A large phased array radar antenna frame structure and manufacturing method

A phased array radar, frame structure technology, applied in the direction of antenna support/installation device, etc., can solve the problems of unsuitable mass production, low precision, easy deformation, etc., and achieve the effect of improving environmental adaptability, high precision and rigidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

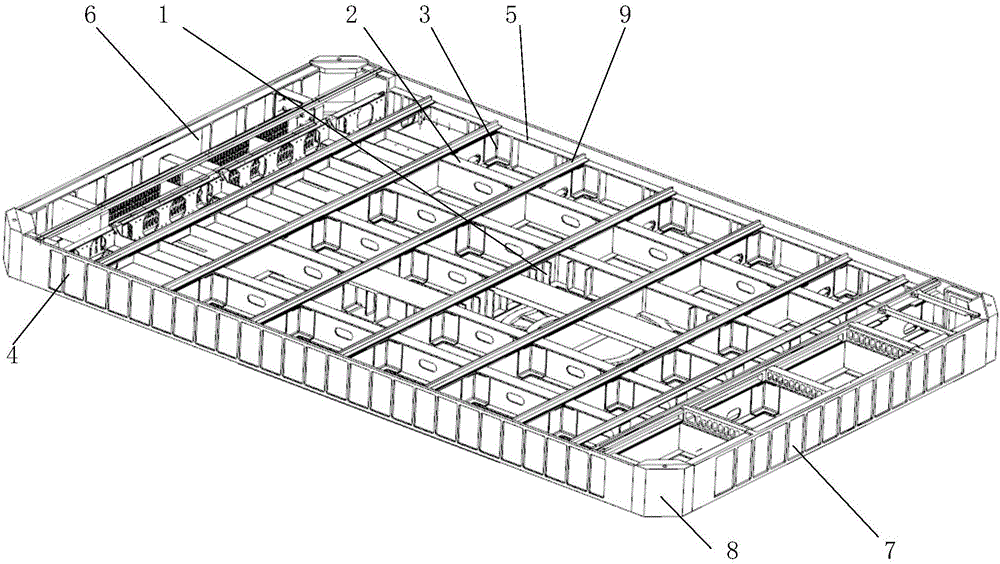

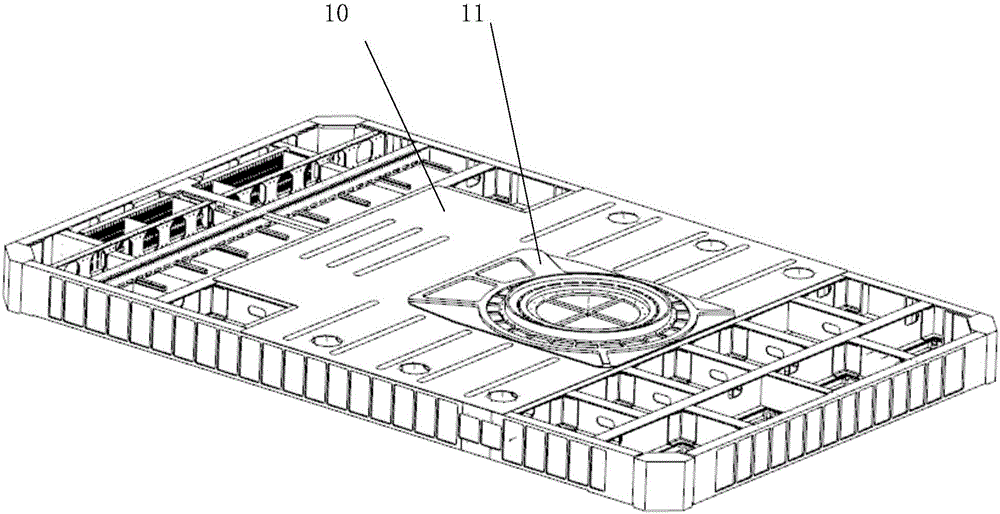

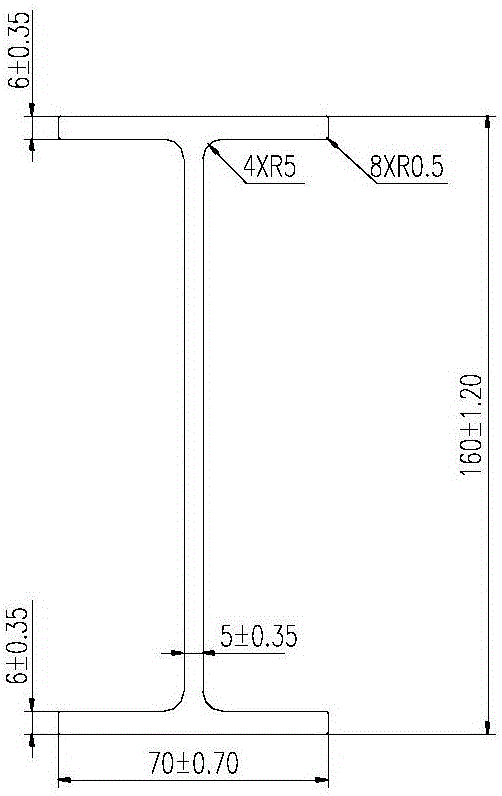

[0027] The structure of the embodiment includes a casting frame 1, a plurality of new I-shaped aluminum beams 2, connecting corner pieces 3, left longitudinal beams 4, right longitudinal beams 5, upper beams 6, lower beams 7, square joints 8, and waveguide support bars 9 , skin 10, support plate 11; the middle of the two casting boxes and the two lower and two sides are co-riveted with a plurality of I-shaped aluminum beams 2 along the horizontal direction, and the middle of the I-shaped aluminum beams in the horizontal direction is passed through the connecting corner piece 3 along the vertical direction Riveting multiple I-shaped aluminum beams 2, left longitudinal beam 4, right longitudinal beam 5, upper beam 6, and lower beam 7, forming the outer frame of the frame through four-corner joints 8, and connecting corner pieces 3 and I-shaped aluminum beams 2 rive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com