Semiconductor loading direct current motor drive platform

A DC motor and drive platform technology, applied in semiconductor/solid-state device manufacturing, electric components, circuits, etc., can solve problems such as danger, this method is not ideal, and practical operation is difficult, to reduce skill requirements, save labor costs, The effect of reducing the difficulty of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

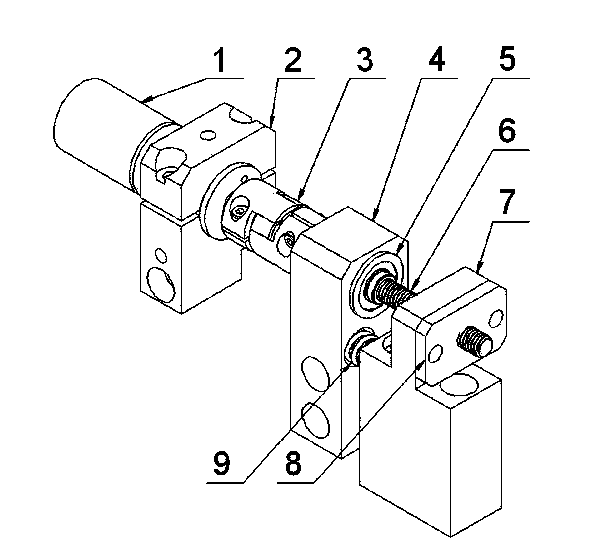

[0011] figure 1 A diagram of a DC motor drive mechanism is shown. The DC motor driving mechanism includes a protruding mechanism and a computer operating system for monitoring the protruding mechanism. The computer operating system is connected to the DC motor 1, and the DC motor 1 is fixed on the moving part through the DC motor base 2, and the coupling 3 and the screw rod 6 are used. Connect, screw rod 6 rear portion has bearing 5 supports, and front portion has adjusting nut 8, and bearing 5 and adjusting nut 8 are respectively fixed on bearing seat 4 and adjusting nut seat 7, stage clip is arranged between the two to eliminate thread clearance. Use the mouse to click on the control button on the computer operating system, the DC motor 1 is powered on to work, and the DC motor 1 stops working when the mouse is released. The number of rotations of the DC motor 1 is controlled by the length of time the button is pressed.

[0012] The size and pitch of the screw rod 6 can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com