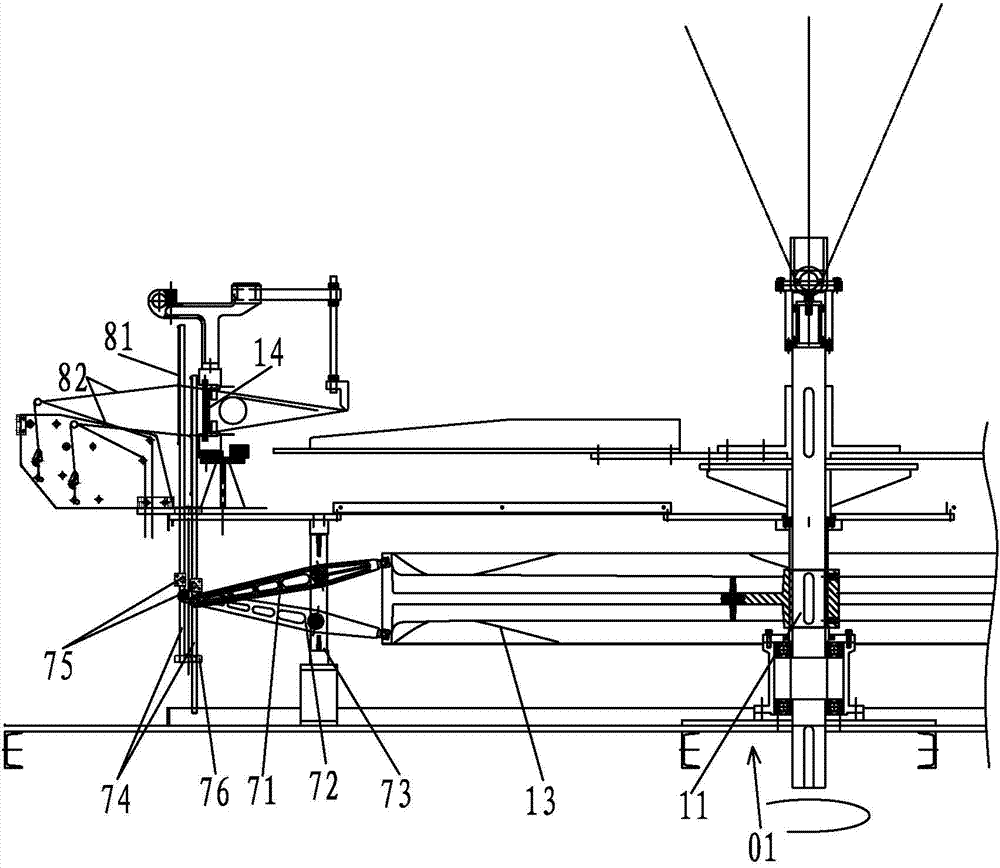

[0028] like Figure 1a , 1b , shown in 1c, the super-large plastic circular loom of the present invention comprises a main frame 01, a let-off device 04, a cloth lifting device 05, and a cloth rolling device 07, such as figure 2 As shown, the warp frame 03 is arranged on the periphery of the main frame 01, the warp let-off device 04 is arranged between the main frame 01 and the warp frame 03, the main frame 01 is arranged on the table body 02, the main frame 01 includes a driving device and a main shaft 11 connected to the driving device, The driving device includes a motor and a reducer, the host 01 is provided with a shuttle 14, and the main shaft 11 is connected with a cam 13, such as image 3 As shown, the outer cylindrical surface of the cam 13 is provided with two circumferentially extending annular grooves 131, 133, as Figure 4 As shown, the expanded shapes of the two annular grooves 131, 133 are both sinusoidal curves with seven cycles and the phase difference betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com