Large phased array radar antenna frame structure and manufacturing method thereof

A technology of phased array radar and frame structure, which is applied in the direction of antenna support/installation device, etc., which can solve the problems of unsuitable mass production, low precision, easy deformation, etc., and achieve the effect of improving environmental adaptability, high precision and improving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will now be further described in conjunction with the embodiments and drawings:

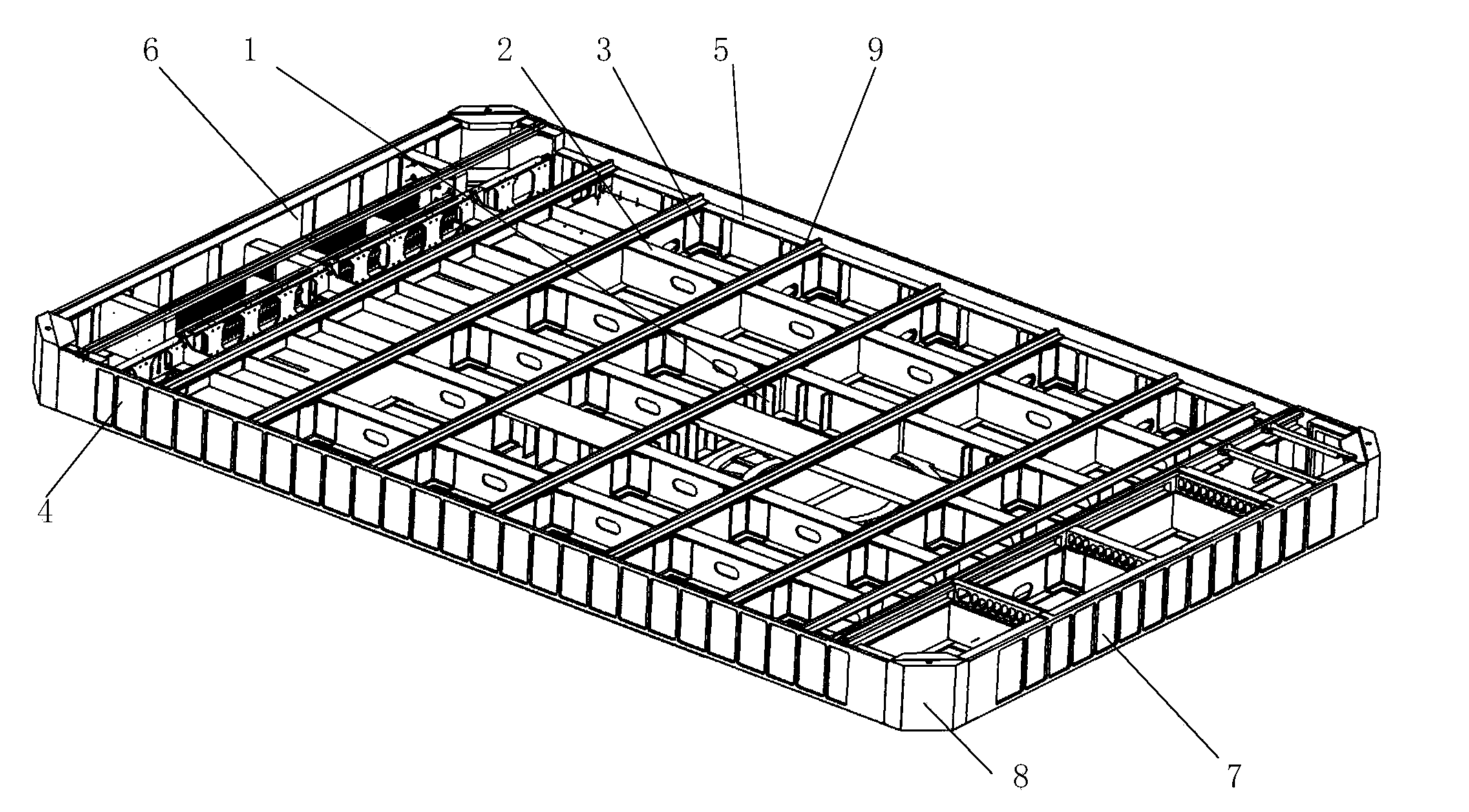

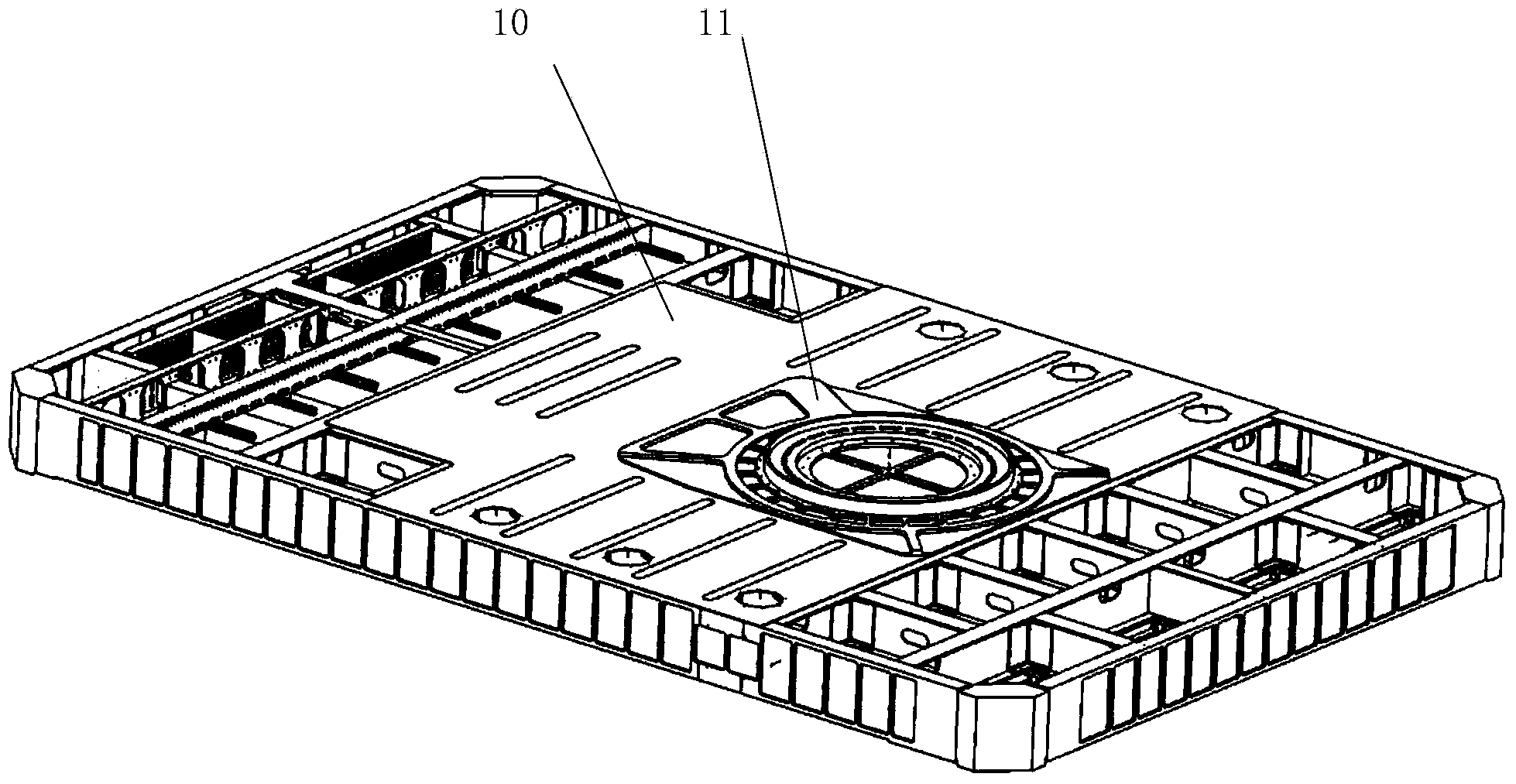

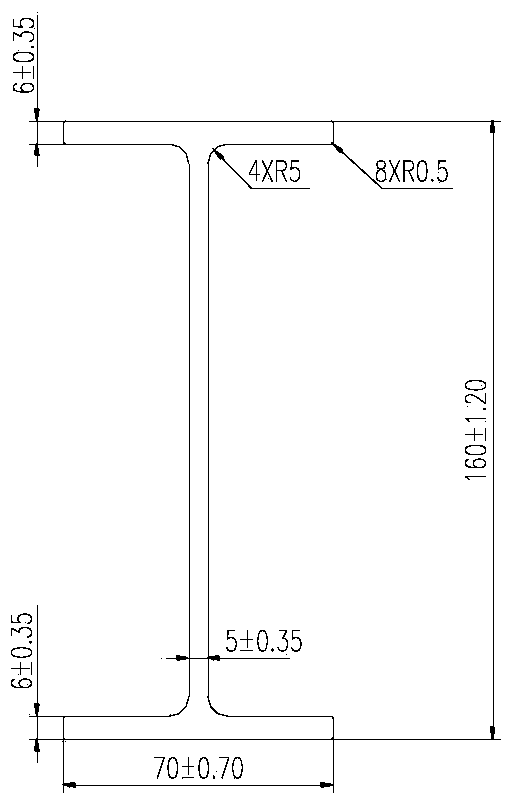

[0027] The structure of the embodiment includes casting frame 1, multiple new I-beams 2, connecting corner pieces 3, left longitudinal beam 4, right longitudinal beam 5, upper beam 6, lower beam 7, four-corner joint 8, waveguide support bar 9 , Skin 10, support plate 11; the middle and two lower sides of the two casting boxes are riveted with multiple I-beams 2 in the horizontal direction, and the middle of the horizontal I-beams passes through the connecting corner pieces 3 in the vertical direction. Riveted multiple I-shaped aluminum beams 2, left longitudinal beam 4, right longitudinal beam 5, upper beam 6, lower beam 7, through four corner joints 8 to form the frame of the frame, and at the same time by connecting corner pieces 3 and I-shaped aluminum beam 2 Riveted together; the waveguide support bar 9 is riveted on the front of the frame, the skin 10 is riveted on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com