Soil material with high unconfined compressive strength

A technology of compressive strength and soil materials, applied in the directions of organic fertilizers, soil conditioning materials, fertilizer mixtures, etc., can solve the problems of unclear effect of modification effect of soil sample water content nanomaterials content, unclear reinforcement mechanism, etc. Achieve the effect of increasing unconfined compressive strength and improving engineering properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

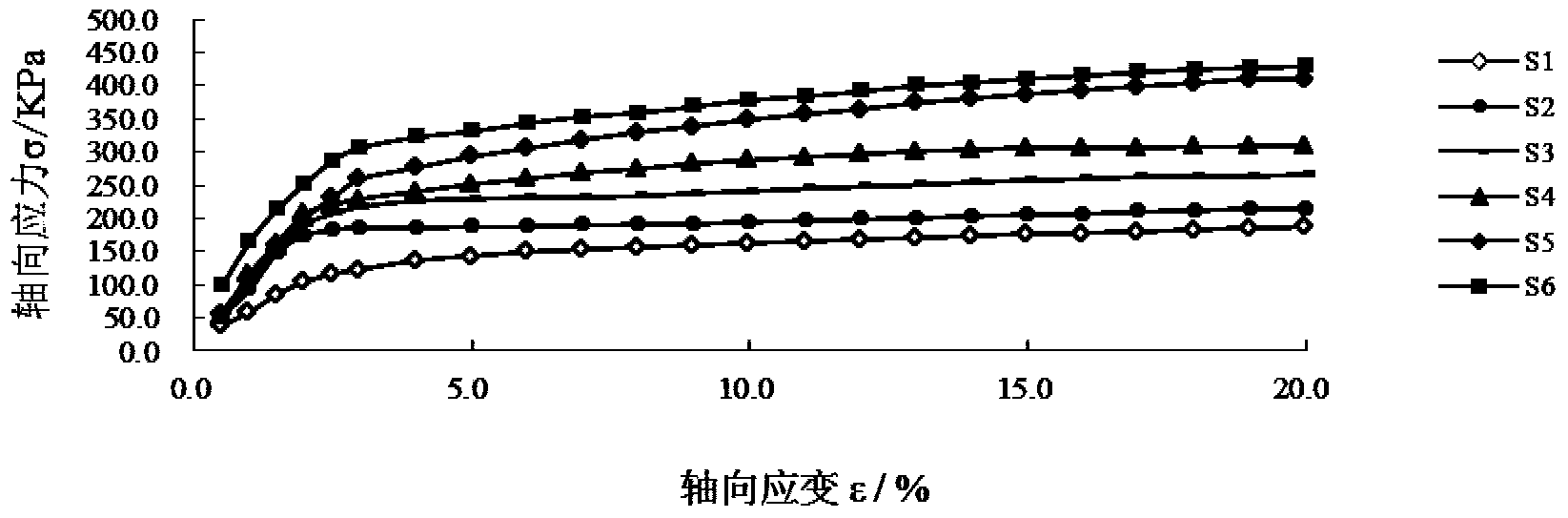

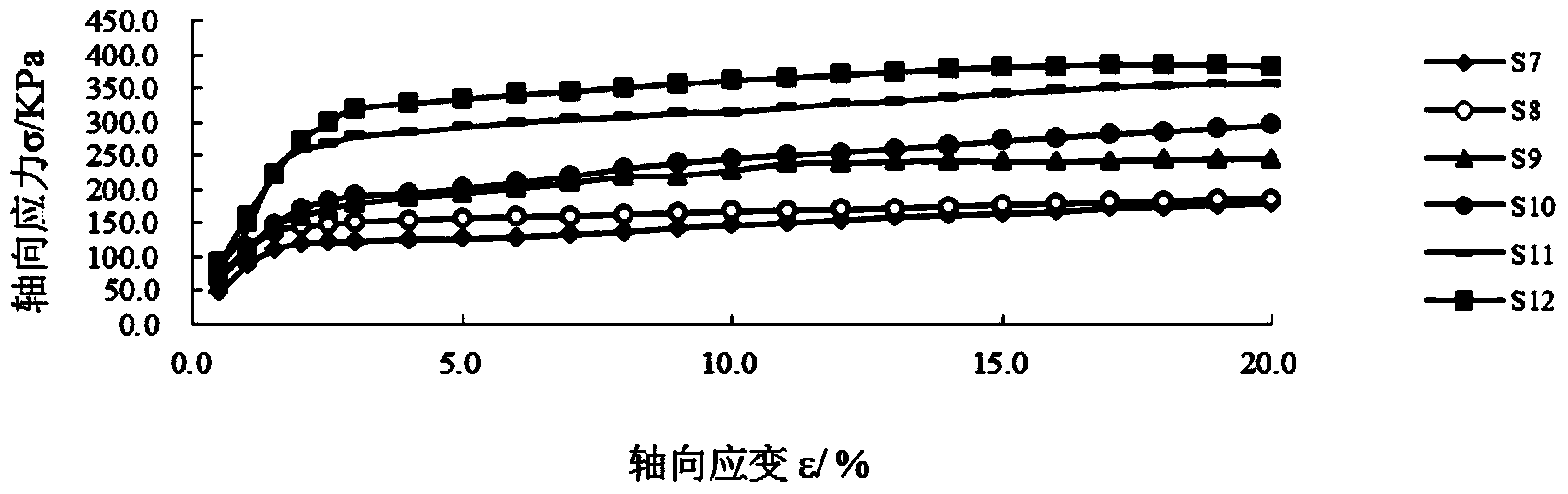

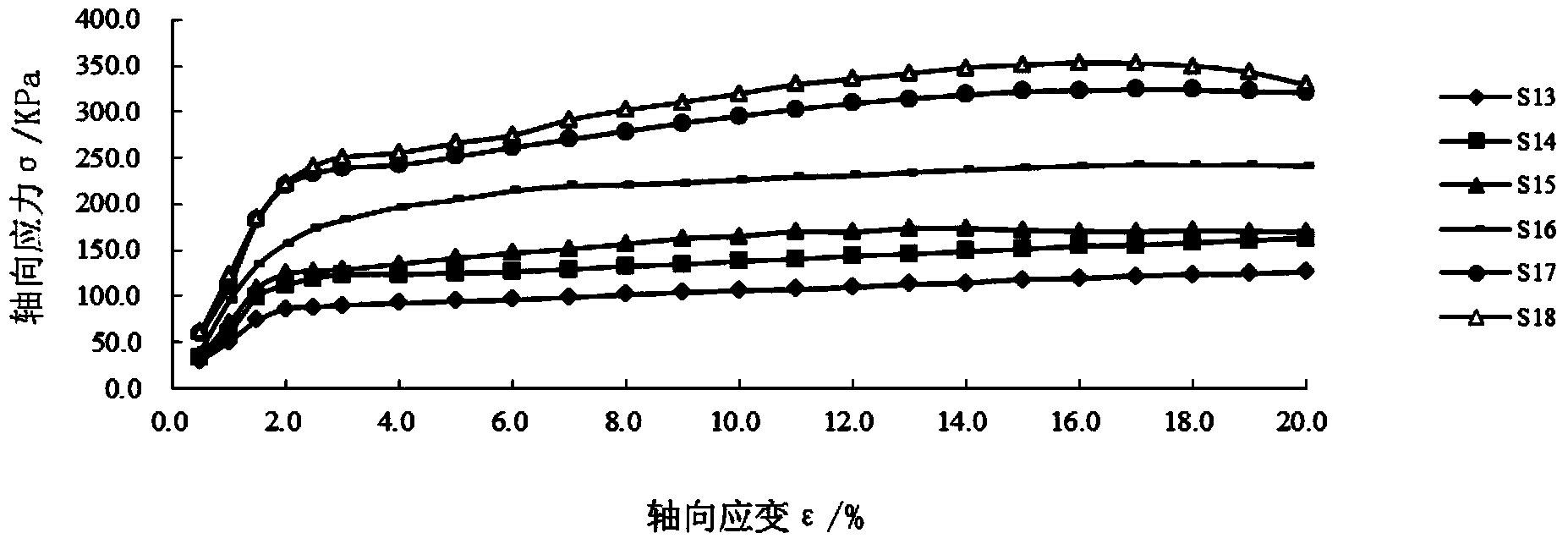

Image

Examples

Embodiment 1

[0042] Mixed soil preparation, take the preparation of 150g mixed soil material as an example. The preparation steps of mixed soil material are as follows: (1) the quality of dry soil is 144g, and the quality that takes by weighing required NA is 6g in the ratio of 4% by NA dosage; The optimal water content obtained in the light compaction test in the Regulations is 16%. Add 150gx0.16=24g of water to the mixed soil, mix well to prevent the formation of lumps, and leave it in a humidifier for 24 hours to obtain NA Modified soil mix.

[0043] The test procedure for the prepared mixed soil is as follows:

[0044] The first step is to prepare a cylindrical test sample by pressing the sample. The sample is 80mm high and the cross-sectional diameter is 39.1mm. After the sample is formed, it is sealed with a plastic film and placed in a normal temperature curing box ((20±1)°C, ( 96±2)% relative humidity) curing for 7 days;

[0045] In the second step, put the sample into the satur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com