Method for drilling circuit board with high-precision and depth-controlled hole

A circuit board, high-precision technology, applied in the direction of electrical connection formation of printed components, etc., can solve the problems of uncontrolled, complex process control, unrealizable back drilling, etc., to eliminate differences in board thickness, ensure accuracy, and reduce distances. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

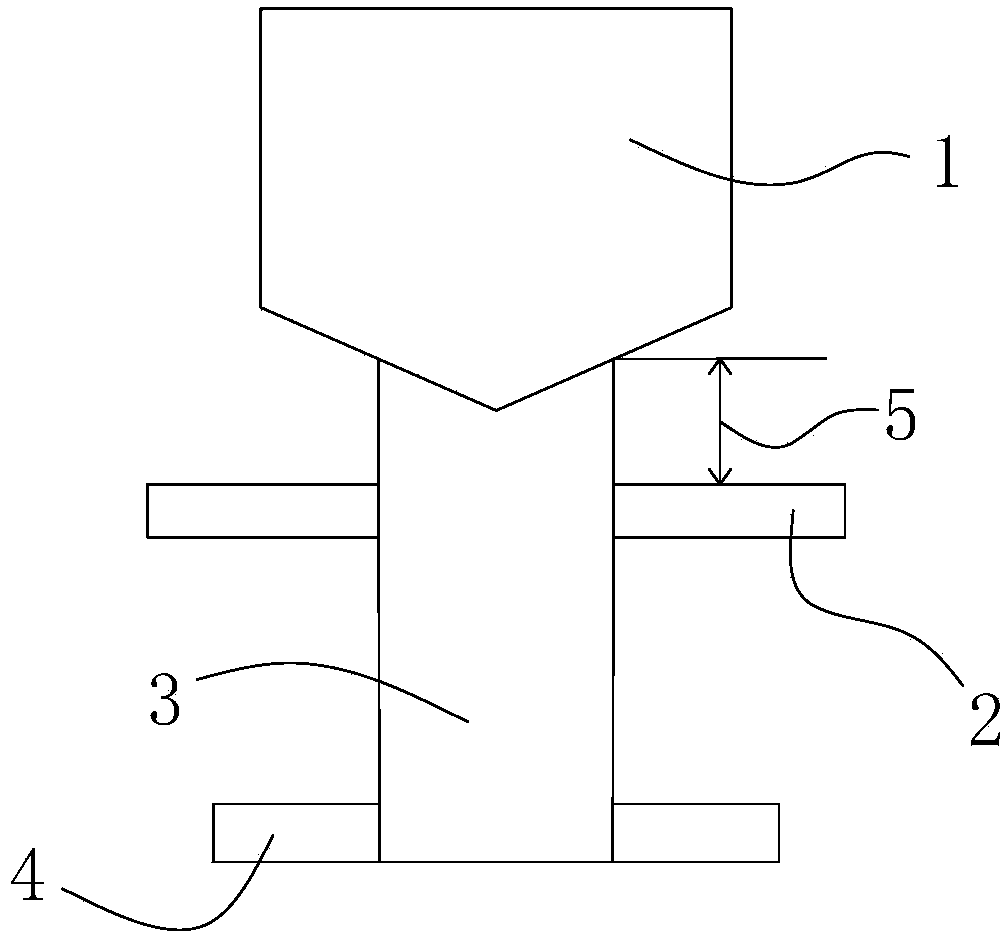

[0043] A method for high-precision depth-controlled drilling of circuit boards, including material cutting, inner-layer graphic production, etching, pressing, drilling, conductive hole production, conductive hole metallization, rimming, controlled-depth drilling, and outer-layer graphic production , surface treatment process; where:

[0044] Cutting, inner layer graphic making, pressing, outer layer graphic making, and surface treatment are carried out in accordance with conventional processes.

