A parallel flow heat exchanger

A parallel flow heat exchanger, a pair of technology, applied in the direction of heat exchanger shell, indirect heat exchanger, heat exchanger type, etc., can solve the problem of difficulty in reducing production cost, easy to produce waste, affecting the heat exchange efficiency of working fluid, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

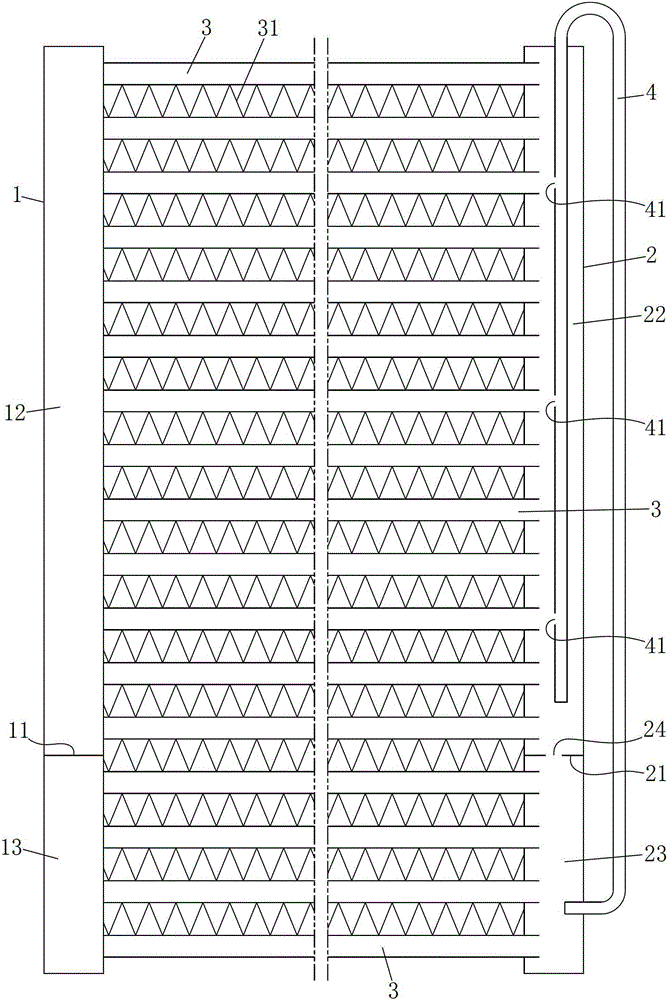

[0011] Example: see figure 1 , the present invention includes a pair of left and right headers that are parallel to each other and separated from each other and several flat tubes whose two ends are respectively communicated with the inner chambers of the left and right headers and are parallel to each other. Fins are arranged between adjacent flat tubes, wherein the left collector There is a left partition in the manifold to separate the left manifold into the upper chamber of the left manifold and the lower chamber of the left manifold, and a right partition is arranged in the right manifold to divide the right manifold into the right manifold The upper chamber and the lower chamber of the right collector, the upper chamber of the right collector and the lower chamber of the right collector are connected through the through hole on the right partition, the upper chamber of the left collector and the right collector The height of the upper chamber is equal, the height of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com