Enhanced FINFET process overlay mark

A technology for marking and marking areas, applied in the field of semiconductors, can solve the problems of not being able to fully meet the requirements of manufacturing non-planar devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

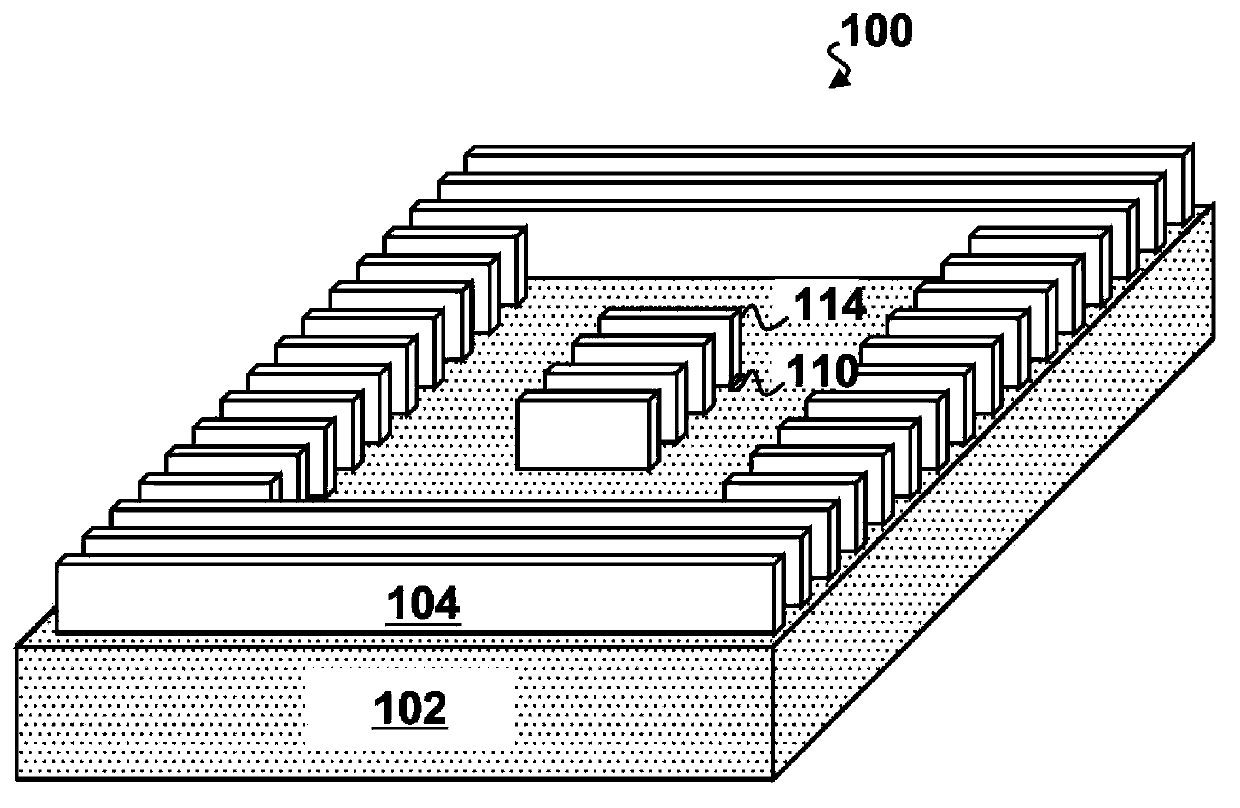

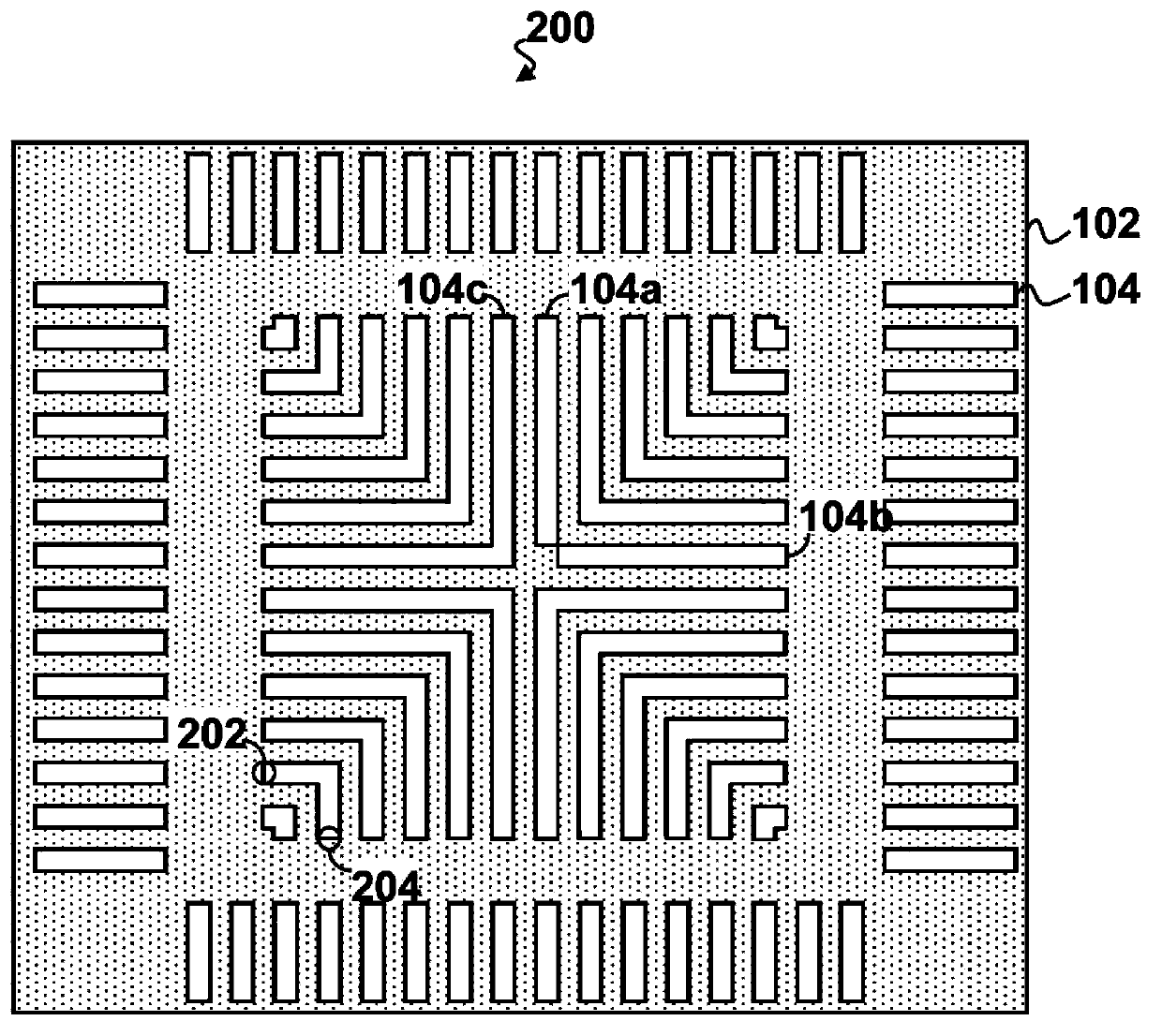

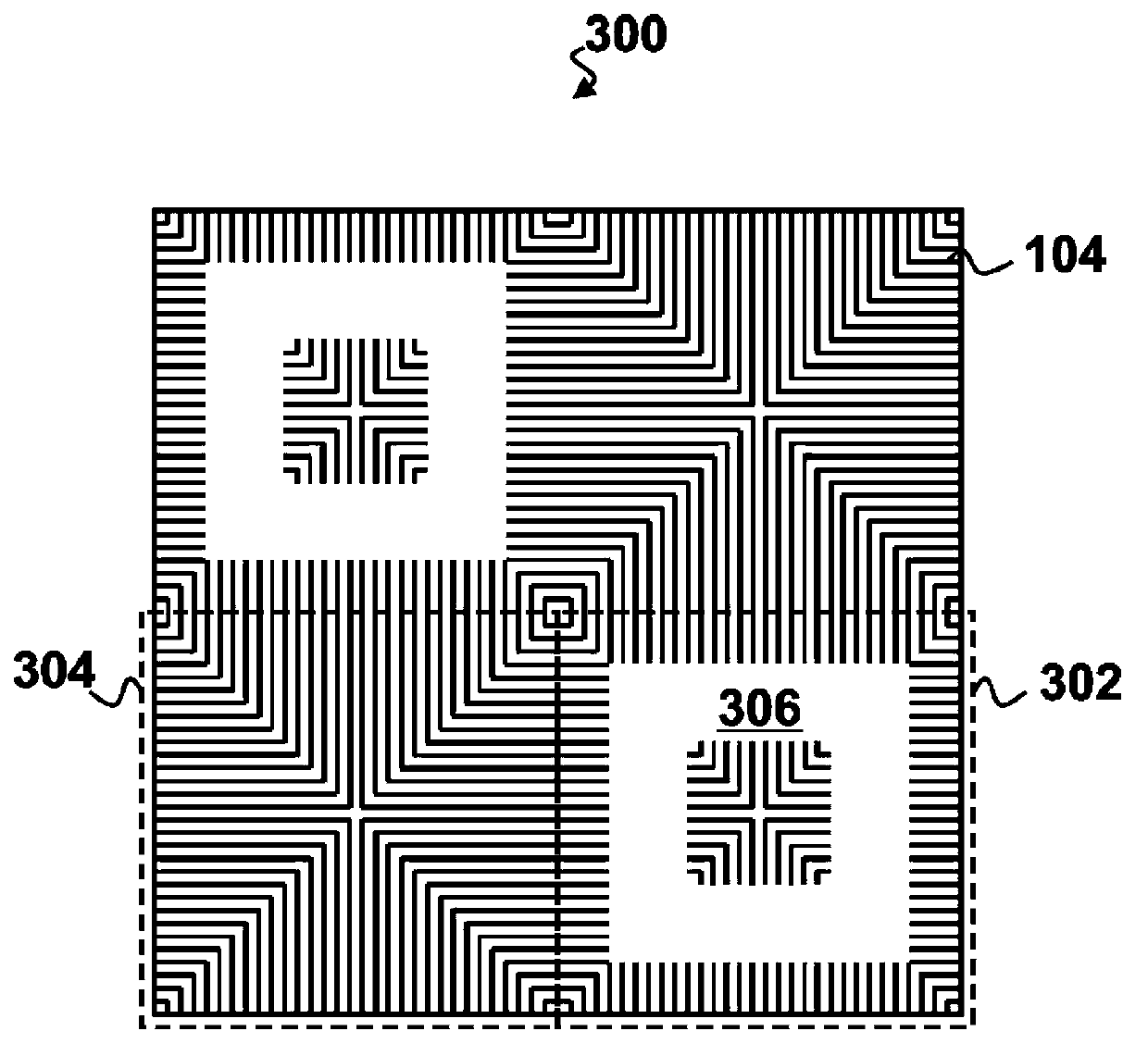

[0039]The present invention relates generally to overmarks for the manufacture of IC devices, and more particularly to overmarks suitable for the manufacture of non-planar devices and methods for making the same.

[0040] The following summary provides a number of different embodiments, or examples, to illustrate the concepts herein. Specific examples of components and arrangements are described below to simplify the present disclosure. Of course, these are merely examples and are not intended to limit the invention. For example, in the following description, forming a first component over or on a second component may include an embodiment in which the first component and the second component are formed in direct contact, and may also include that other components may be formed on the first component and the second component. An embodiment in which the first part and the second part are not in direct contact between the two parts. Additionally, the invention may repeat refer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com