Integrated hydraulic transformer

A hydraulic transformer, integrated technology, applied in the field of hydraulic components, can solve the problems of large noise and small range of voltage regulation ratio of the transformer, and achieve the effect of eliminating noise, eliminating throttling loss, and simplifying the oil circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

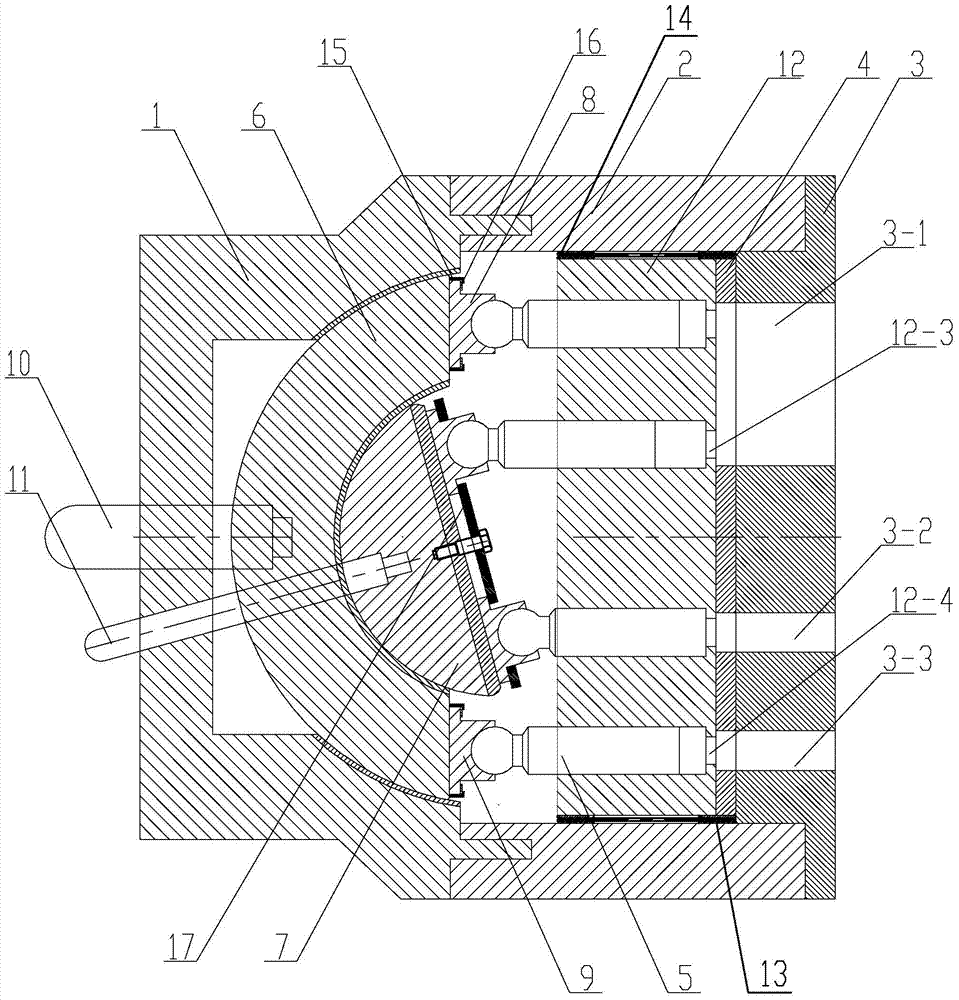

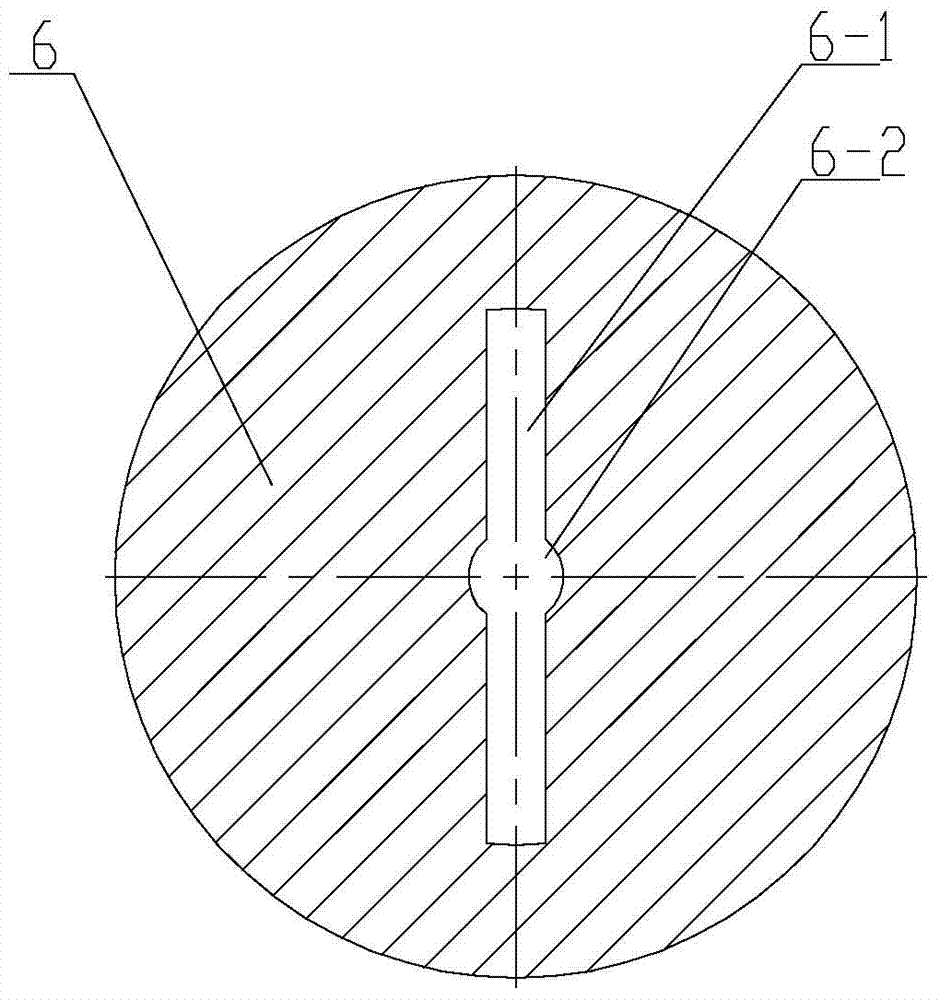

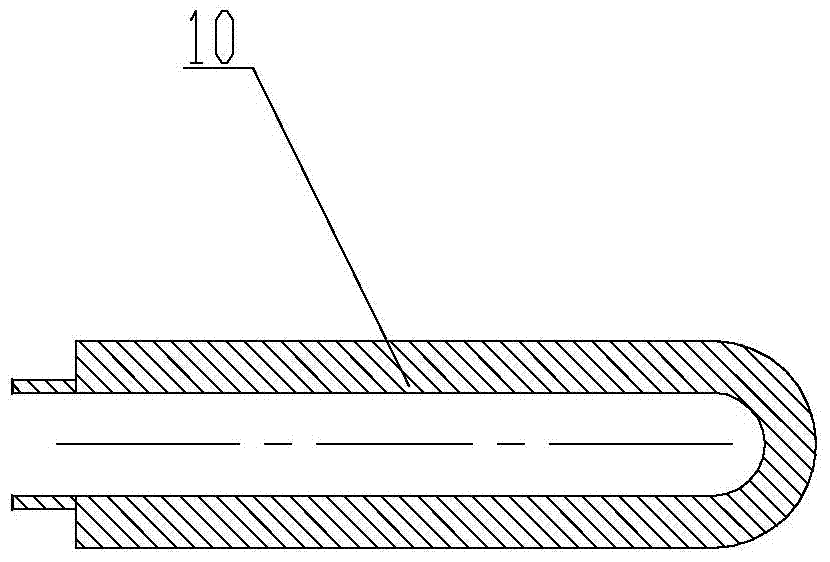

[0015] Specific embodiment one: combination Figure 1-Figure 6 To illustrate this embodiment, this embodiment includes a left end cover 1, a housing 2 and a right end cover 3. The left end cover 1, the housing 2 and the right end cover 3 are connected in sequence from left to right, and the inside constitutes a closed cavity of the hydraulic transformer. The hydraulic transformer also includes a valve plate 4, an outer annular swash plate 6, an inner annular swash plate 7, an outer sliding shoe 8, an inner sliding shoe 9, an outer swash plate adjusting rod 10, an inner swash plate adjusting rod 11, a cylinder body 12 and more There are two plungers 5, the outer annular swash plate 6 is rotatably arranged in the left end cover 1, the inner annular swash plate 7 is arranged on the outer annular swash plate 6, and the inner annular swash plate 7 is arranged concentrically with the outer annular swash plate 6, and the outer swash plate The adjusting rod 10 passes through the left e...

specific Embodiment approach 2

[0017] Specific implementation manner two: combination figure 1 Explain that the right end cover 3 of this embodiment is provided with a first pressure notch 3-1, a second pressure notch 3-2, and a third pressure notch 3-3. The first pressure notch 3-1, The second pressure notch 3-2 and the third pressure notch 3-3 are both arc-shaped pressure notches, and the first pressure notch 3-1 is located on one side of the center line of the right end cover 3, and the second pressure notch 3 -2 and the third pressure notch 3-3 are located on the other side of the center line of the right end cover 3. The purpose of this embodiment is to facilitate the overall operation of the hydraulic transformer. The technical features not disclosed in this embodiment are the same as the first embodiment.

specific Embodiment approach 3

[0018] Specific implementation mode three: combination figure 1 , Figure 4 with Figure 5 It is explained that the distribution plate 4 of this embodiment is provided with an integrated notch 4-1, a first sub-notch 4-2, and a second sub-notch 4-3, and the integrated notch 4-1 and the first sub-notch 4 -2 and the second sub-notch 4-3 respectively match the structure and size of the first pressure notch 3-1, the second pressure notch 3-2, and the third pressure notch 3-3. The technical features not disclosed in this embodiment are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com