Curved light guide plate and manufacturing method thereof

A manufacturing method and technology of a light guide plate, applied in the field of light guide plates, capable of solving problems such as changes in shape and size, environmental temperature and humidity, uneven screen brightness, and extrusion of curved light guide plates and display panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

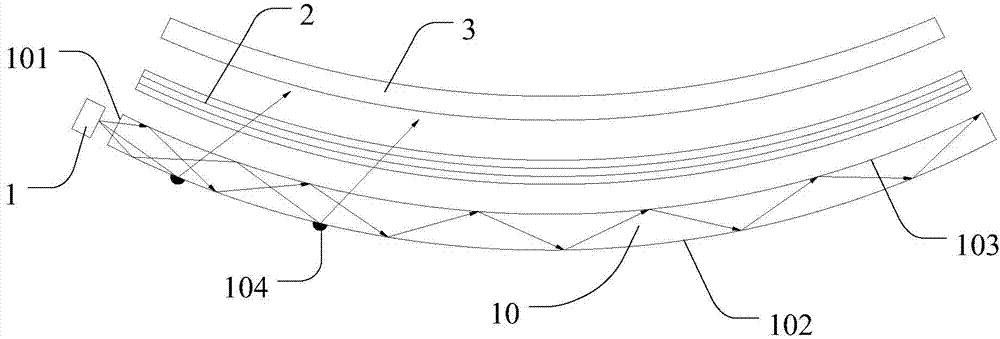

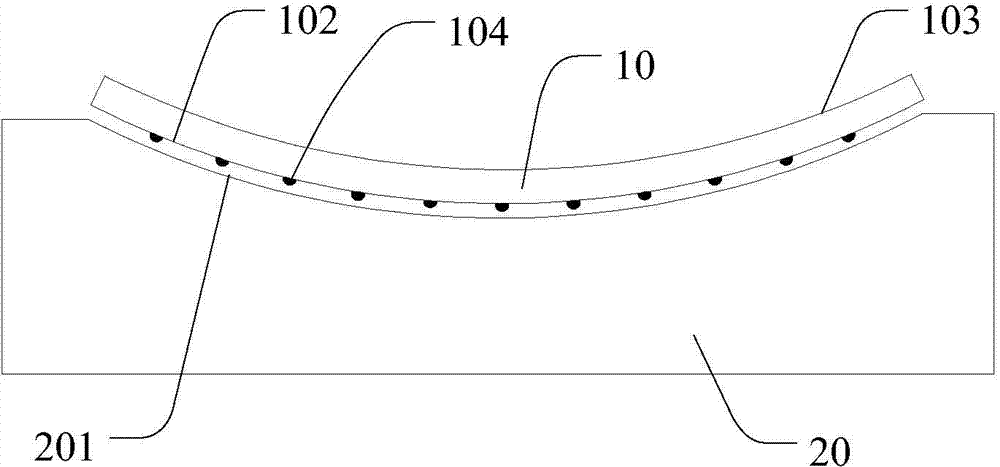

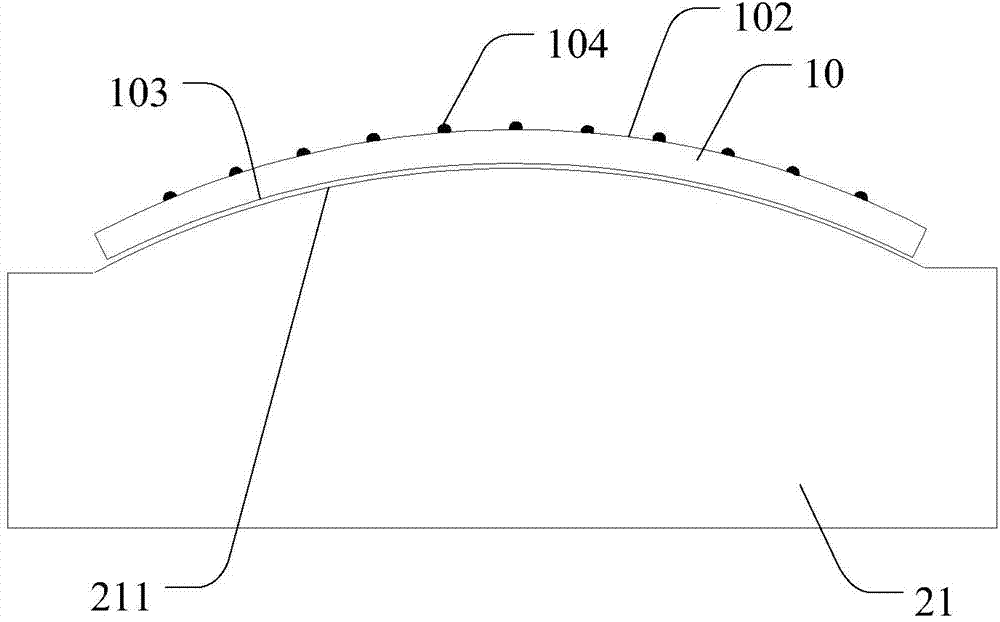

[0039] refer to figure 1 , figure 1 It is a schematic diagram of the structure of the curved light guide plate and the propagation path of light in the present invention; the curved light guide plate 10 of this embodiment includes a light incident surface 101, a first curved surface 102 and a second curved surface 103 parallel to each other, and the opposite two sides of the light incident surface 101 The sides are respectively connected to the first curved surface 102 and the second curved surface 103, and the first curved surface 102 is provided with dots 104; after the light enters from the incident surface 101 and is reflected by the dots 104, The second curved ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com