Light-emitting diode driving method and operation method thereof

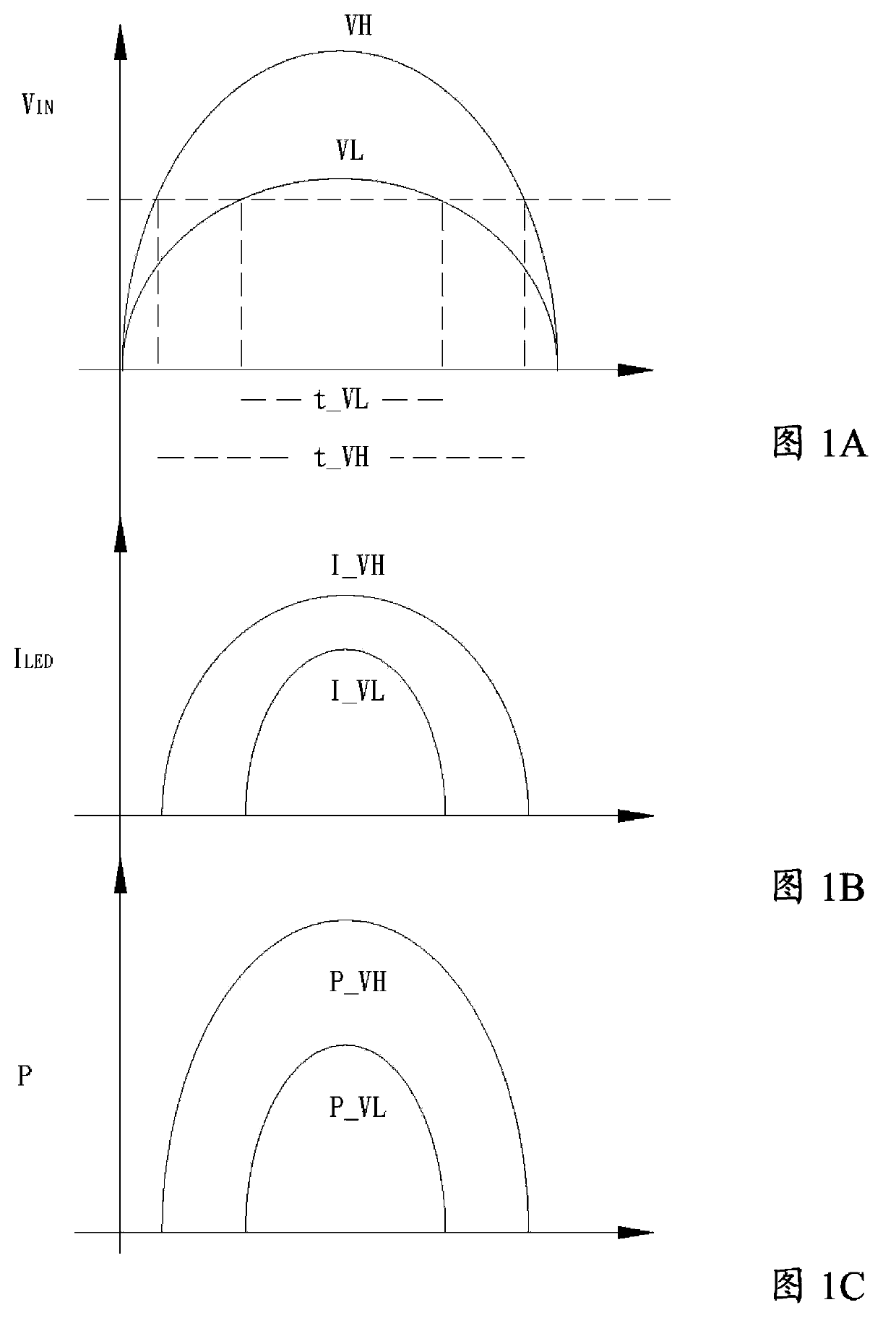

A light-emitting diode and driving device technology, which is applied in the field of light-emitting diode driving devices, can solve problems such as increased voltage and current, large power consumption, and overheating, so as to avoid excessive power consumption and overheating, and avoid average The effect of current inaccuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