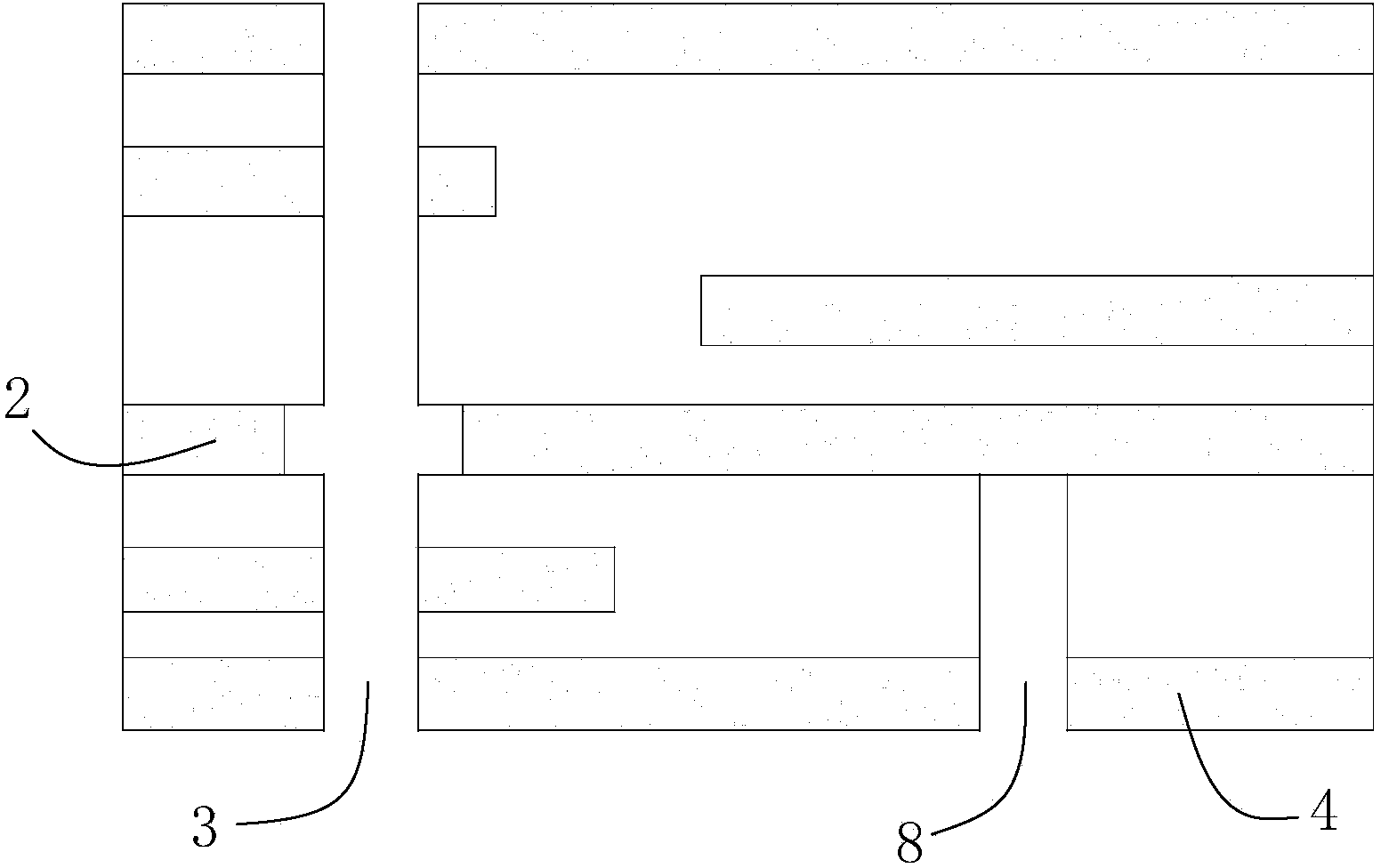

[0045] In the etching process, the positioning layer 7 is etched according to the predetermined design. In this embodiment, since the aperture of the depth control drill is designed to be 0.35mm, the conductive material at the wall of the hole drilled in the drilling process will be placed in the positioning layer. Etched away, the diameter of the etched area is 0.1mm larger than the aperture of the hole drilled in the drilling process; the positioning layer is insulated from the hole...

Embodiment 2

[0059] The method of the circuit board high-precision depth control drilling of this embodiment is basically the same as the method in embodiment 1, the difference is:

[0060] In the etching process, since the aperture of the depth control drill is designed to be 0.4 mm, the conductive material at the wall of the hole drilled in the positioning layer is etched away, and the diameter of the etching area is smaller than that of the hole drilled in the drilling process. The hole diameter is 0.1mm larger.

