Louvers with functions of self-cleaning and filtering

A shutter and self-cleaning technology, applied in the field of shutters, can solve the problems of increasing factory manufacturing costs, increasing engineering investment and operating costs, and achieve the effects of reducing labor intensity, saving investment and operating costs, and being easy to combine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

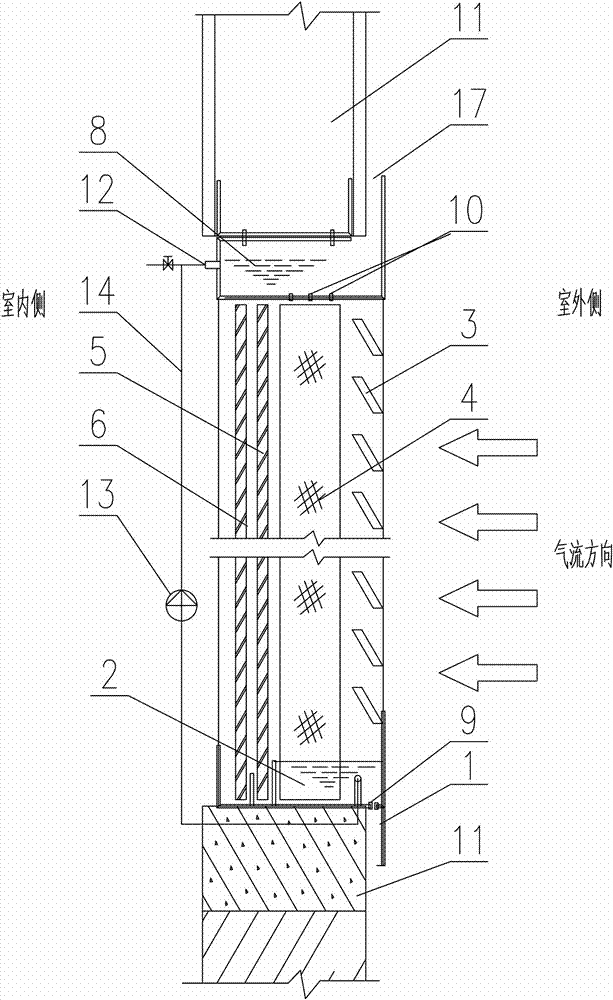

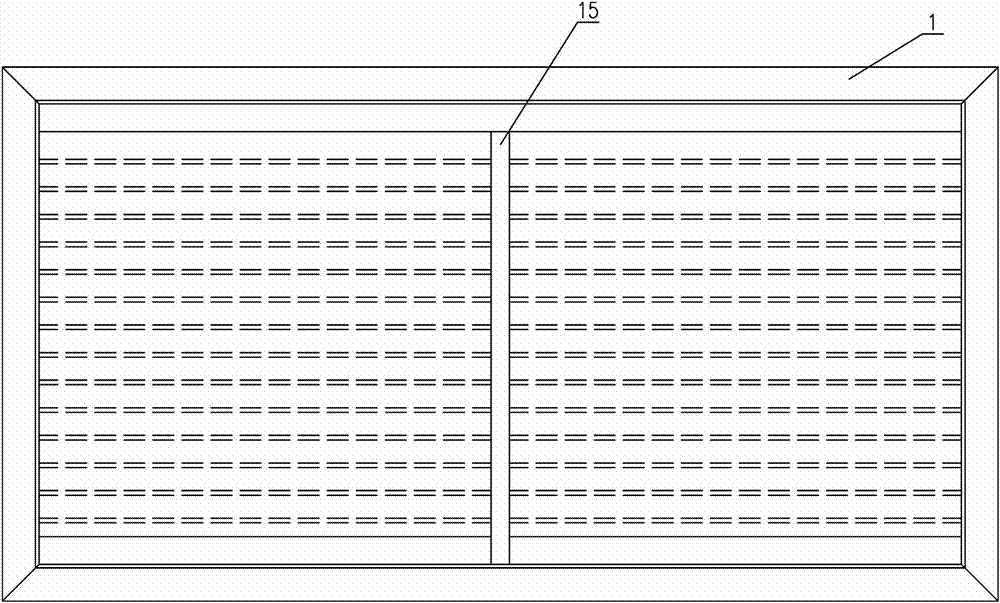

[0020] Such as figure 1 Among them, a self-cleaning louver with filter includes the louver installed on the outer wall 11. The structure of the louver is that a fixed rain-proof louver 3 is arranged in the outer frame 1 of the louver. The material of the louver can be: plastic, carbon steel, stainless steel, fiberglass , aluminum alloy, etc.

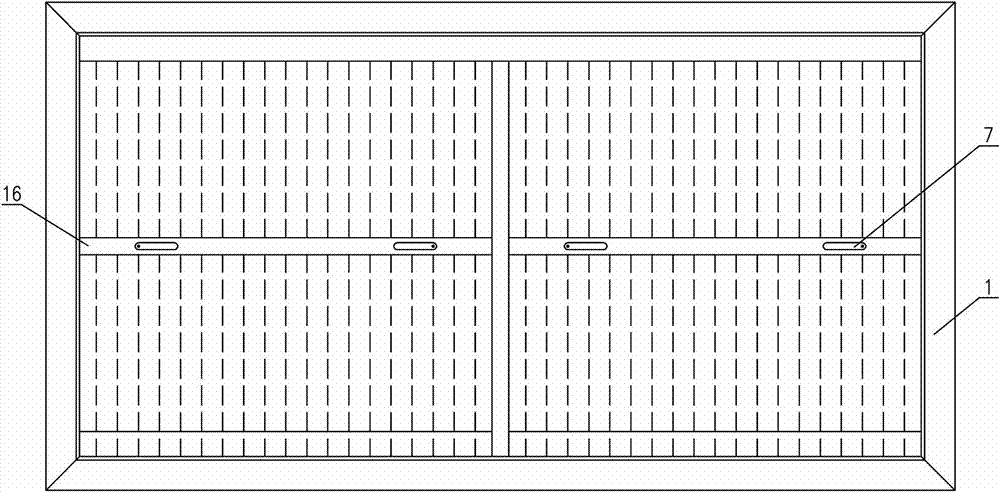

[0021] One side of the louver is provided with a filter screen and a frame 4. In this example, a stainless steel filter screen is preferably used. The stainless steel filter screen is installed on the frame, and then the whole is installed in the outer wall 11. In this example, the filter screen and the frame 4 are installed on the louvers. indoor side.

[0022] An upper water tank 8 is arranged above the filter screen and the skeleton 4, and the bottom of the upper water tank 8 is provided with a plurality of upper water tank shower holes 10. Rainwater inlet 17, the installed rainwater inlet 17 has a certain distance from the wall of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com