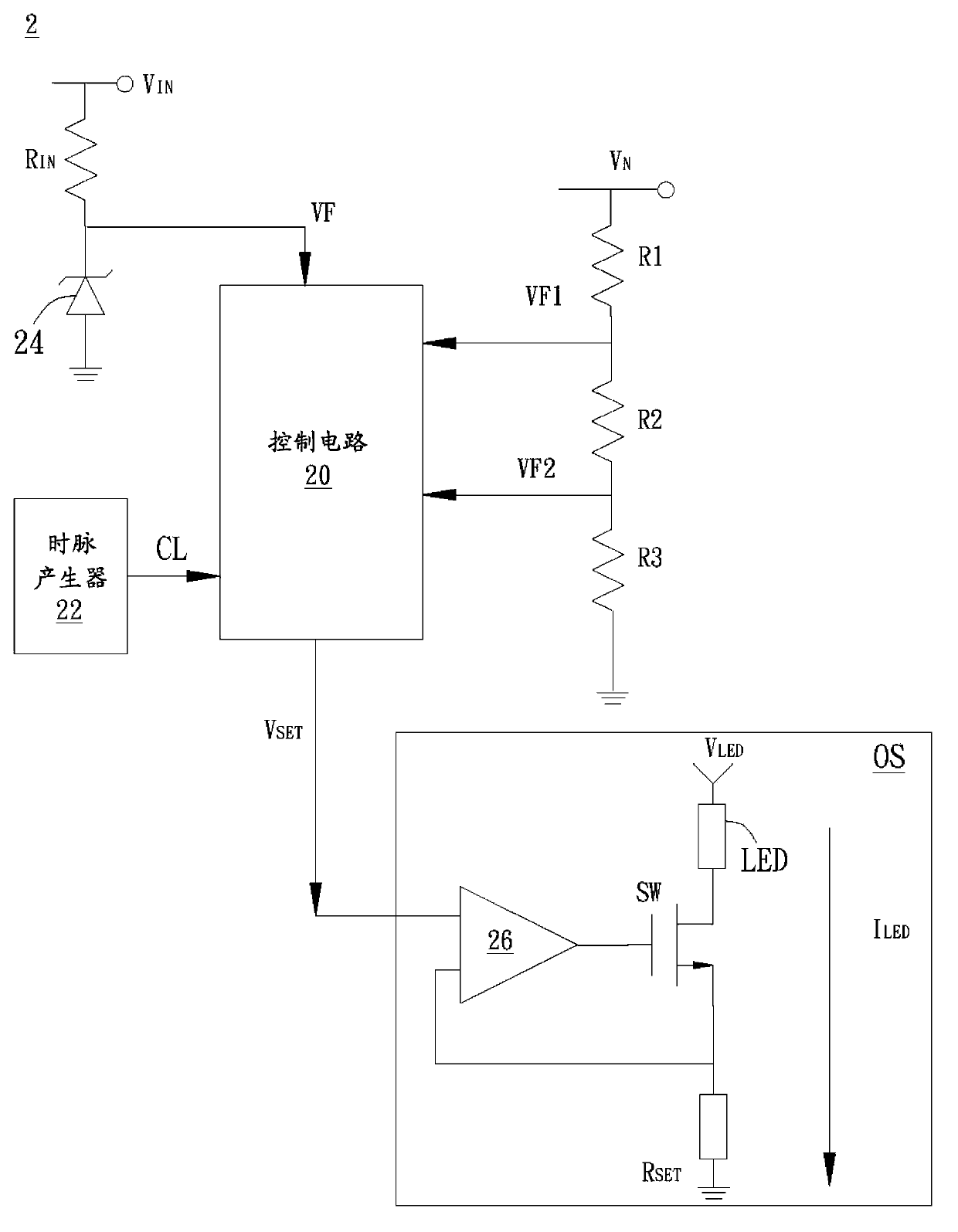

[0038] A specific embodiment according to the present invention is a light emitting diode driving device. In this embodiment, the LED driving device is used to drive the LED to emit light, but it is not limited thereto.

