Flexible battery pack

A flexible battery pack and battery pack technology, applied in battery pack components, small-sized batteries/battery packs, large-size batteries/battery packs, etc., can solve the bending degree and capacity limitations of battery packs, flexible battery packs Irregular bending, reducing battery energy density and other issues, to achieve the effect of reducing irregular bending, prolonging battery life, and increasing energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

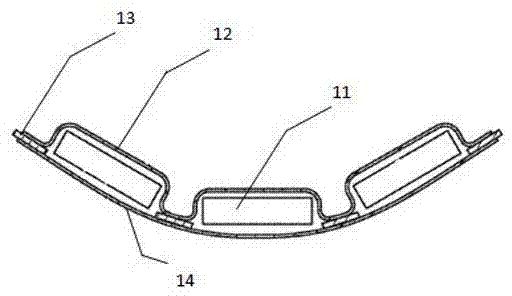

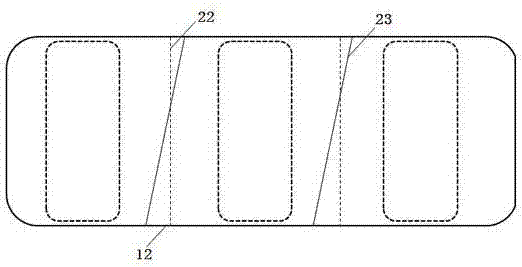

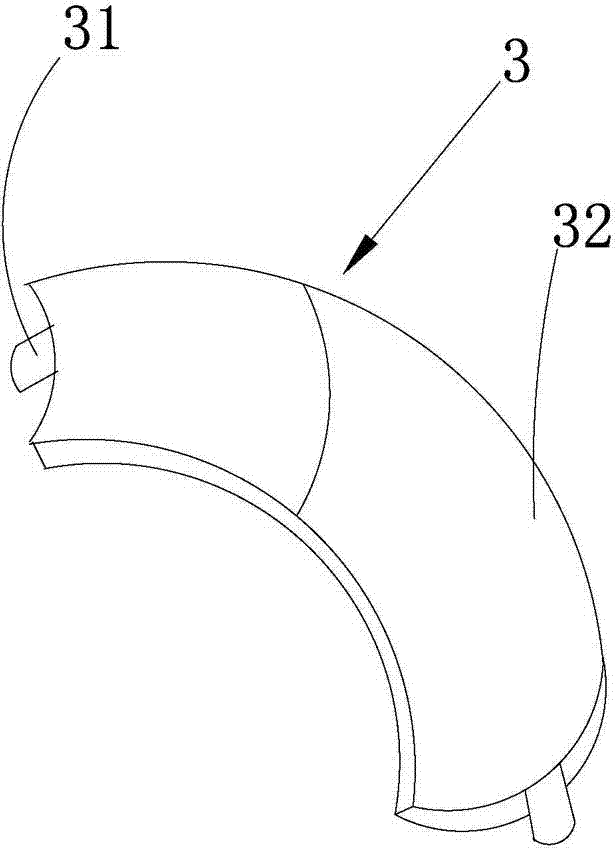

[0044] Such as Figure 5As shown, the flexible battery pack provided by this embodiment includes a packaging film 5, an electrolyte filled in the packaging film 5, and at least two electrically connected electric cores packaged in the packaging film 5, and the electric core includes a flexible battery pack. Core 3 and two conventional batteries 4, the flexible battery 3 has a bendable arc of 60° (that is, the flexible battery 3 can be bent within the range of 0~60°), and the flexible battery 3 is located between the two conventional batteries 4 In between, the flexible cells 3 are respectively connected in series with two conventional cells 4, the packaging film 5 is sealed by a sealant layer 6, the material of the sealant layer 6 is polypropylene, and the sealant layer 6 is bonded to the package by bonding and screen printing. The film 5 is packaged, and the packaging film 5 between the flexible cell 3 and the conventional cell 4 is provided with a narrowing 7 for stress rele...

Embodiment 2

[0048] Such as Figure 8 As shown, the difference from Example 1 is that the bendable arc of the flexible cell 3 is 120° (that is, the flexible cell 3 can be bent within the range of 0-120°), and the material of the sealant layer 6 is polyimide , and there is a buffer rubber layer 8 between the flexible battery 3 and the conventional battery 4, and the material of the buffer rubber layer 8 is acrylic resin to ensure that the flexible battery 3 and the conventional battery 4 are in the mutual extrusion process Stress relief, thereby reducing safety concerns. And the flexible battery cells 3 are respectively connected in parallel with two conventional battery cells 4 .

[0049] The rest are the same as in Embodiment 1, and will not be repeated here.

[0050] When preparing the flexible battery pack of this embodiment, the flexible battery 3 and the two conventional batteries 4 can be placed in the packaging film 5 respectively, and the flexible battery 3 is placed between the ...

Embodiment 3

[0052] Such as Figure 9 As shown, the difference from Example 1 is that the bendable arc of the flexible cell 3 is 30° (that is, the flexible cell 3 can be bent within the range of 0-30°), and the material of the sealant layer 6 is acrylic resin , and the battery cell includes a flexible battery cell 3 and a conventional battery cell 4, and the flexible battery cell 3 and the conventional battery cell 4 are connected in series.

[0053] The rest are the same as in Embodiment 1, and will not be repeated here.

[0054] When preparing the flexible battery pack of this embodiment, the flexible battery cell 3 and the conventional battery cell 4 can be placed in the packaging film 5 first, and the flexible battery tab 31 and the conventional battery tab 41 both protrude from the packaging. In the film 5, and the flexible battery tab 31 and the conventional battery tab 41 of the conventional battery 4 are connected in series, after the top sealing operation is performed on the pack...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com