Testing device and method for thermal conductivity coefficient of material

A thermal conductivity and testing device technology, which is applied in the field of material thermal conductivity testing devices, can solve the problems of difficulty in ensuring the accuracy of material thermal conductivity testing, difficulty in temperature consistency between the upper and lower sides of the protective plate, and the large thickness range of the test piece. Edge heat loss, shorten the detection cycle, avoid the effect of easy drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments.

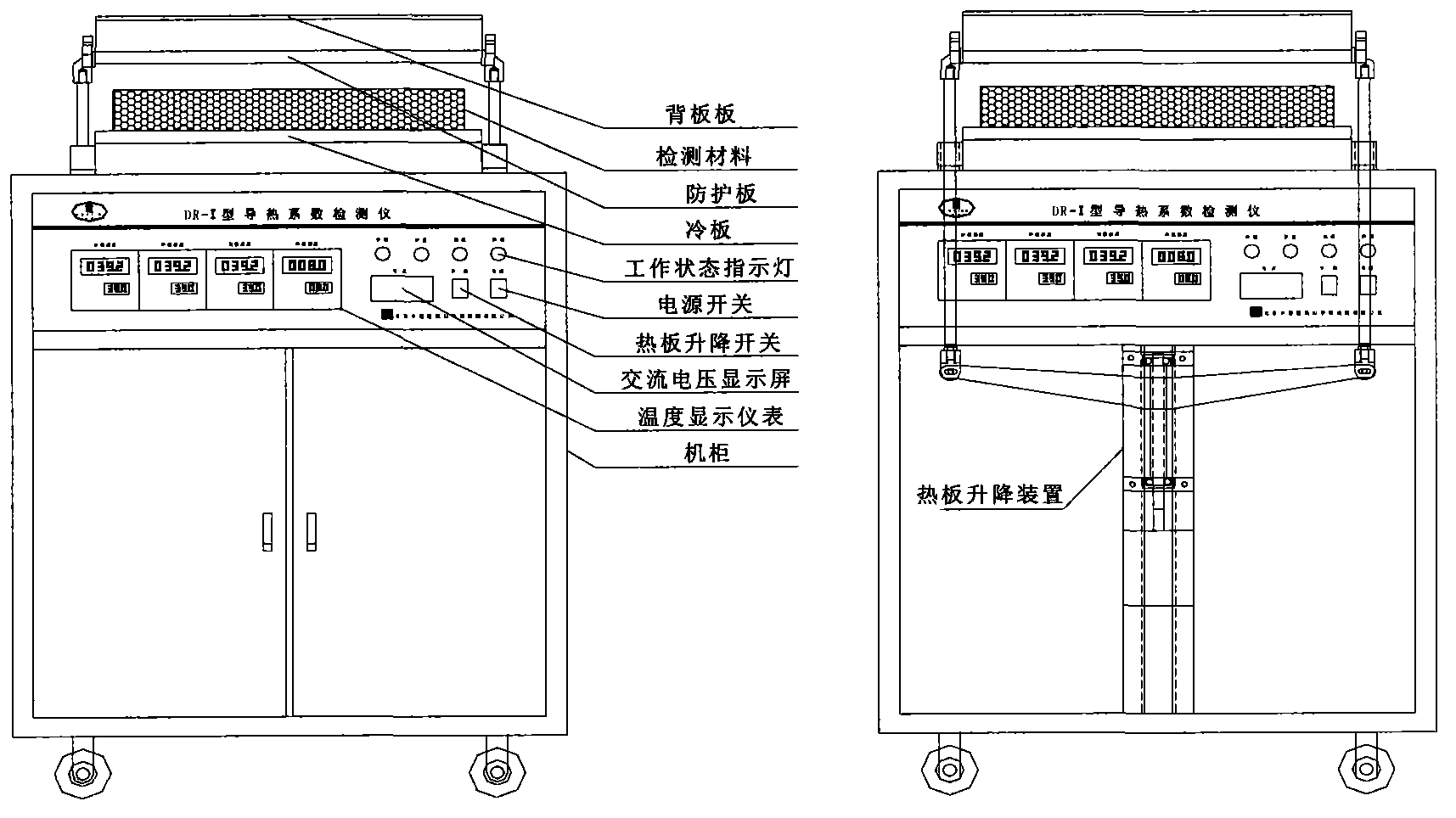

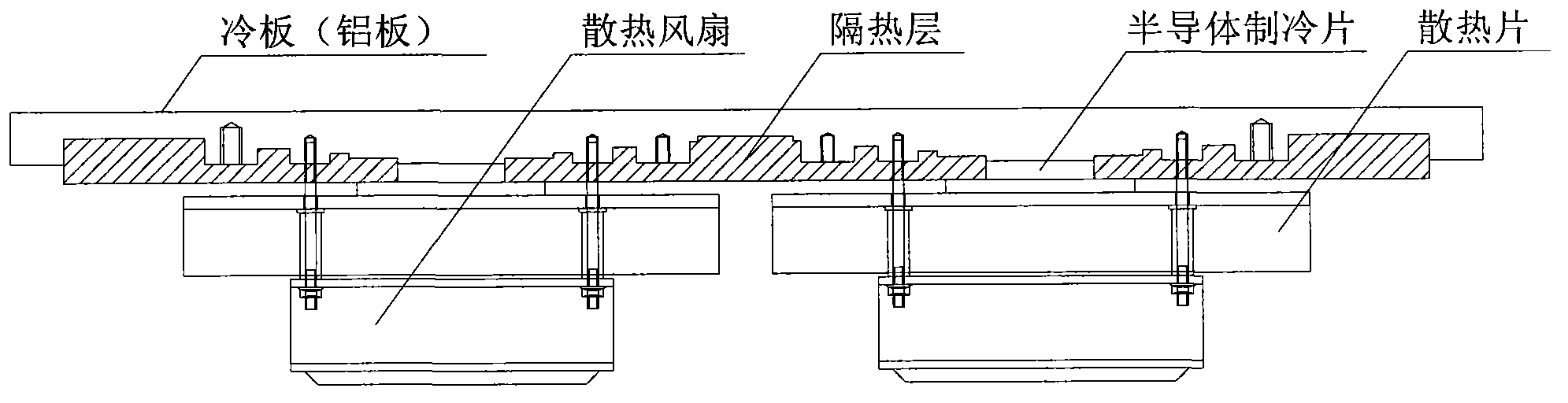

[0032] Such as Figure 1~6 As shown, the present invention is suitable for testing specimen thickness less than 100mm, thermal