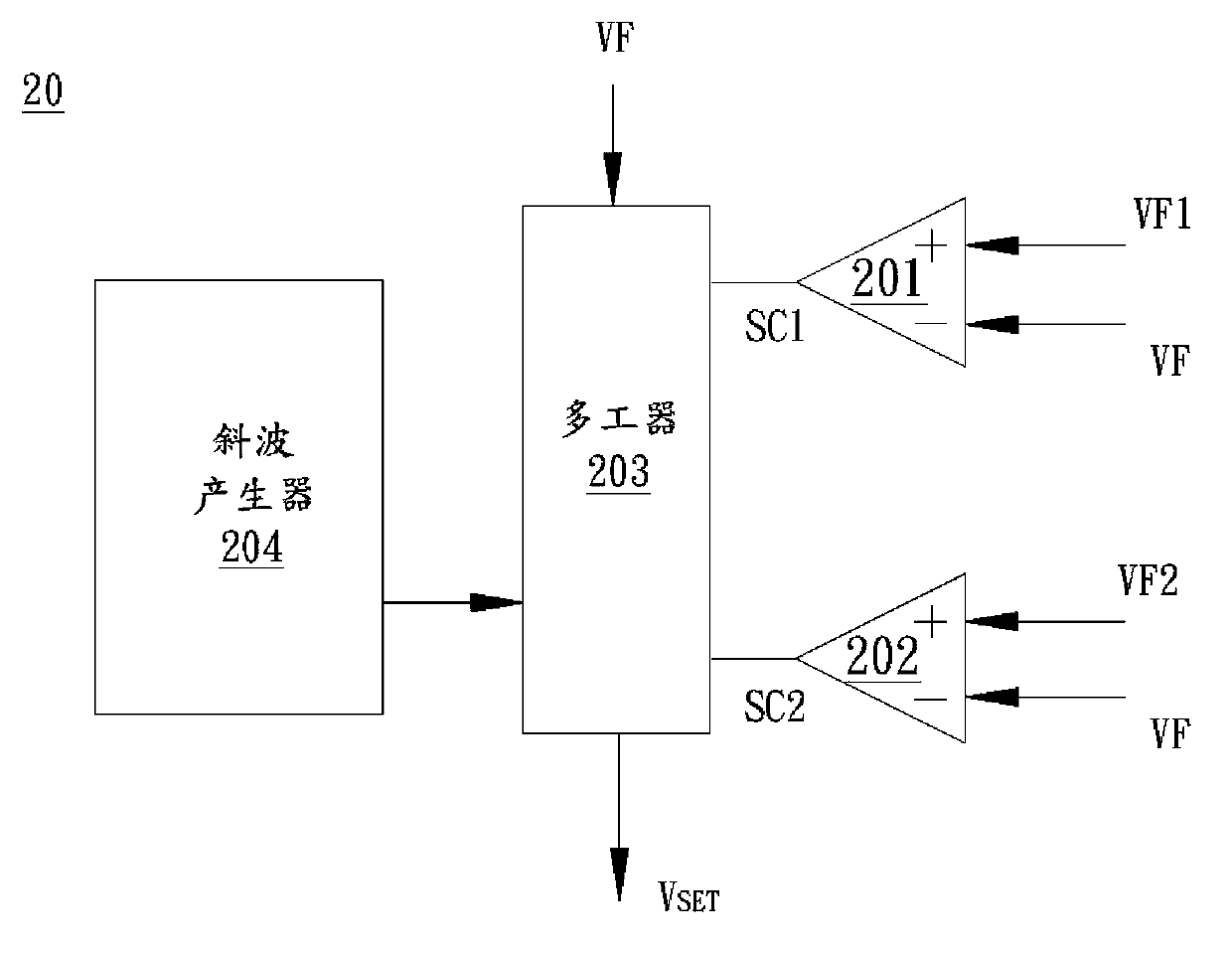

[0039] Please refer to figure 2 , figure 2 It is a schematic diagram illustrating the circuit structure of the light-emitting diode driving device of this embodiment. Such as figure 2 As shown, the light-emitting diode driving device 2 includes an output stage OS, an input resistor R IN , the control circuit 20, the clock generator 22, the regulator 24, the first voltage dividing resistor R connected in series with each other 1 , the second voltage divider resistor R 2 and the third voltage divider resistor R 3 .

[0040] Input resistance R IN One end of the coupling input voltage V IN , and the other end is coupled to the regulator 24 . The control circuit 20 is respectively coupled to the input resistor R IN and regulator 24, the first divider...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com