Method and system for controlling sintering end point

A technology of sintering end point and control method, which is applied to furnace types, furnaces, lighting and heating equipment, etc., can solve the problems of inability to guarantee the quality of sintered ore, and the sintering end point cannot be in a preset position, and achieves a fast control response speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

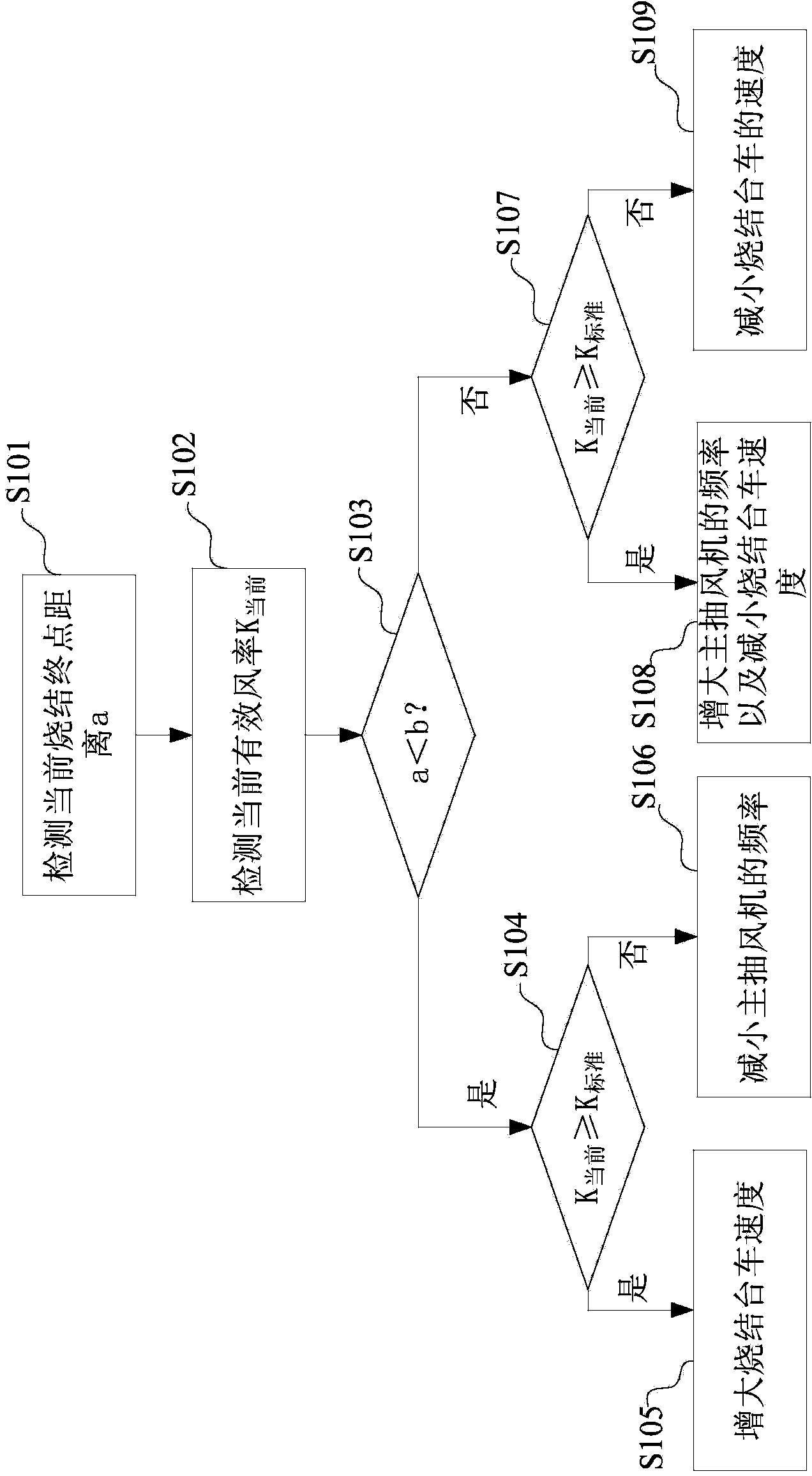

[0057] Please refer to the attached figure 2 , figure 2 The flowchart of the method for controlling the sintering end point provided by Embodiment 1 of the present invention is shown.

[0058] figure 2 The process shown includes:

[0059] S101. Detect the distance a of the current sintering end point.

[0060] During the sintering production process, there is a certain thickness of sintered material on the sintering trolley, and the sintering material is sintered with the operation of the sintering trolley. Sintering end point. The distance from the sintering end point refers to the distance between the sintering end point and the initial position where the sintering material starts to sinter (usually a fixed position, such as the position of the feed port of the sintering trolley). Usually, in order to ensure the quality of sintering ore, different types of sintering materials have their own preset sintering end distance b, but in the actual sintering production proce...