resistance greater than 0.1m 2 • Thermal conductivity or thermal resistance of flat material in K / W. The thermal conductivity detector includes: hot plate heating system, cold plate cooling system, electric lifting system, heat flow measurement system, electrical control and measurement system and industrial computer software control system.

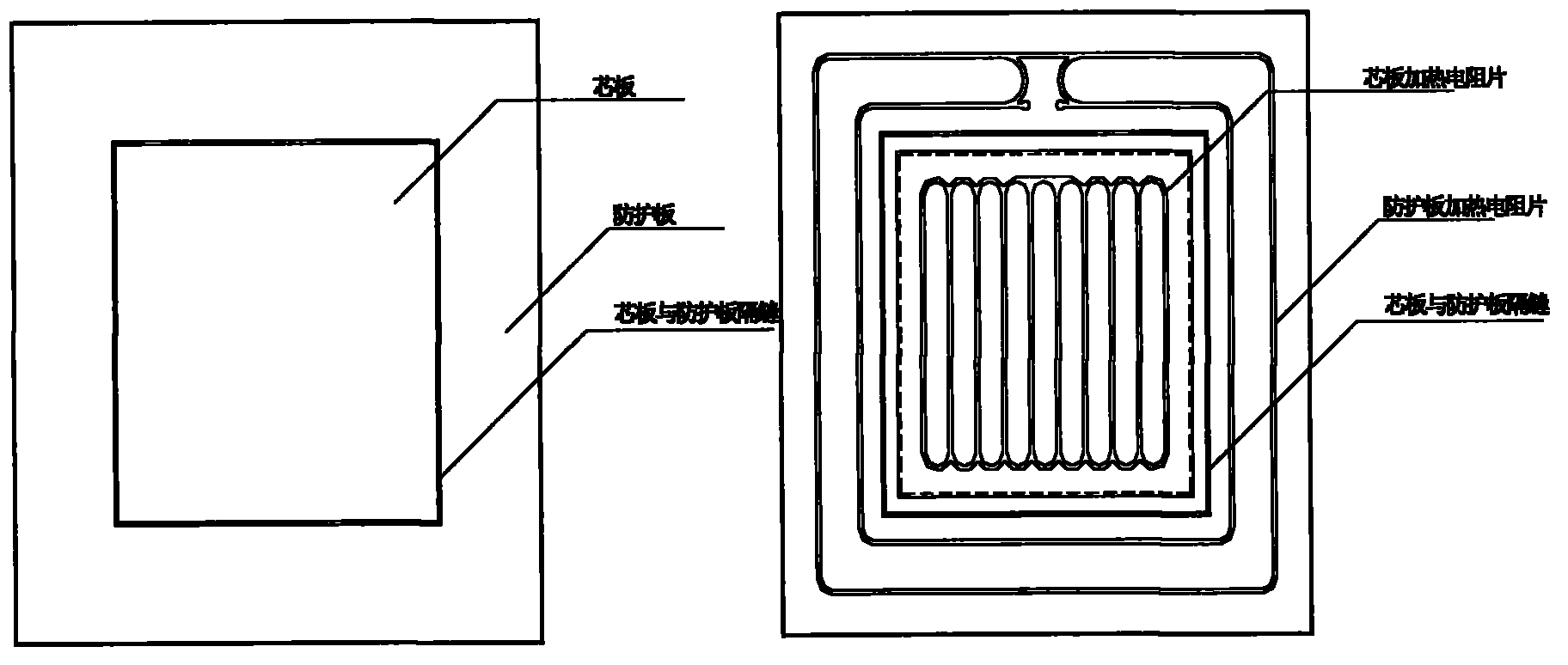

[0033] Hot plate heating systems such as figure 2 As shown, it includes a core board, a protective board and a back board, and each part uses a heating resistance sheet as a heater, and it is a double-heating surface heater, and the material of the heating board panel is aluminum alloy. Among them, the core board is the measurement unit, which is composed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com