Device simulating firework spraying effect

A technology of spraying and equipment, which is applied to the installations, entertainment, and simulated fireworks for theaters, circuses, etc. To achieve the effect of adjusting the change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

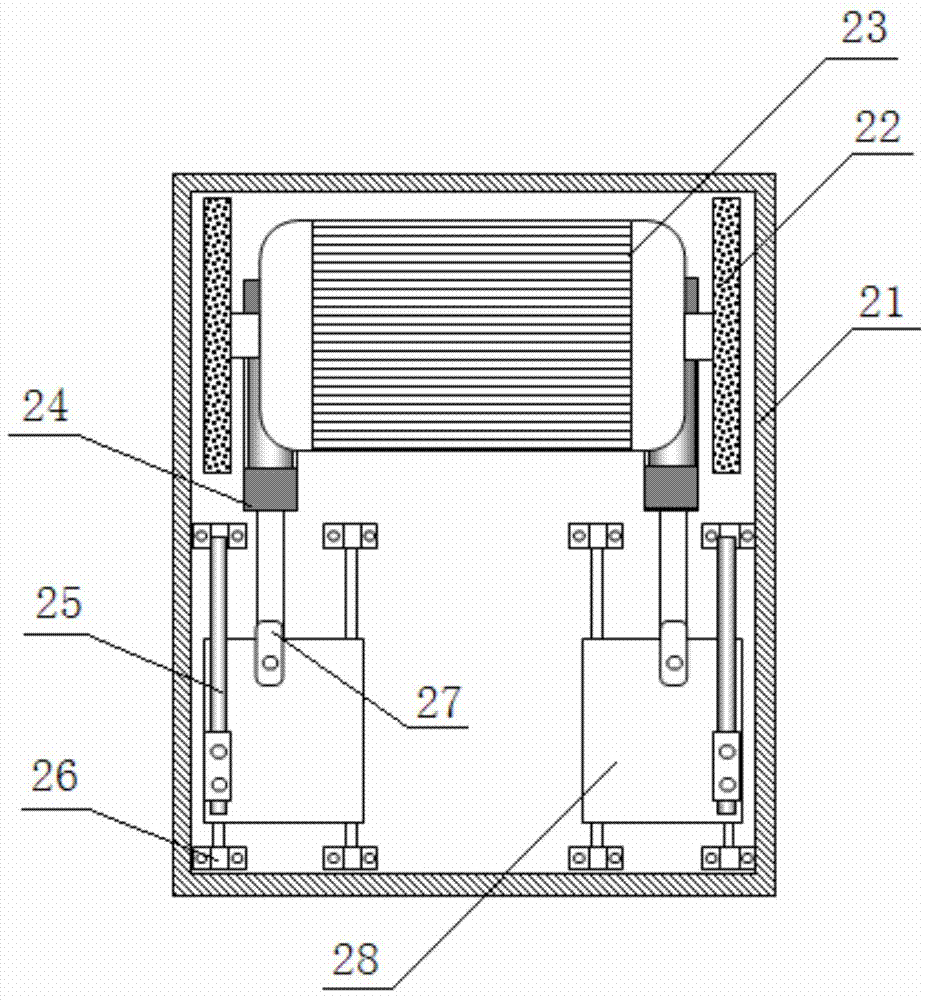

[0010] Embodiment 1: see figure 1 , reflecting a specific structure of the present invention, the equipment for imitating flower spraying effects adopts a structure with a motor and two spraying heads, including a housing 21 provided with a flower spraying port, a control cable, and a manipulator. 21 is equipped with a color-making metal rod 25, an electric grinding wheel 22 and its driving motor 23. The color-making metal rod 25 is installed on a base 28, and the base 28 is installed on a guide rail 26. The base 28 is connected to The part 27 is connected with the cylinder driving device 24, and the cylinder driving device 24 drives the color-making metal rod 25 to move linearly back and forth along the guide rail 26 toward the friction surface of the electric grinding wheel 22.

Embodiment 2

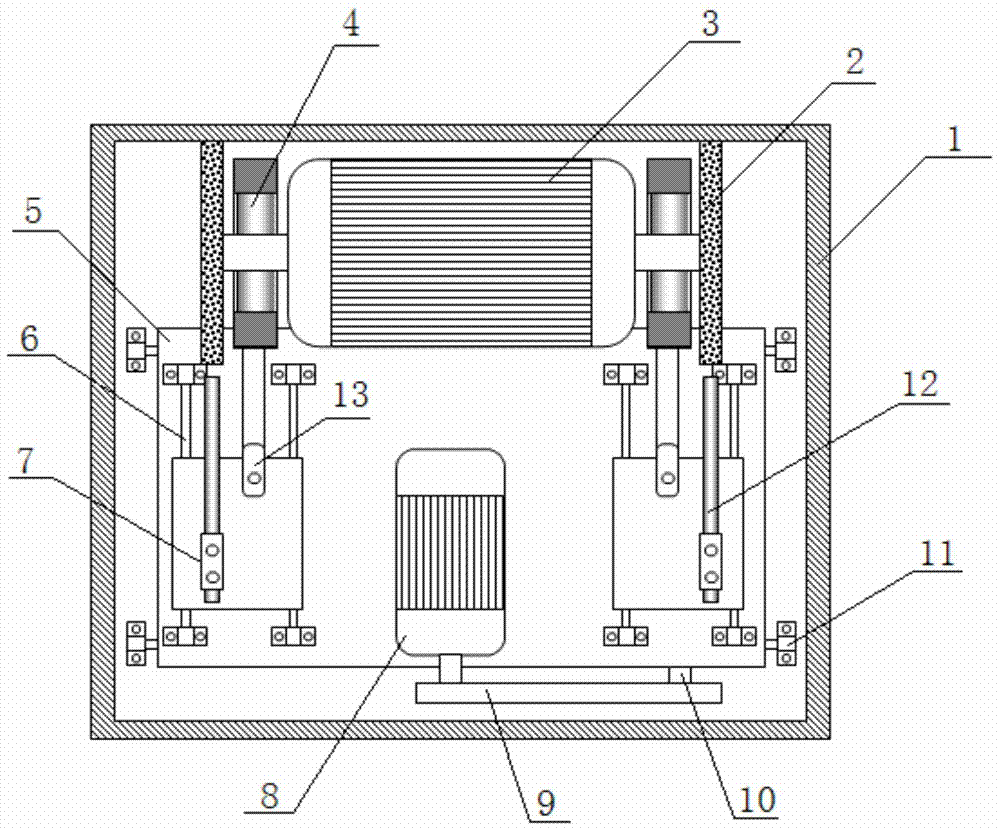

[0011] Example 2: see figure 2 , reflecting a specific structure of the present invention, the device for imitating flower spraying effects also adopts the structure of a motor with two flower spraying heads, including a housing 1 provided with a flower spraying port, a control cable, and a manipulator. The color-making metal rod 12, the electric grinding wheel 2 and its drive motor 3 are installed in the body 1, the color-making metal rod 12 is installed on the base 7, and the base 7 is installed on the guide rail 6, and the base 7 passes through The connecting piece 13 is connected with the cylinder driving device 4, and the cylinder driving device 4 drives the color-making metal rod 12 to move forward and backward linearly along the guide rail 6 toward the friction surface of the electric grinding wheel 2.

[0012] Described guide rail 6 is fixed on the base plate 5, and base plate 5 is installed on the auxiliary guide rail 11, and described base plate 5 connects auxiliary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com