High-speed gearbox sealing device and high-speed gearbox with same

A sealing device and gearbox technology, applied in the field of rail vehicle drive train, can solve the problems that the gearbox is difficult to meet the application requirements of higher speed grades, it is difficult to meet the limit and light weight requirements of the gearbox, and the axial sealing size of the sealing device is large. , to achieve the effect of improving processing technology, compact structure and meeting design requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

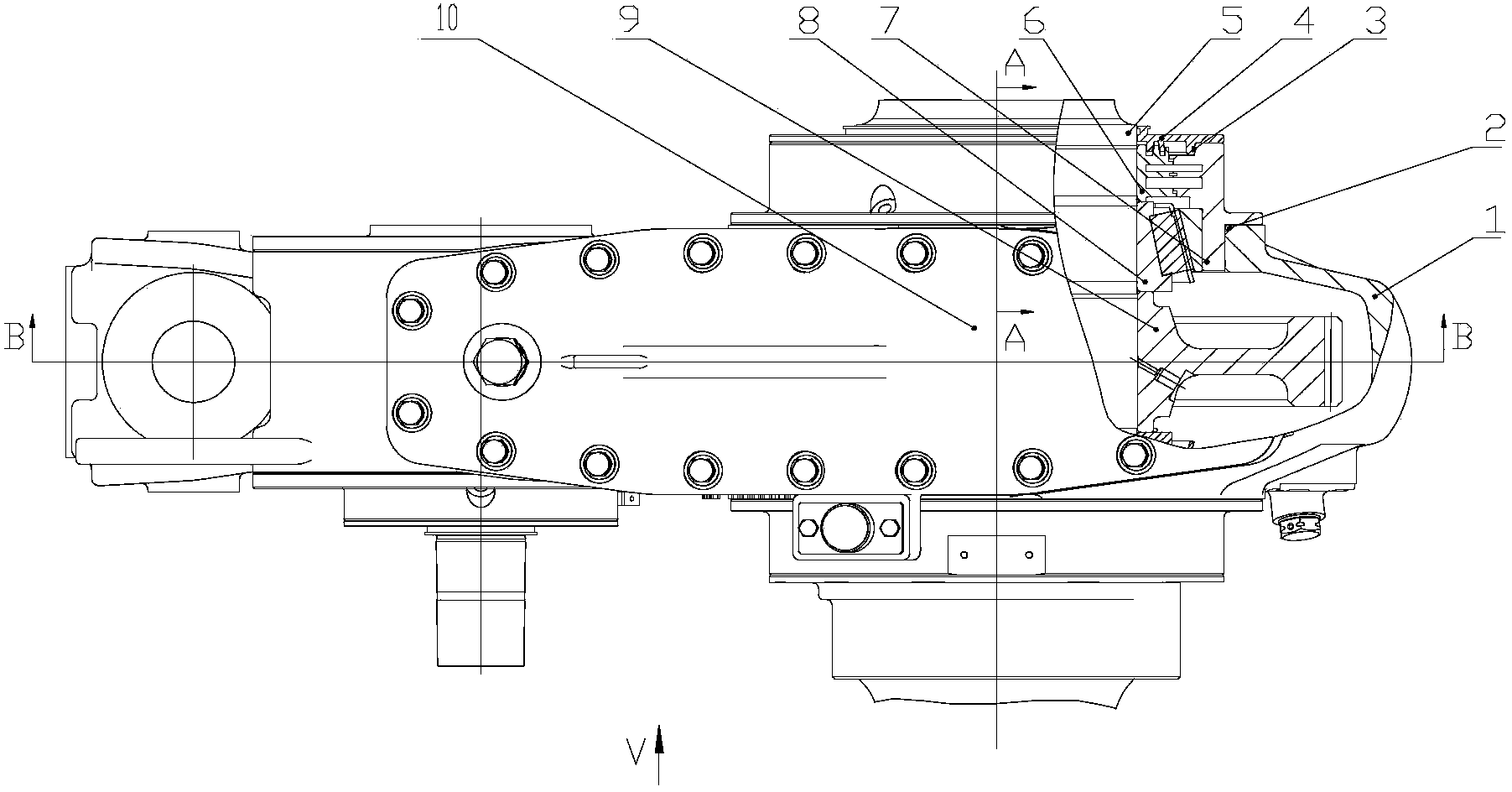

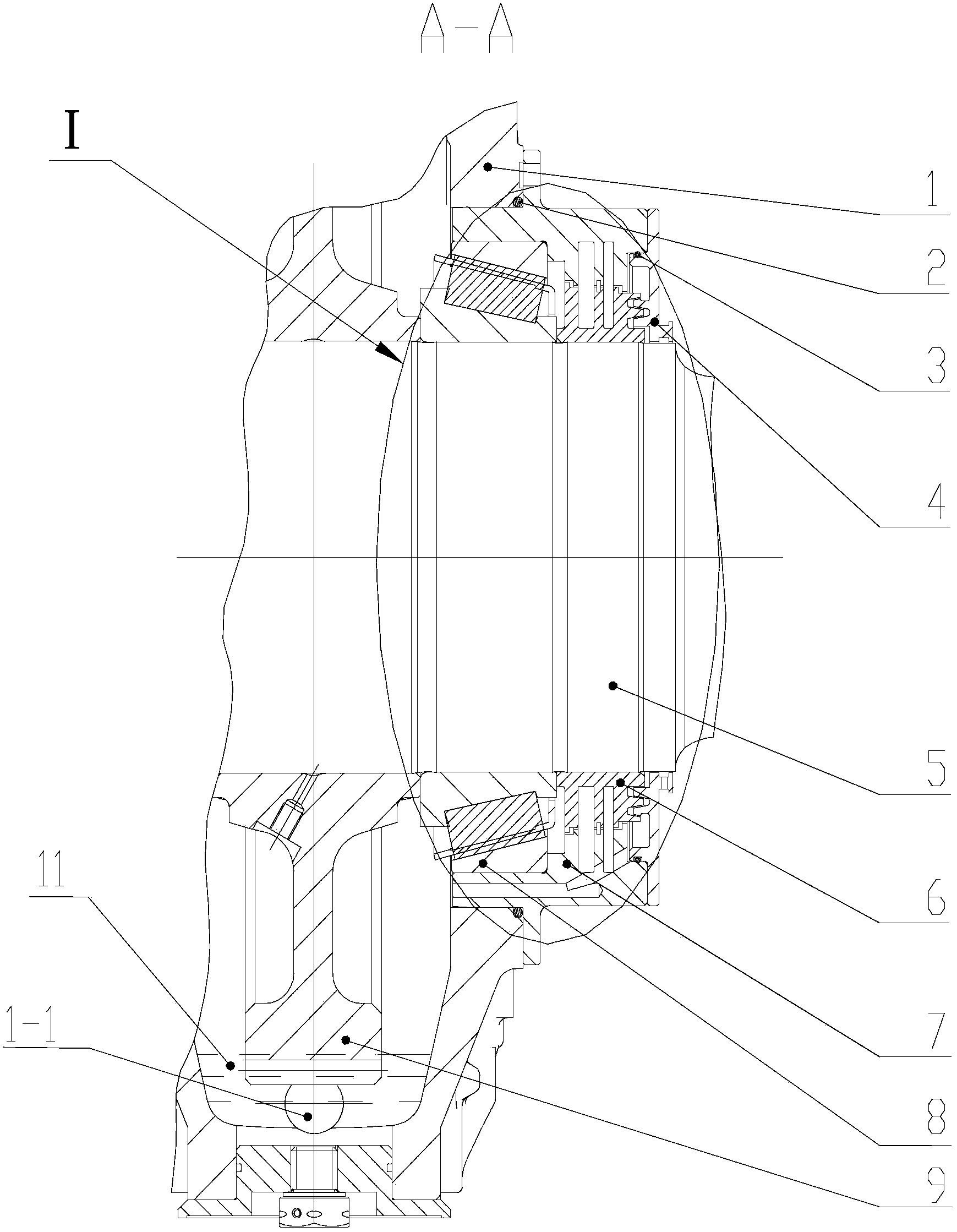

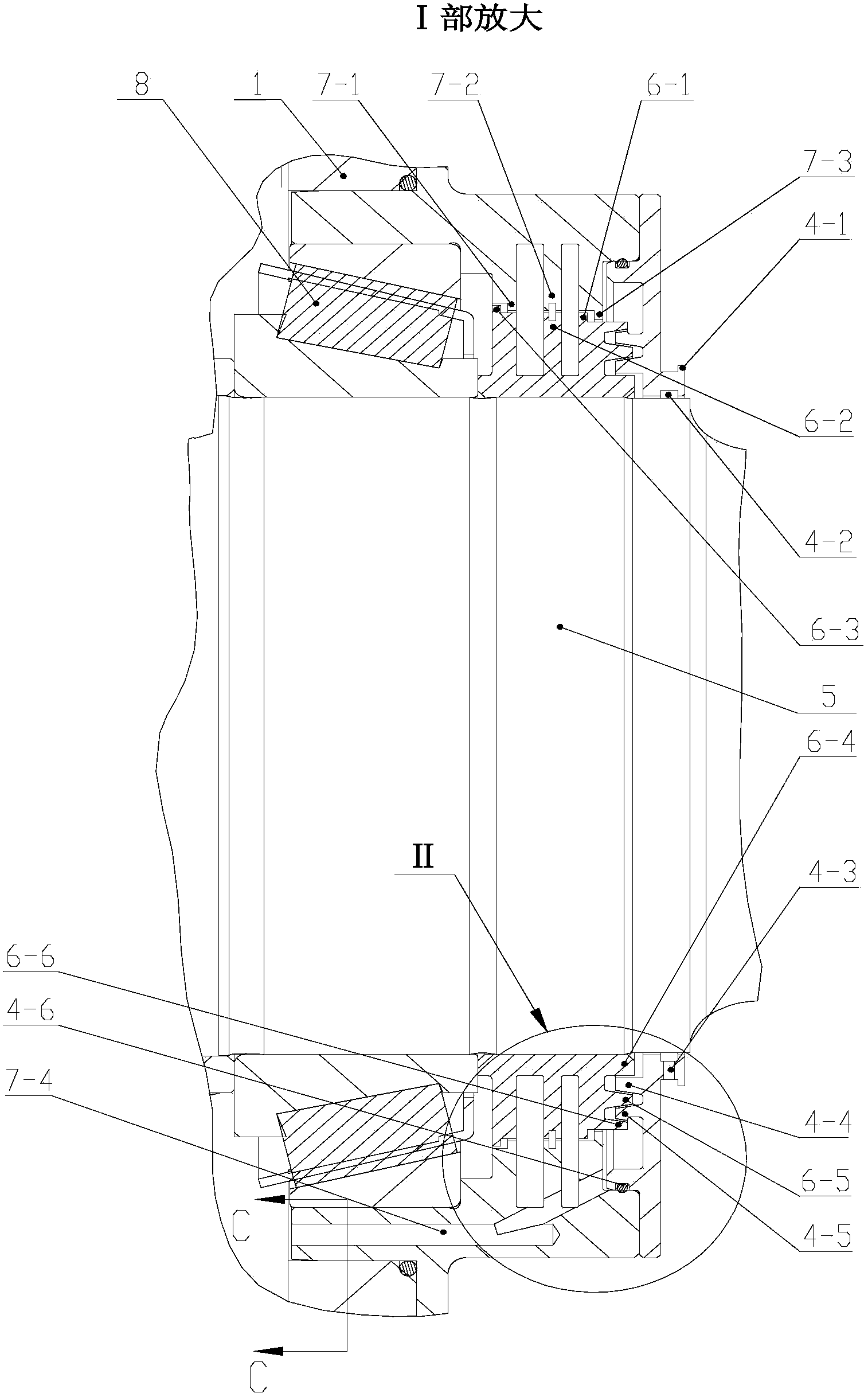

[0035] This embodiment discloses a high-speed gearbox sealing device, such as figure 1 , figure 2As shown, the sealing ring 6 set on the shaft 5, the bearing seat 7 installed on the box body 1, the sealing end cover 4 installed on the bearing seat 7, and the first O-ring sealing ring set on the bearing seat 7 2. It is composed of the second O-shaped sealing ring 3 sleeved on the sealing end cover 4 . The bearing seat 7 is provided with an inner hole for installing the bearing 8 . The sealing ring 6 and the bearing 8 are both sleeved on the shaft 5 and rotate together with the shaft 5 at high speed. The O-shaped seal ring 2 is sleeved on the bottom of the bearing seat 7, and is against the casing 1. The sealing device is provided with a plurality of protrusions, and the protrusions are respectively arranged on the bearing seat 7, the sealing ring 6, and the sealing end cover 4, which reduces the complexity and processing difficulty of the parts and improves the processabili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com