Air sealing device

A technology of air sealing and sealing seat ring, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of lubrication and oil mist river environmental pollution, etc., achieve safe use, good sealing effect, and reduce oil throwing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the shape, structure and characteristics of the present invention, preferred embodiments will be listed below and described in detail with reference to the accompanying drawings.

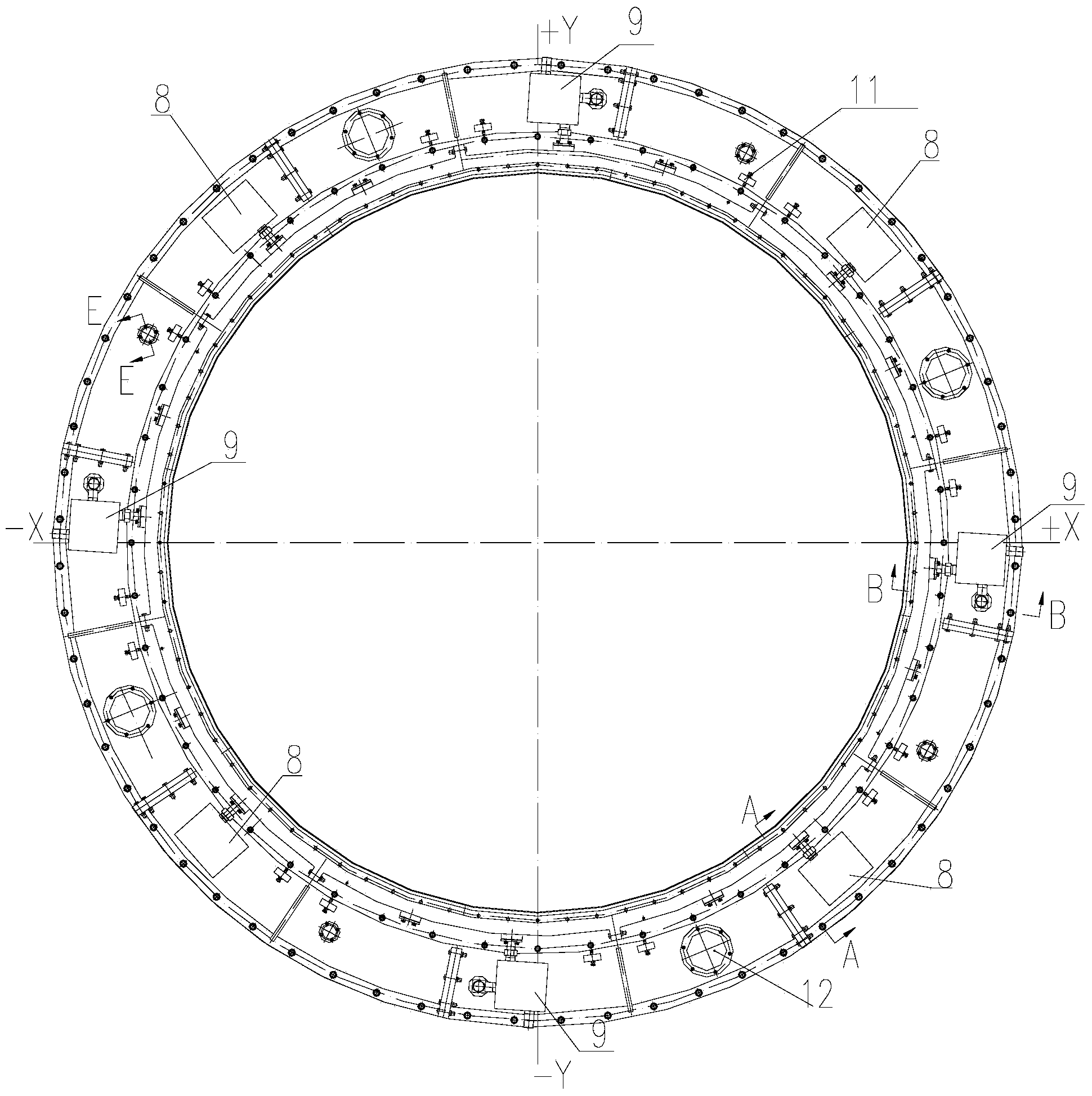

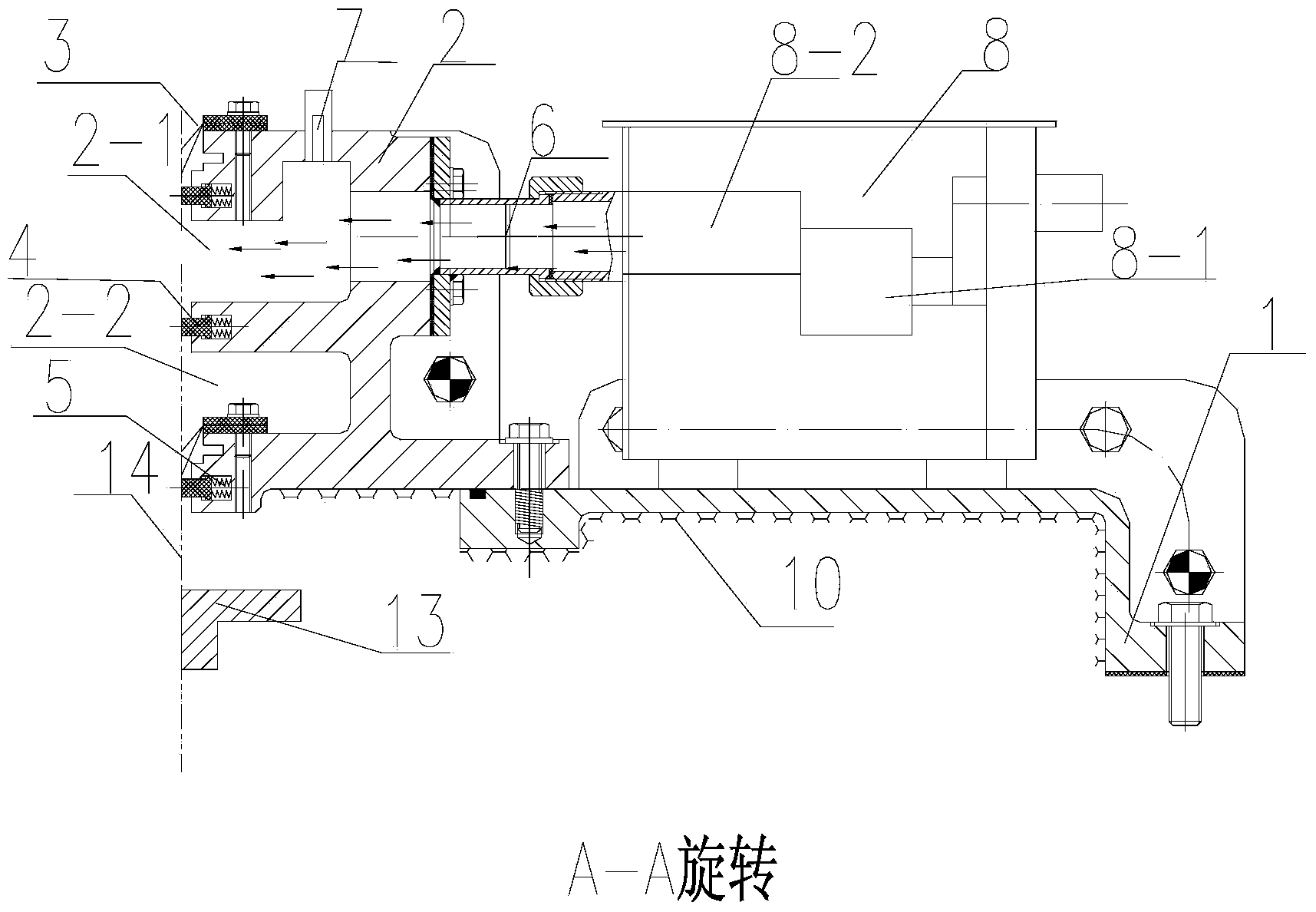

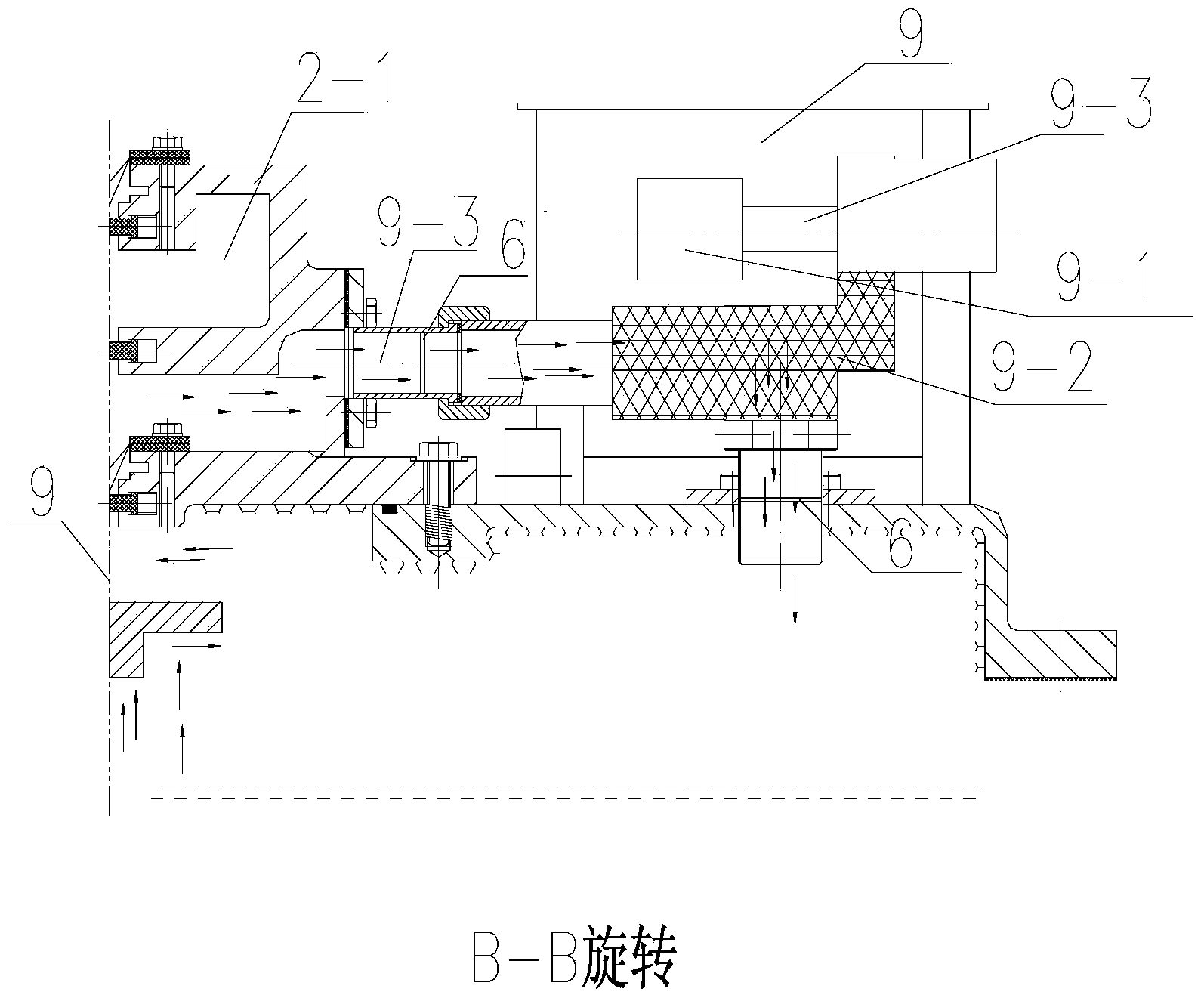

[0022] An air-tight device of the present invention includes an air delivery device 8 and an oil absorption mist treatment device 9, the air delivery device 8 includes an air delivery pipe 8-2 and an air delivery device motor 8-1 connected to the air delivery pipe 8-2. The sealing seat 2 has an upper chamber 2-1 and a lower chamber 2-2. One end of the air supply pipe 8-2 is connected to one side of the upper chamber 2-1 of the sealing seat ring 2 for supplying air to the upper chamber 2-1 of the sealing seat ring 2, and the other end communicates with the outside atmosphere. A gravity one-way valve 6 is installed in the air supply pipe 8-2. When the air supply device 8 stops working, the gravity one-way valve 6 closes the air supply pipe 8-2; Said gravity one-wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com