Anti-seepage treatment method for artificial dam

A technology of anti-seepage membrane and earth-rock dam, which is applied in water conservancy projects, marine engineering, construction, etc., can solve the problems of short service life and high construction cost of dam anti-seepage, and achieve long service life, short construction period and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

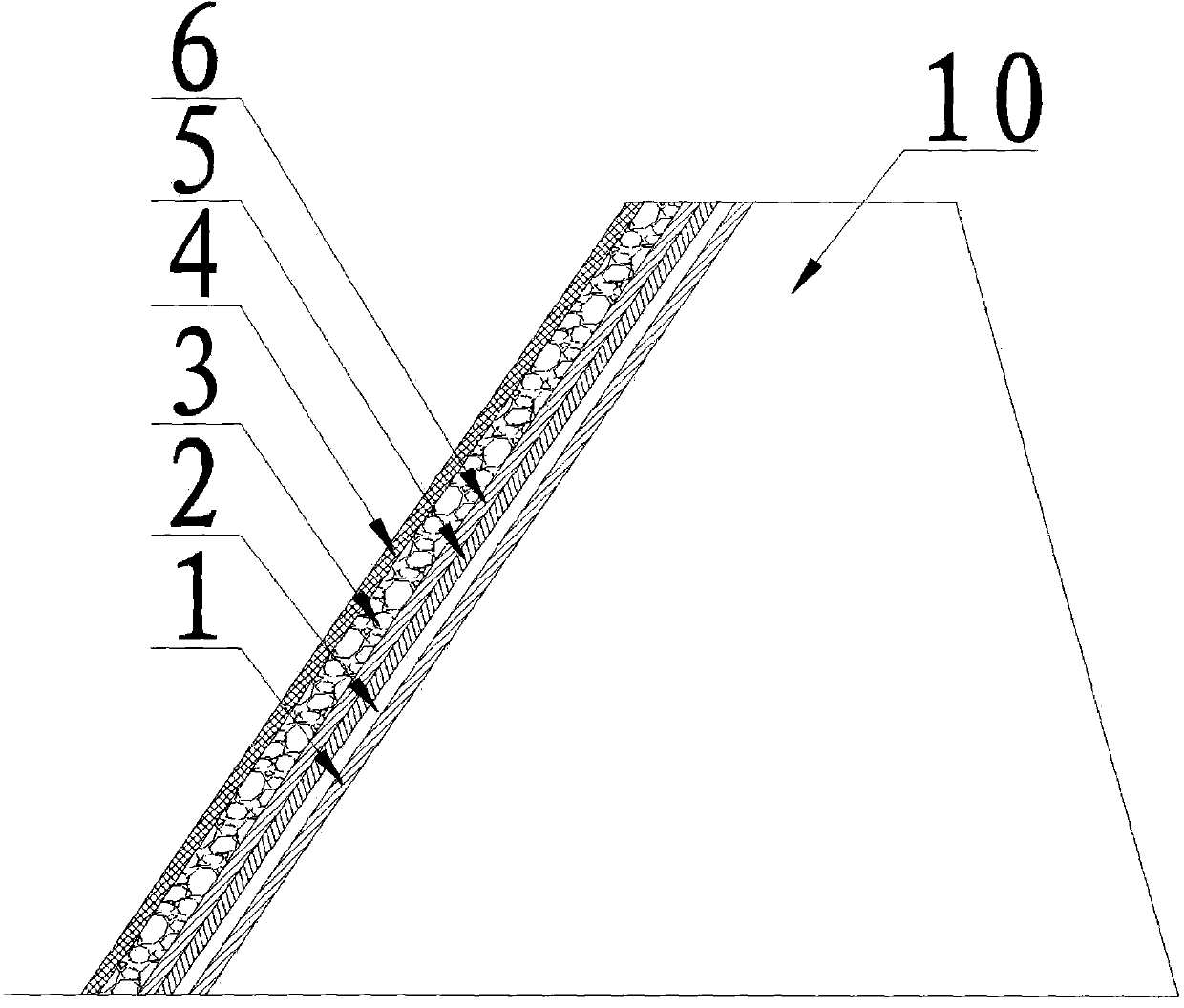

[0022] For further elaborating the technical means and effect that the present invention takes for reaching the intended invention purpose, below in conjunction with accompanying drawing and preferred embodiment, to the specific implementation mode, solid structure of a kind of earth-rock dam anti-seepage structure that proposes according to the present invention The structure, characteristics and functions thereof are described in detail below. In the following description, different "an embodiment" or "an embodiment" do not necessarily refer to the same embodiment. Furthermore, the particular features, structures, or characteristics of one or more embodiments may be combined in any suitable manner.

[0023] An anti-seepage structure of an earth-rock dam, which is arranged on the side of the earth-rock dam body 10, including: an underbed layer 1 arranged in sequence from top to top, which is made of 5-10 cm thick sieved silt and fine particles Composed of sandy clay; anti-se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com