Embodiment 2

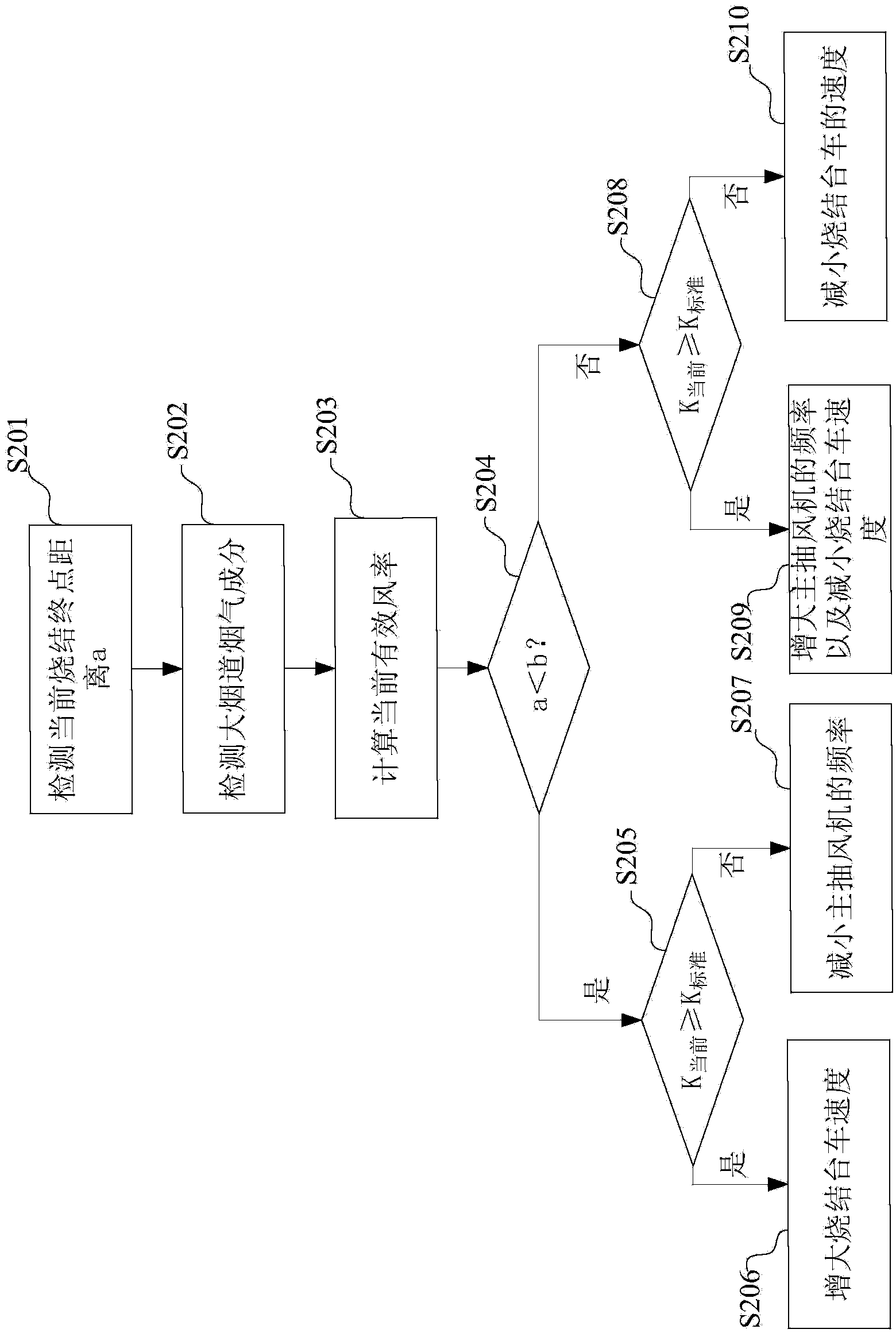

[0108] As described in Example 1, the current effective wind rate can also be obtained by detecting the smoke composition of the large flue, please refer to the attached image 3 , image 3 The flowchart of the method for controlling the sintering end point provided by the second embodiment of the present invention is shown.

[0109] image 3 The process shown includes:

[0110] S202. Detect the smoke components of the large flue.

[0111] Step S202 usually uses a flue gas analyzer to detect the flue gas components after participating in the reaction. Of course, the flue gas composition of the large flue can be detected directly in the large flue, or can be calculated by detecting the flue gas composition of each bellows of the sintering system. The preferred scheme adopts the following technical scheme to detect the smoke components of the large flue:

[0112] a. Detect the flue gas composition of each bellows of the sintering system;

[0113] b. The average value of th...

Embodiment 3

[0126] Please refer to the attached Figure 4 , Figure 4 A specific process of adjusting the frequency of the main exhaust fan provided by Embodiment 3 of the present invention is shown.

[0127] Figure 4 The process shown includes:

[0128] S301. Establish a correspondence table between the absolute value of the difference between the standard effective wind rate and the current effective wind rate and the frequency adjustment amplitude of the main exhaust fan, where the absolute value is proportional to the frequency adjustment amplitude.

[0129] S302. Adjust the frequency of the main exhaust fan according to the corresponding table.

[0130] The adjustment in this step includes two operations of increasing and decreasing. Reduce the frequency of the main exhaust fan with step S106 in embodiment one, specifically can be adjusted as follows:

[0131] when , the frequency of the main exhaust fan is reduced by 1hz per minute.

[0132] when , the frequency of the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com