Novel wire clamping disc

A new type of clamping disc technology, applied in the field of new clamping discs, can solve the problems of uneven force on the two wires, small contact area, oxygen absorption corrosion, etc., and achieve the effects of reducing safety hazards, high safety, and avoiding breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

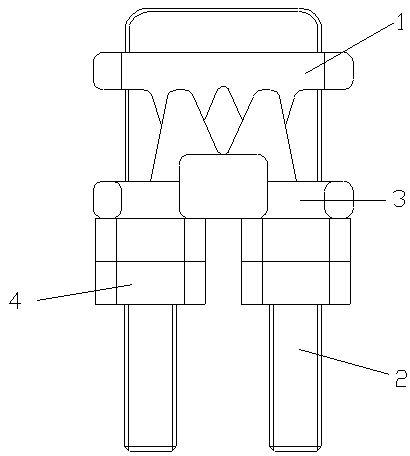

[0027] A new type of clamping disc according to the present invention, such as figure 1 As shown, it includes a U-shaped pressure ring 2 and a cover part 3 inserted from both ends of the U-shaped pressure ring 2, and the cover part 3 is preferably provided with the size of the two ends of the U-shaped pressure ring 2. Corresponding to the two through holes, the two ends of the U-shaped pressure ring 2 pass through the cover part 3 through the two through holes, and the end of the U-shaped pressure ring 2 is provided with a clamp to clamp the cover part 3, the clamping component 4 can move on the U-shaped pressure ring 2 to cooperate with the movement of the cover part 3, and the cover part 3 is provided with a clamping cable Draw-in slot, on the two side walls of the U-shaped pressure ring 2, a base 1 for supporting the cable is clamped, and the base 1 is provided with a groove for accommodating the cable, and the groove and the draw-in slot Cooperate to clamp the cable, and ...

Embodiment 2

[0029] On the basis of a new clamp disc described in Example 1, the end of the U-shaped pressure ring 2 is provided with threads, and the clamping part 4 is preferably a nut, and the nut is screwed on On the thread at the end of the U-shaped pressure ring 2, using a commonly used nut can effectively reduce the cost, which is a wider application of the present invention.

[0030] The base 1 is provided with locking slots for clamping the side walls of both sides of the U-shaped pressure ring 2, which can further fix the base 1 and the U-shaped pressure ring 2 to prevent the base 1 from being in the U-shaped The movement in the pressure ring 2 avoids the situation that the base 1 slips from the U-shaped pressure ring 2 in practical application, which increases the safety.

Embodiment 3

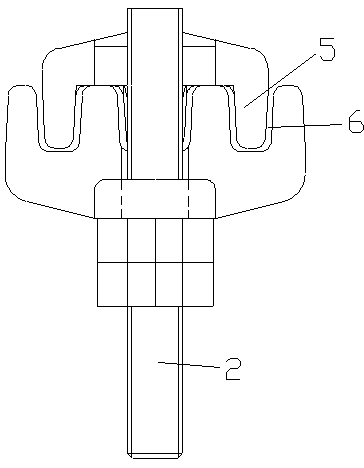

[0032] On the basis of a new type of clamping disc described in the above embodiments, as figure 2 As shown, the sidewalls on both sides of the card slot and the sidewalls on both sides of the groove have joint surfaces, and the joint surface is provided with a protruding part 5 and a concave part 6 that cooperate with each other, and the protruding part 5 It can be set on the cover part 3 or on the base 1, the recessed part 6 is set on the surface corresponding to the raised part 5, and the raised part 5 and the The setting of the recessed part 6 makes the cover part 3 and the base 1 have a claw-shaped structure; in the present invention, three protrusions 5 are preferably arranged on the side walls of the groove on both sides of the base 1, and the Three recessed parts 6 are provided on the two side walls of the card slot of the cover part 3, and the three raised parts 5 can be inserted into the three recessed parts 6 correspondingly, so that the base 1 and the cover The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com