Treatment method for nitric-acid-containing wastewater in adipic acid production technology

A production process and treatment method technology, applied in the field of adipic acid production process wastewater treatment, can solve the problems of secondary pollution, high cost of nitric acid sludge, unsuitable for industrial wastewater treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

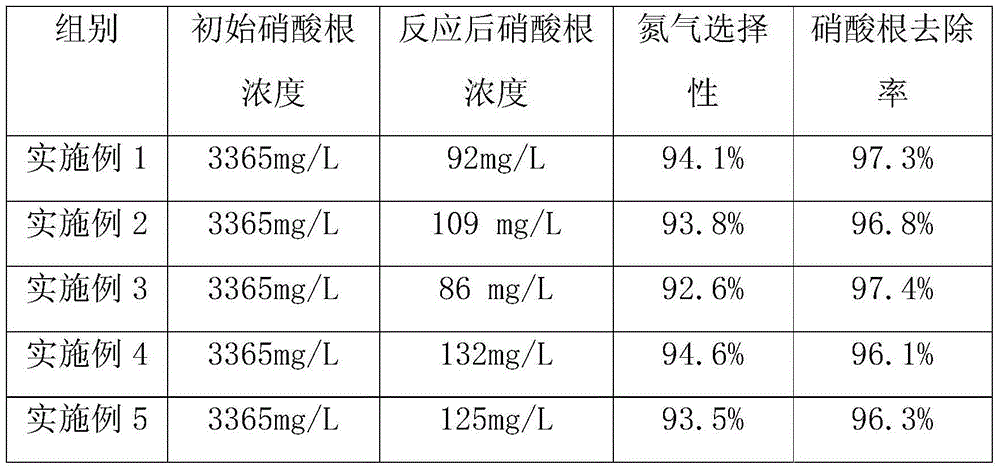

Embodiment 1

[0023] First, pre-treat the iron filings: soak them in methanol for 10 minutes, and then soak them in 0.05mol / L sulfuric acid solution for 10 minutes for subsequent use.

[0024] Put 1L of adipic acid production wastewater with an initial nitrate concentration of 3365mg / L into the reaction vessel, add 16.825g of pretreated iron filings and 6.73g of urea, and soak for 4 hours at 50°C. After the reaction, the nitrate concentration is 92mg / L, the selectivity of nitrogen is 94.1%.

Embodiment 2

[0026] First, pre-treat the iron shavings: soak them in ethanol for 10 minutes, and then soak them in 0.5mol / L hydrochloric acid solution for 30 minutes for subsequent use.

[0027] Put 1L of adipic acid production wastewater with an initial nitrate concentration of 3365mg / L into the reaction vessel, add 16.825g of pretreated iron shavings and 6.73g of urea, and soak for 6 hours at 20°C. After the reaction, the nitrate concentration is 109mg / L, the selectivity of nitrogen is 93.8%.

Embodiment 3

[0029] First, pre-treat the copper shavings: soak them in methanol for 10 minutes, and then soak them in 0.05mol / L hydrochloric acid solution for 15 minutes for subsequent use.

[0030] Put 1L of adipic acid production wastewater with an initial nitrate concentration of 3365mg / L into the reaction vessel, add 100.95g of pretreated copper filings and 33.65g of urea, and soak for 10 hours at 30°C. After the reaction, the nitrate concentration is 86mg / L, the selectivity of nitrogen is 92.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com