Automatic dipping machine

A dipping machine, automatic technology, applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problems of uneven thickness of glue hanging, increased labor costs, etc., to improve the pass rate, high production efficiency, and stable operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

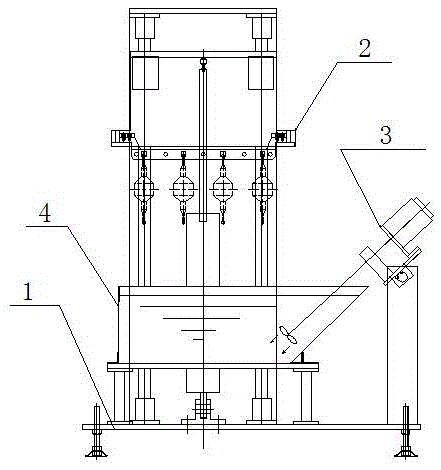

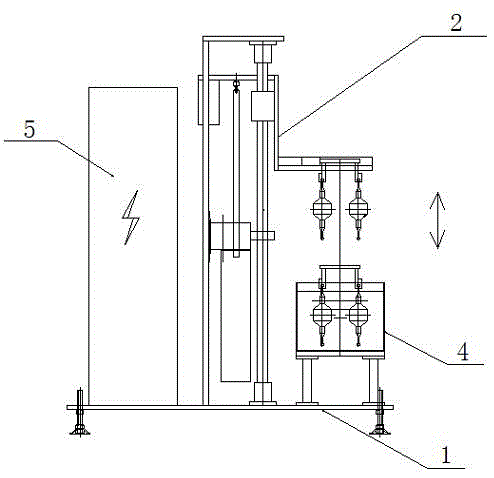

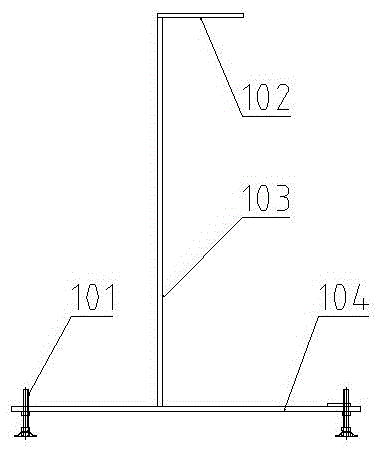

[0020] like Figure 1 to Figure 6 As shown, the automatic dipping machine includes a mechanical main body 1, a lifting mechanism 2, a stirring mechanism 3, a glue tank 4 and an electric control box 5, and the lifting mechanism 2, the stirring mechanism 3, the glue tank 4 and the electric control box 5 are respectively fixed by bolts On the mechanical main body 1, the mechanical main body 1 includes a foot cup 101, a top plate 102, a vertical plate 103, and a seat plate 104. The top plate 102 is provided with a bolt hole of a shaft sleeve 201, and is welded with the vertical plate 103, and the seat plate 104 is provided with a shaft. The bolt hole of cover 201, and weld with vertical plate 103, be provided with foot cup 101 under seat plate 104, lifting mechanism 2 comprises axle sleeve 201, sliding bearing 202, sliding shaft 203, counterweight 204, fast positioning 205, speed regulation Lifting motor 206, hinge shaft 207, hinge seat 208 and lifting frame 209, axle sleeve 201 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com