Construction process of pressing-and-embedding special-shaped cast-in-place pile and equipment thereof

A construction technique and cast-in-place pile technology, which is applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of high construction cost and large amount of concrete, achieve fast construction, increase pile end resistance, and increase horizontal bearing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] A construction technology for pressure-embedded special-shaped cast-in-situ piles, comprising the following steps:

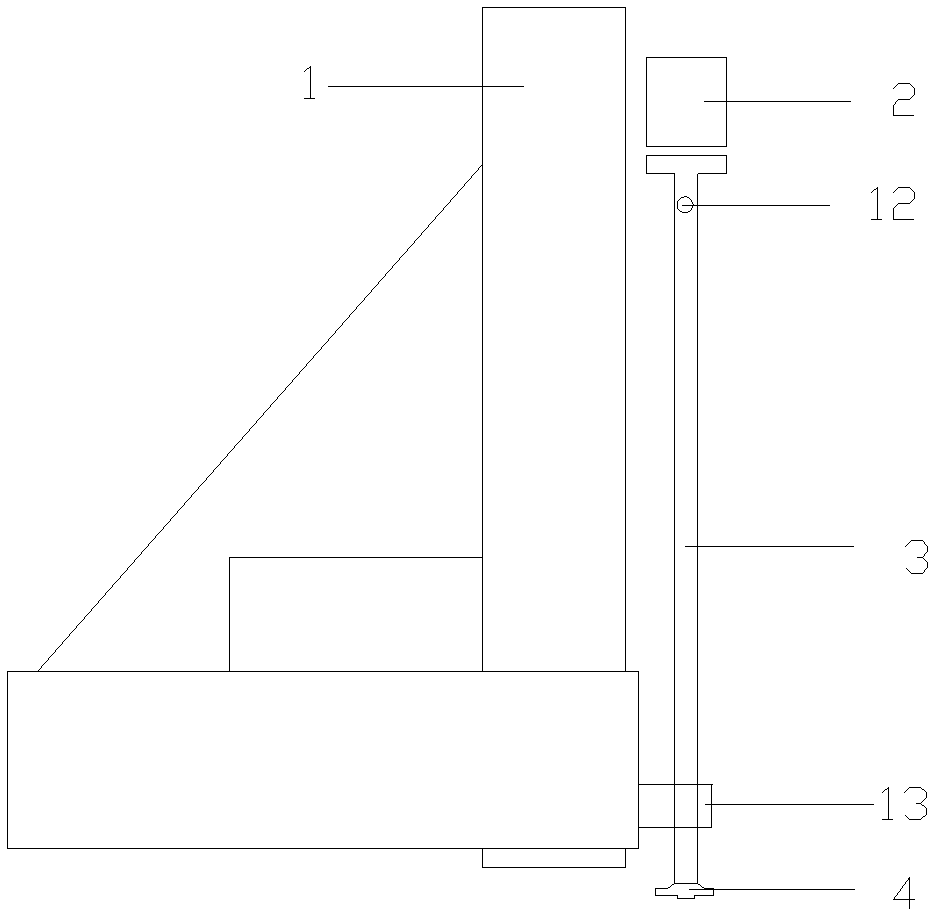

[0061] 1) First, the pile driver 1 is in place, and the vibratory hammer 2, the hole-forming guide rod 3 and the pile head 4 are installed;

[0062] 2) Use the vibrating hammer 2 to move up and down to press the pile head 4 into the soil layer, and pour concrete during the pressing process, so that the concrete top surface continues to maintain the preset elevation according to the construction requirements;

