Valve timing control apparatus

A control device, valve timing technology, applied in the direction of valve devices, engine components, machines/engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

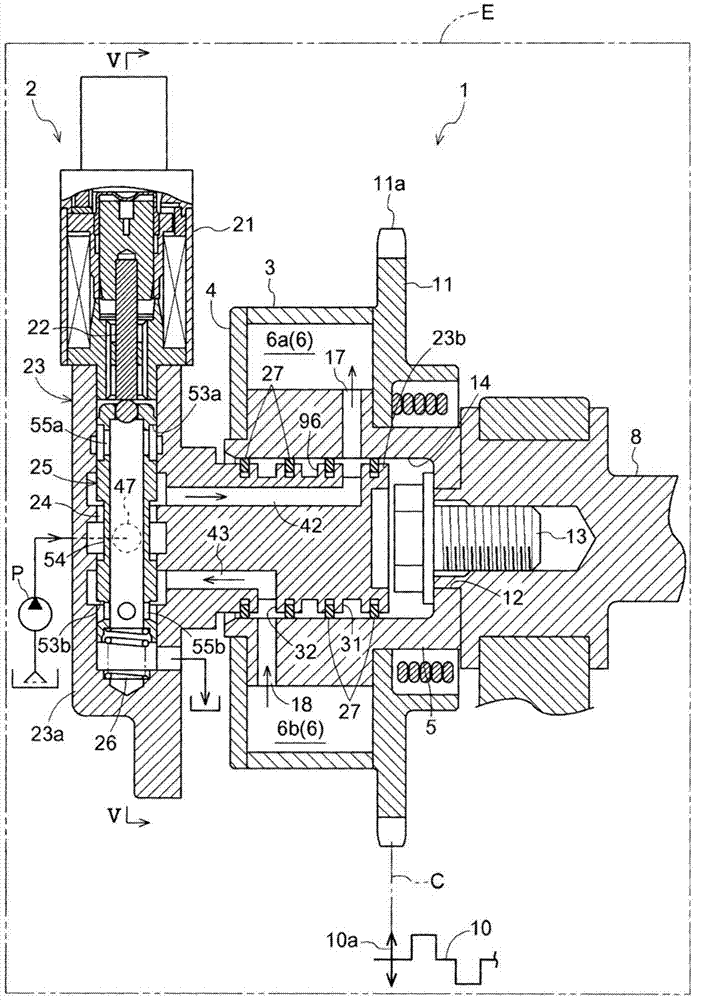

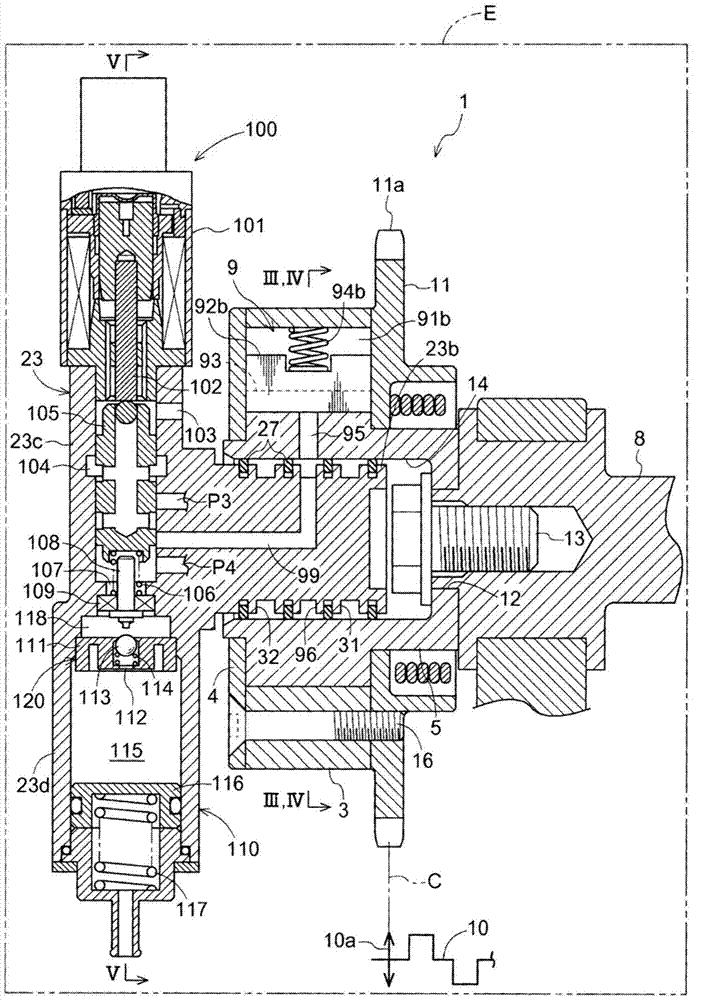

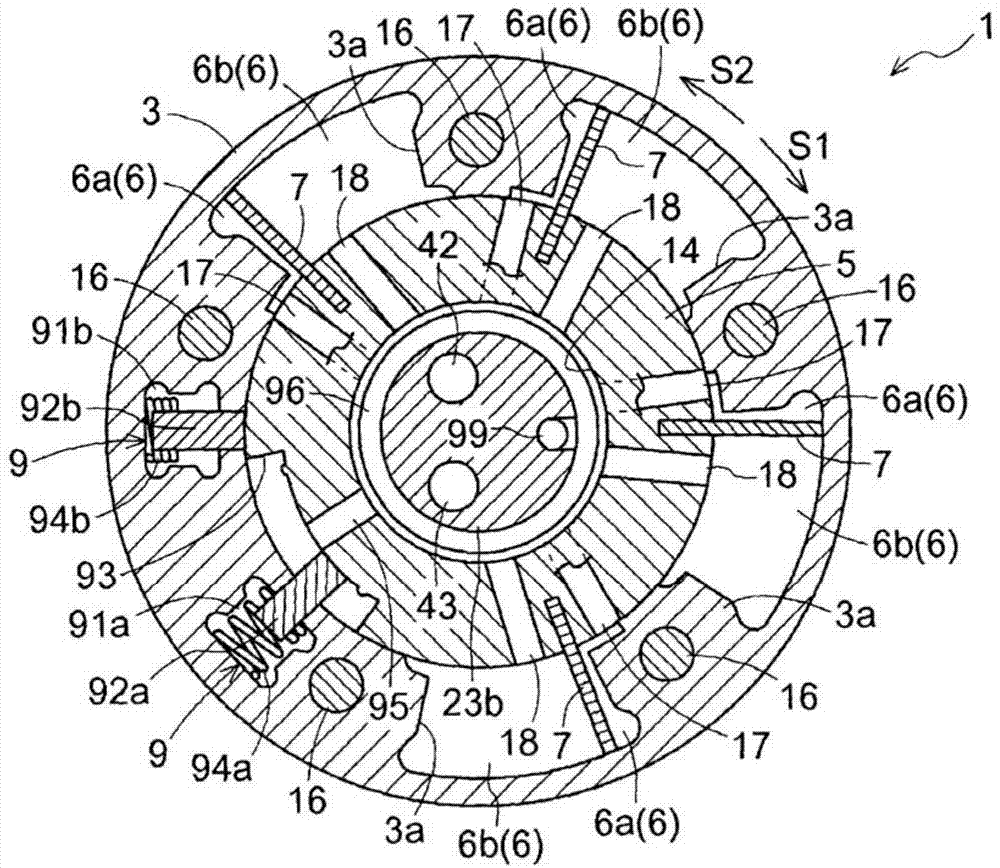

[0028] will refer to figure 1 The valve timing control device 1 according to the first embodiment is described through FIG. 6 .

[0029] Such as figure 1 and figure 2 As shown, the valve timing control device 1 includes an outer rotor 3 as a driving-side rotating member and an inner rotor 5 as a driven-side rotating member. The outer rotor 3 rotates synchronously with a crankshaft 10 of the engine E as an internal combustion engine. The inner rotor 5 is provided coaxially with the outer rotor 3 to rotate synchronously with a camshaft 8 for opening and closing valves of the engine E. As shown in FIG.

[0030] The inner rotor 5 is integrally assembled on the end of a camshaft 8 serving as a rotating shaft of a cam for controlling opening and closing of an intake valve or an exhaust valve of the engine E. The inner rotor 5 coaxially includes a recess 14 recessed from the side facing the front plate 4 . A fixing hole 12 is formed at the bottom surface of the recess 14 to pen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com