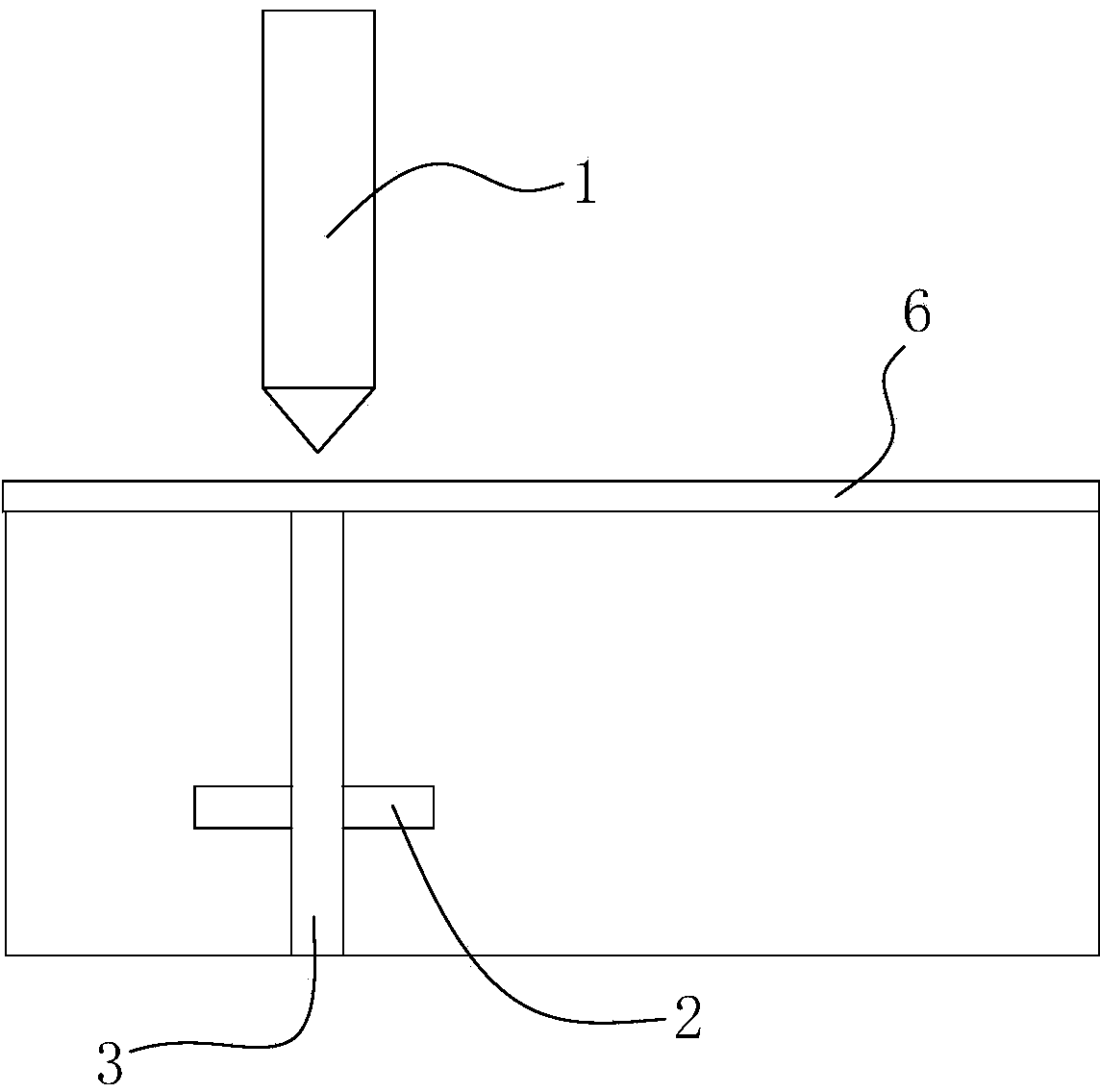

[0061] In the conductive hole metallization process, the conductive hole 8 and the through hole 3 drilled in the drilling process are metallized at the same time. Since the thickness-to-diameter ratio of the conductive hole is 1.2:1, copper (silver) paste is used to fill the hole. Metallize the inner wall of the conductive hole, make the positioning layer 7 conduct with the bottom surface 4 of the circuit board through the conductive hole 8, and insulate the through hole 3 fro...

Embodiment 3

[0065] The method of the circuit board high-precision depth control drilling of this embodiment is basically the same as the method in embodiment 1, the difference is:

[0066] In the etching process, since the aperture of the depth control drill is designed to be 0.45mm, the conductive material at the wall of the hole drilled in the positioning layer is etched away, and the diameter of the etched area is smaller than that of the hole drilled in the drilling process. The hole diameter is 0.15mm larger.

[0067] In the drilling process, the hole is drilled at the position where the depth needs to be controlled, and the drilling depth is to drill through the positioning layer to perform a high-precision depth-controlled blind hole process;

[0068] In the conductive hole manufacturing process, the conductive hole is drilled in the edge area of the circuit board by using the method of deep-controlled drilling to process the blind hole.

[0069] In the conductive hole metalliza...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com