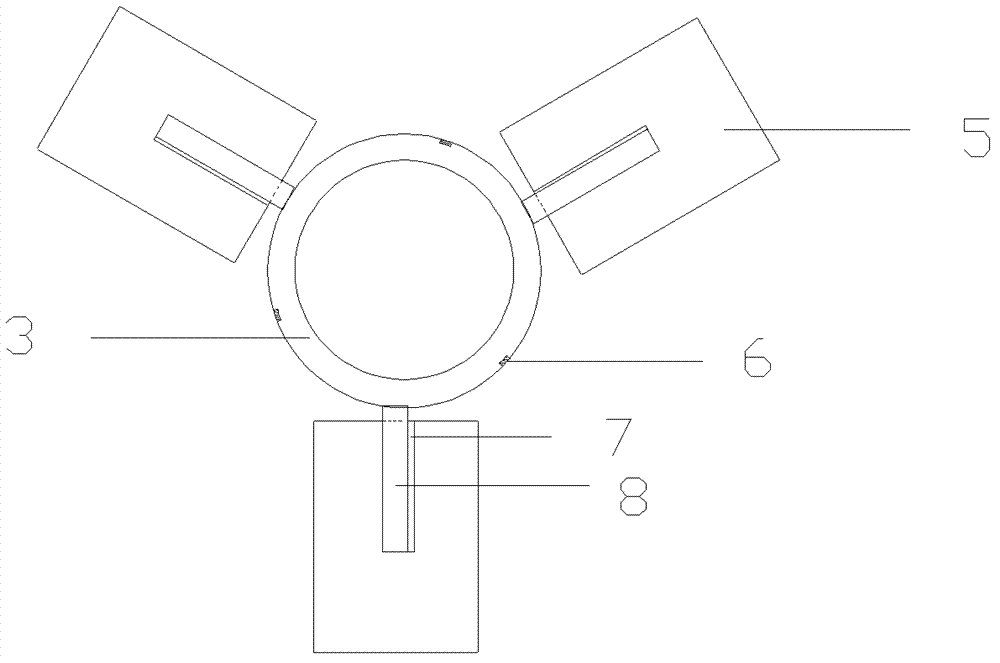

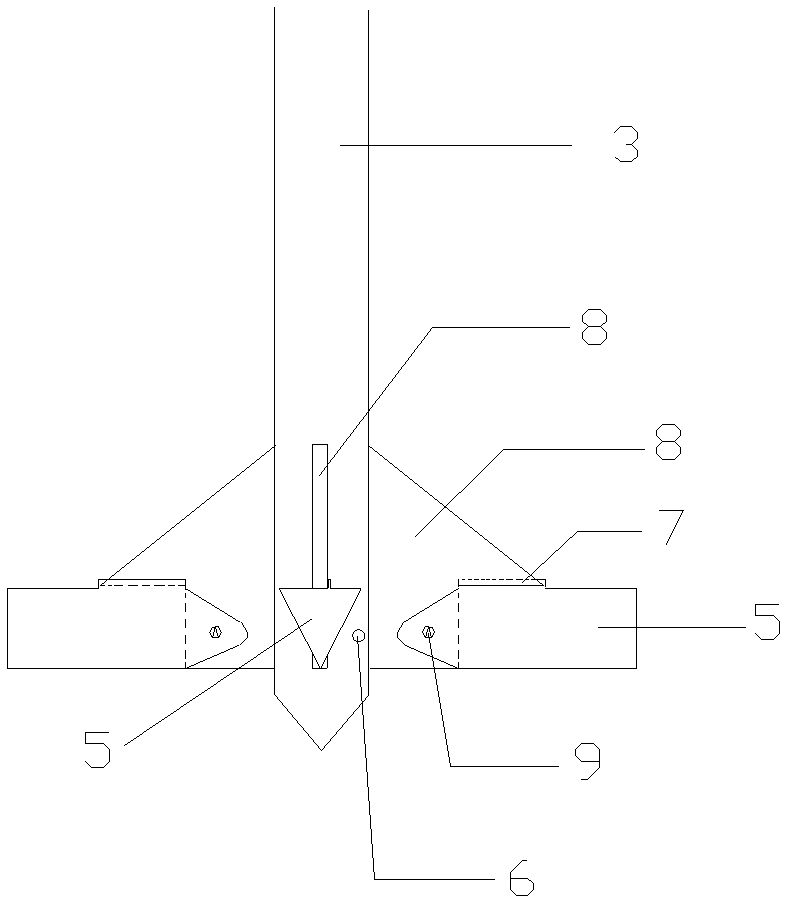

[0063] 3) When the pile head 4 reaches the preset depth required by the construction, open the torsion pump box 13, rotate the hole-forming guide rod 3 and the pile head 4, and make them rotate at a constant speed of 120 degrees; The high-pressure grouting port 12 injects the grout, and the grout is ejected from the grouting port 6 at the bottom of the hole-forming guide rod 3 to form a conical enlarged head at the bottom of the pile;

[0064] 4) A...

Embodiment 2

[0073] A construction technology for pressure-embedded special-shaped cast-in-situ piles, comprising the following steps:

[0074] 1) First, the pile driver 1 is in place, and the vibratory hammer 2, the hole-forming guide rod 3 and the pile head 4 are installed;

[0075] 2) Use the vibrating hammer 2 to move up and down to press the pile head 4 into the soil layer, and pour concrete during the pressing process, so that the concrete top surface continues to maintain the preset elevation according to the construction requirements;

[0076] 3) When the pile head 4 reaches the preset depth required by the construction, open the torsion pump box 13, rotate the hole-forming guide rod 3 and the pile head 4, and make them rotate at a constant speed of 120 degrees; The high-pressure grouting port 12 injects the grout, and the grout is ejected from the grouting port 6 at the bottom of the hole-forming guide rod 3 to form a conical enlarged head at the bottom of the pile;

[0077] 4) A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com