System for driving electromagnetic appliance and motor driven vehicle

A technology for device driving and electric motors, which is applied in the control of motor vibration, electronic commutation motor control, motor vehicles, etc., and can solve problems such as difficulty in dealing with common mode noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach )

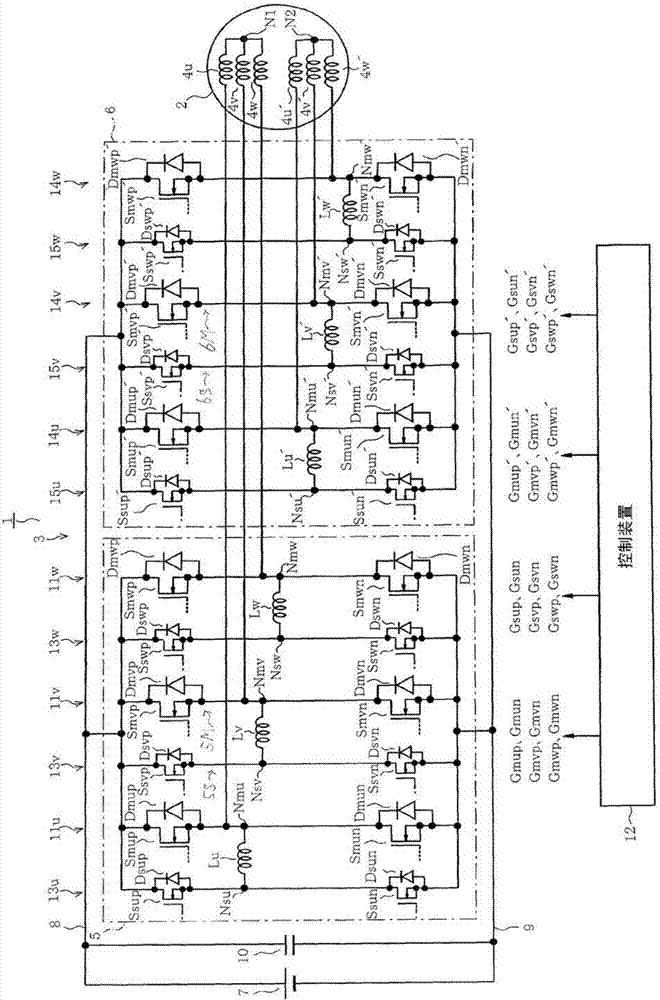

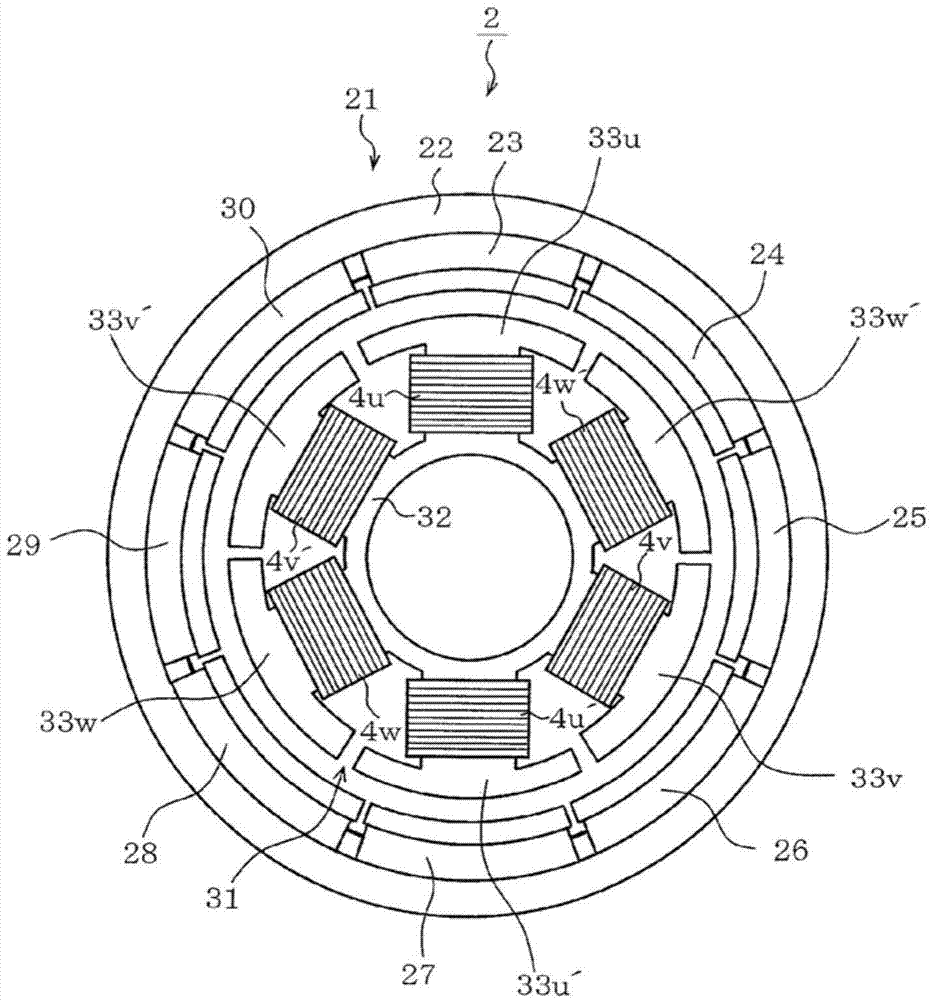

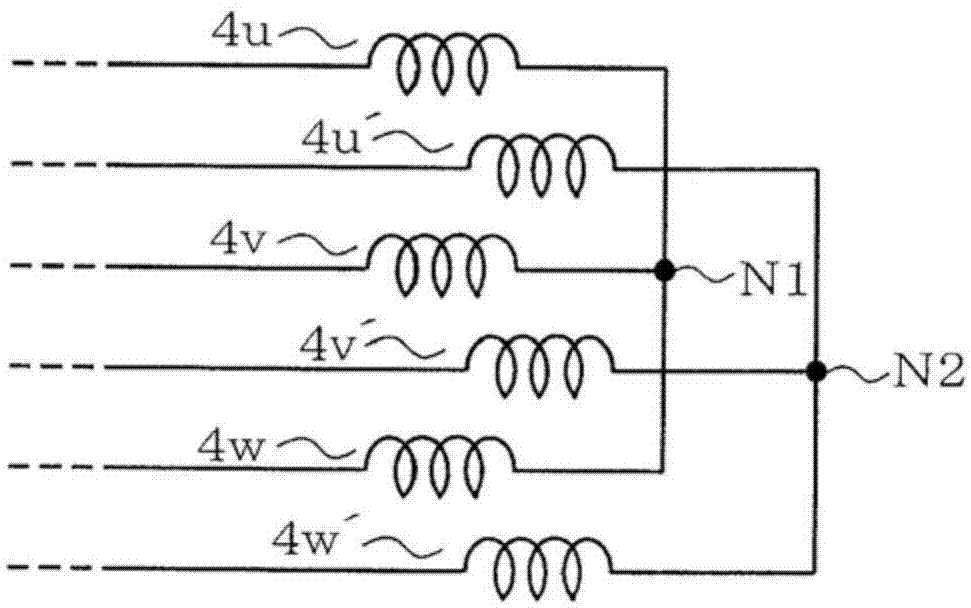

[0026] Below, refer to Figure 1 to Figure 12 , a first embodiment of a system for driving a motor as an electromagnetic device will be described. figure 1 The illustrated motor drive system 1 includes a motor 2 and a drive device 3 for driving the motor 2 . The motor 2 is, for example, a three-phase brushless DC motor, and includes first windings 4u, 4v, 4w and second windings 4u', 4v', 4w' as pairs of three-phase (n=3) stator windings. Details will be described later, but the winding structure of the motor 2 is such that the rotor rotates in the same direction when three-phase currents of opposite phases flow through the first windings 4u to 4w and the second windings 4u' to 4w'. Here, the motor 2 having the above structure is referred to as a "3-phase motor".

[0027] The drive device 3 includes a first power conversion device 5 and a second power conversion device 6 in parallel. Both the first power conversion device 5 and the second power conversion device 6 convert DC...

no. 2 Embodiment approach )

[0110] Figure 14 to Figure 17 In order to explain the drawings of the second embodiment, the same reference numerals are assigned to the same parts as those of the first embodiment, and description thereof will be omitted, and different parts will be described below. The driving device 51 constituting the transformer driving system 50 of the second embodiment includes a third power converting device 52 in addition to the first and second power converting devices 5 and 6 . The third power conversion device 52 is a DC-DC converter and includes a main half-bridge circuit 53 and an auxiliary half-bridge circuit 54 connected between the DC power supply lines 8 and 9 .

[0111] The main half-bridge circuit 53 is composed of a series circuit of main switching elements Smxp and Smxn, and the auxiliary half-bridge circuit 54 is composed of a series circuit of auxiliary switching elements Ssxp and Ssxn. Main freewheeling diodes Dmxp and Dmxn are respectively connected in antiparallel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com