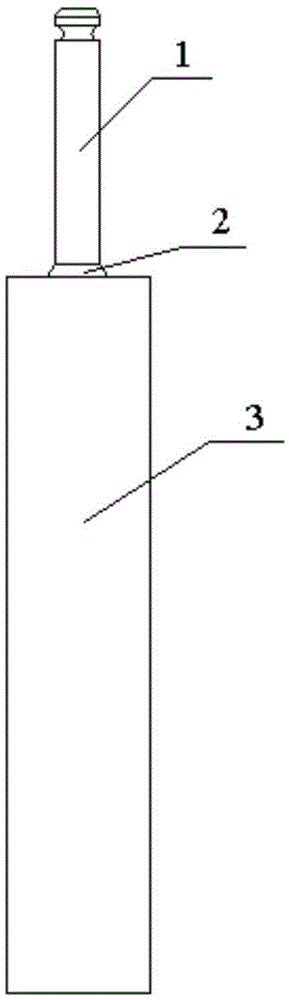

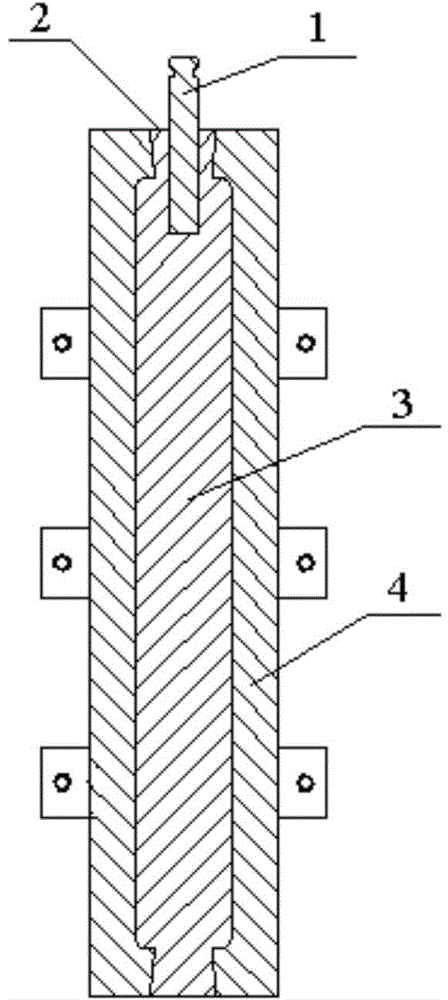

A rapid fusion welding method of consumable electrode and dummy electrode of electroslag remelting furnace

An electroslag remelting furnace and consumable electrode technology, which is applied in the field of consumable electrode preparation technology, can solve the problems of cumbersome processes of consumable electrodes and dummy electrodes, hidden dangers in production and safety, and many materials and labor, etc. End shrinkage, easy control, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A rapid fusion welding method for a consumable electrode and a dummy electrode of an electroslag remelting furnace, comprising the following steps:

[0022] (1) Make a dummy electrode for standby, which is made of 304 stainless steel;

[0023] (2) According to the total length of the consumable electrode and the dummy electrode must be within the stroke of the material rod, determine the length of the dummy electrode inserted below the liquid surface of the ingot mold steel, and mark it; and place the dummy electrode at 400°C Bake for half an hour or more;

[0024] (3) The self-consumable electrode is poured by mold casting. When the molten steel is poured to 300mm from the upper opening of the ingot mold, slowly insert the above dummy electrode vertically downward at the center of the upper opening of the ingot mold. The insertion depth of the dummy electrode is For the length marked in step (2), fine-tune the concentricity of the dummy electrode and the ingot mold; a...

Embodiment 2

[0028] A rapid fusion welding method for a consumable electrode and a dummy electrode of an electroslag remelting furnace, comprising the following steps:

[0029] (1) Make a dummy electrode for standby, which is made of 304 stainless steel;

[0030] (2) According to the total length of the consumable electrode and the dummy electrode must be within the stroke of the material bar, the lower part of the consumable electrode is 20mm away from the bottom of the crystallizer of the electroslag remelting furnace, and it is determined that the dummy electrode is inserted below the liquid surface of the ingot mold steel Mark the length; and bake the dummy electrode at 600°C for more than half an hour;

[0031] (3) Pouring the self-consumable electrode by die casting. When the molten steel is poured to 200mm from the upper opening of the ingot mold, slowly insert the above dummy electrode vertically downward at the center of the upper opening of the ingot mold. The insertion depth of ...

Embodiment 3

[0035] (1) Make a dummy electrode for standby, which is made of 316 stainless steel;

[0036] (2) According to the fact that the total length of the consumable electrode and the dummy electrode must be within the stroke of the material rod, and the lower part of the consumable electrode is 30mm away from the bottom of the crystallizer of the electroslag remelting furnace, it is determined that the dummy electrode is inserted below the liquid surface of the ingot mold steel Mark the length; and bake the dummy electrode at 400°C for more than half an hour;

[0037] (3) The self-consumable electrode is poured by mold casting. When the molten steel is poured to 400mm from the upper opening of the ingot mold, slowly insert the above dummy electrode vertically downward at the center of the upper opening of the ingot mold. The insertion depth of the dummy electrode is For the length marked in step (2), fine-tune the concentricity of the dummy electrode and the ingot mold; at the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com