A non-contact wheel diameter dynamic measuring device and its measuring method

A dynamic measurement and non-contact technology, applied in the field of optical measurement, can solve problems such as small operating space, low measurement accuracy, and complex structure of the measurement system, and achieve the effects of improved response speed, simple data processing, and simple measurement principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The preferred embodiments will be described in detail below in conjunction with the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

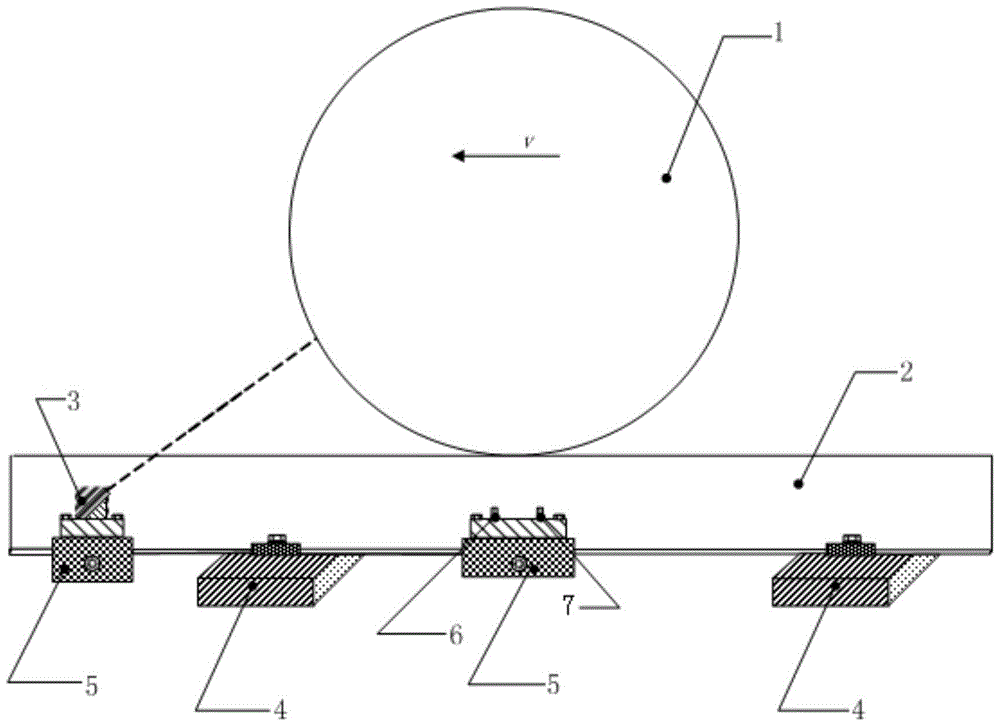

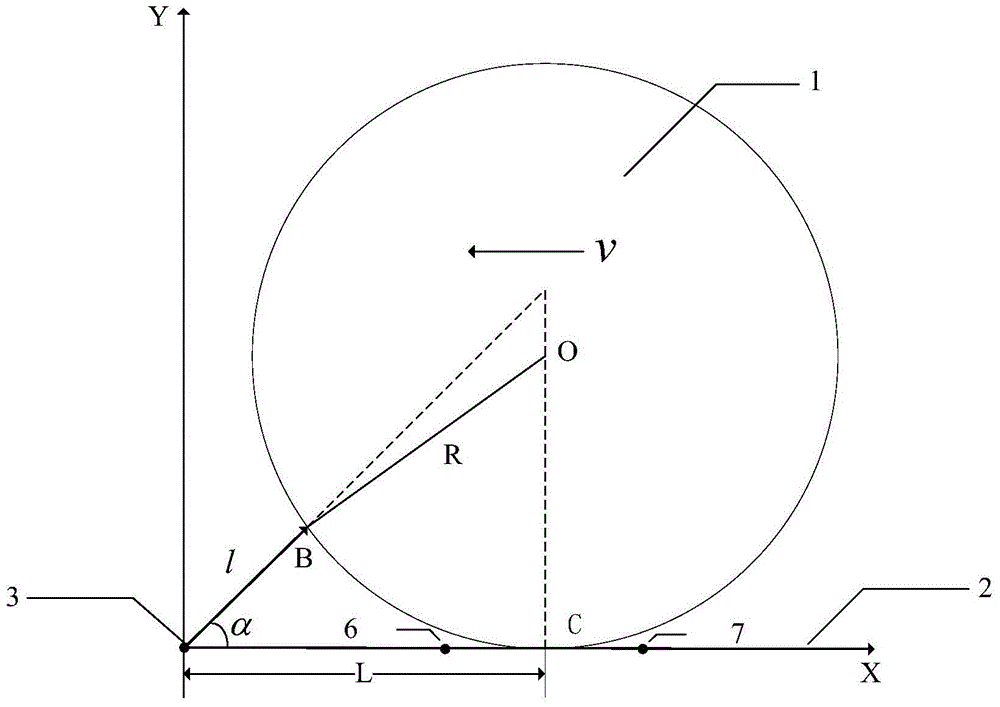

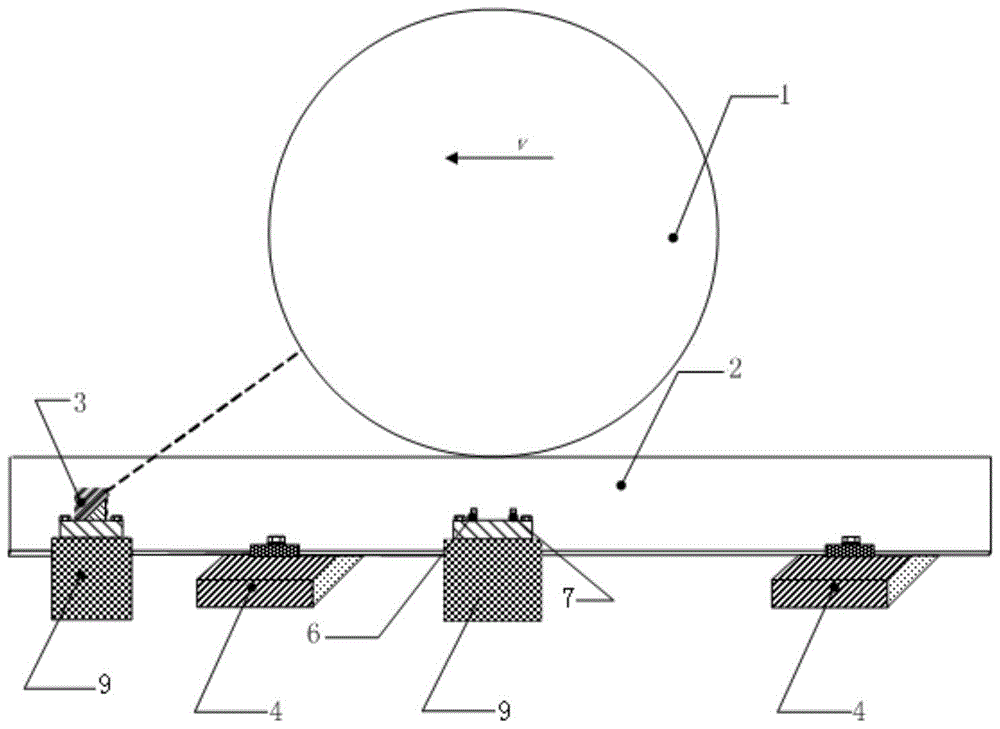

[0039] figure 1 It is the first embodiment of the non-contact dynamic measurement device for wheel diameter using a single laser displacement sensor. like figure 1 As shown, this embodiment is a wheel diameter non-contact dynamic measuring device using a single laser displacement sensor, specifically comprising: a laser displacement sensor 3, a first eddy current sensor 6, a second eddy current sensor 7 and a central processing unit 8 (not shown in the figure marked). The laser displacement sensor 3 , the first eddy current sensor 6 and the second vehicle eddy current sensor 7 are all fixed on the rail 2 through the block 5 or directly by bonding, and are located on the outside (or inside) of the rail 2 at the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com