Leak rate detection apparatus and method for connection position of pressure control system and spacecraft sealed compartment

A detection device and a technology of a sealed cabin, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, and by measuring the increase and decrease rate of the fluid, etc., can solve the problems of increasing test costs, leak rate detection at joints, and development progress of spacecraft products impact and other issues, to achieve the effect of ensuring development progress, ensuring reliability, and avoiding test interruption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific embodiments of the present invention are described in detail below: the specific embodiments of the present invention are implemented on the premise of the technical solutions of the present invention, and detailed embodiments and specific operation procedures are given, but the protection scope of the present invention is not limited to The following examples.

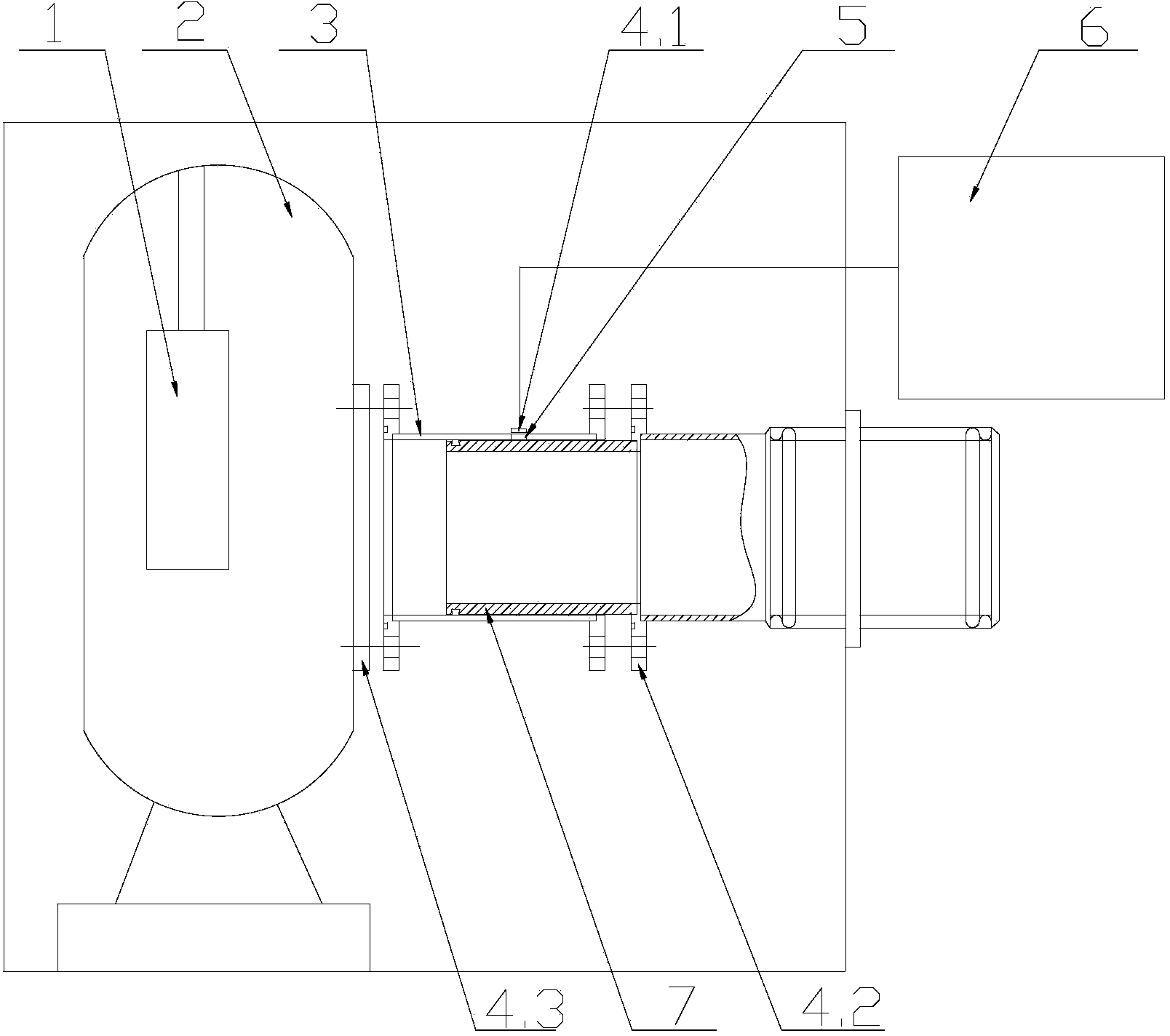

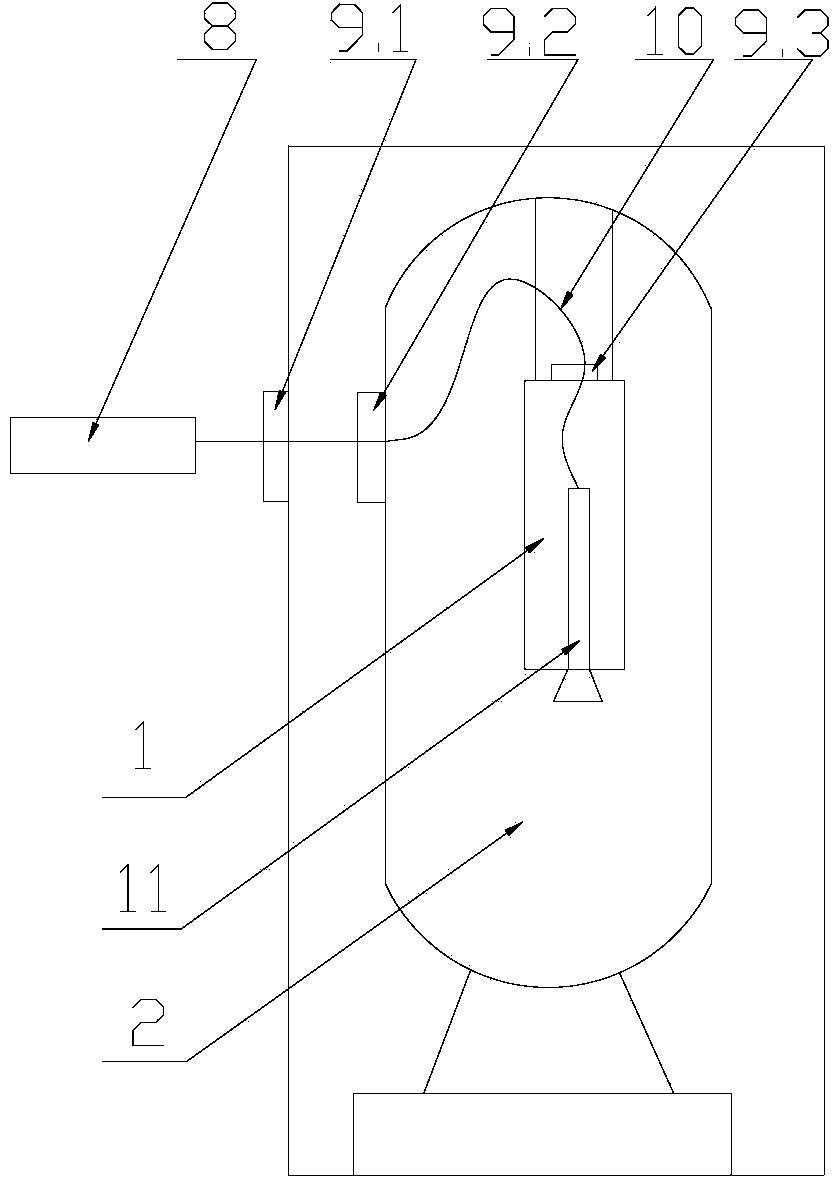

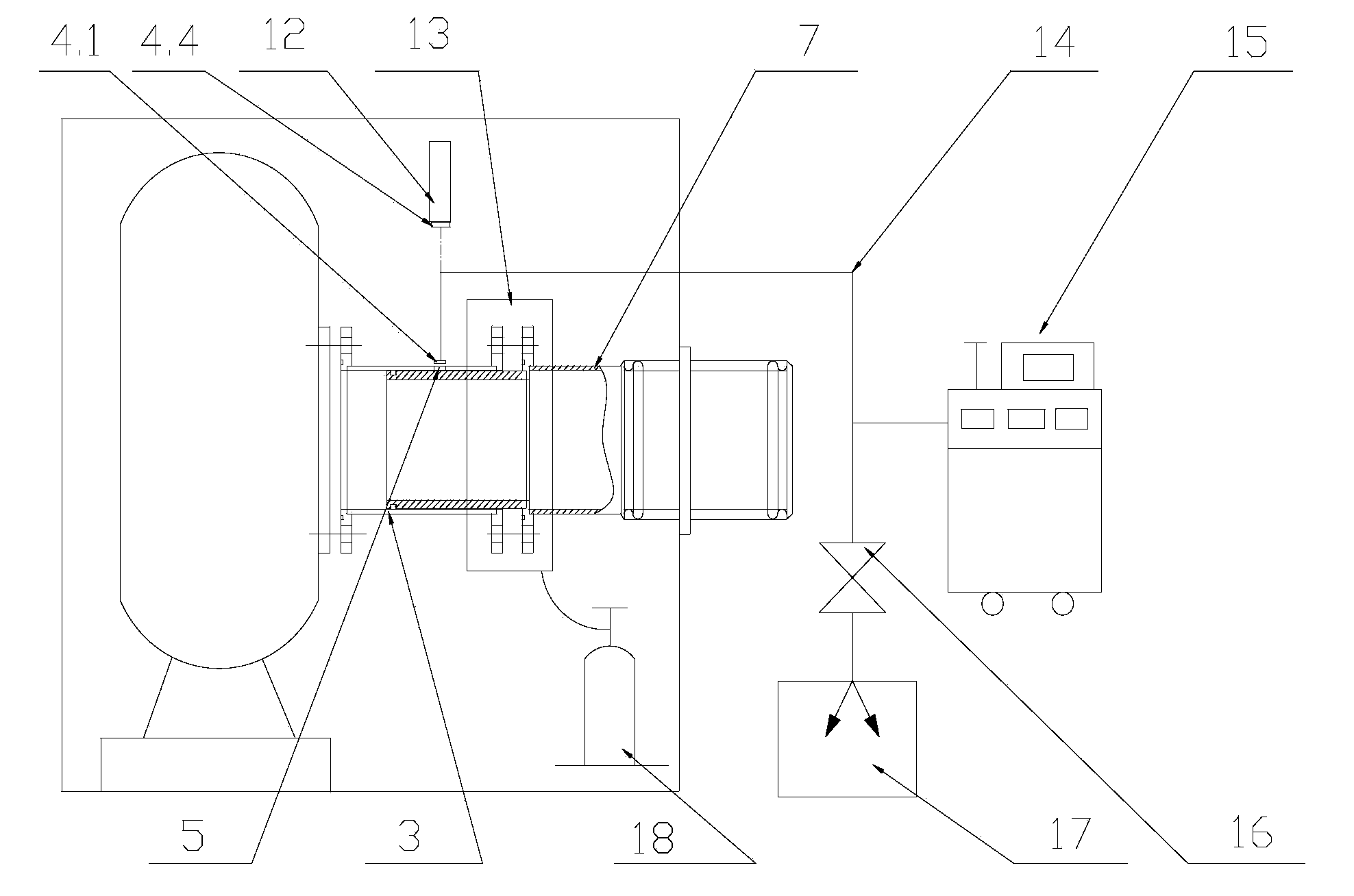

[0042] Such as figure 1 As shown, the pressure simulation control system for vacuum thermal test of the present invention and the leak rate detection device at the junction of the spacecraft airtight cabin include a high-precision vacuum measurement device ( figure 2 (Shown), spacecraft airtight cabin 2, leak rate detection tool 3, helium mass spectrometry leak detection system 6, pressure simulation control system pipeline 7, among which the leak rate detection tool 3 passes the leak detection flange 4.1, the butt flange 4.2, The adapter flange 4.3 is connected with the helium mass spectrometer leak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com