Device for measuring electrostatic adsorption force and desorption time of electrostatic chuck

An electrostatic chuck and measuring device technology, which is applied in the direction of measuring devices, force/torque/work measuring instruments, and testing of mechanical components, can solve problems such as low precision and inability to apply plasma environments, and achieve high measurement accuracy and structure Simple, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

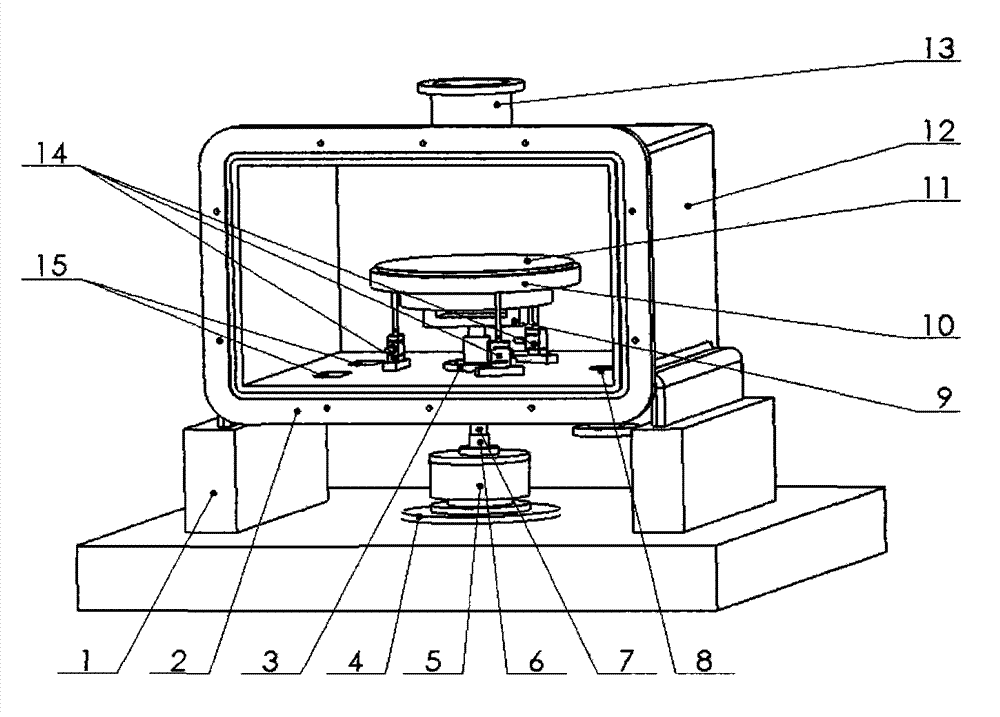

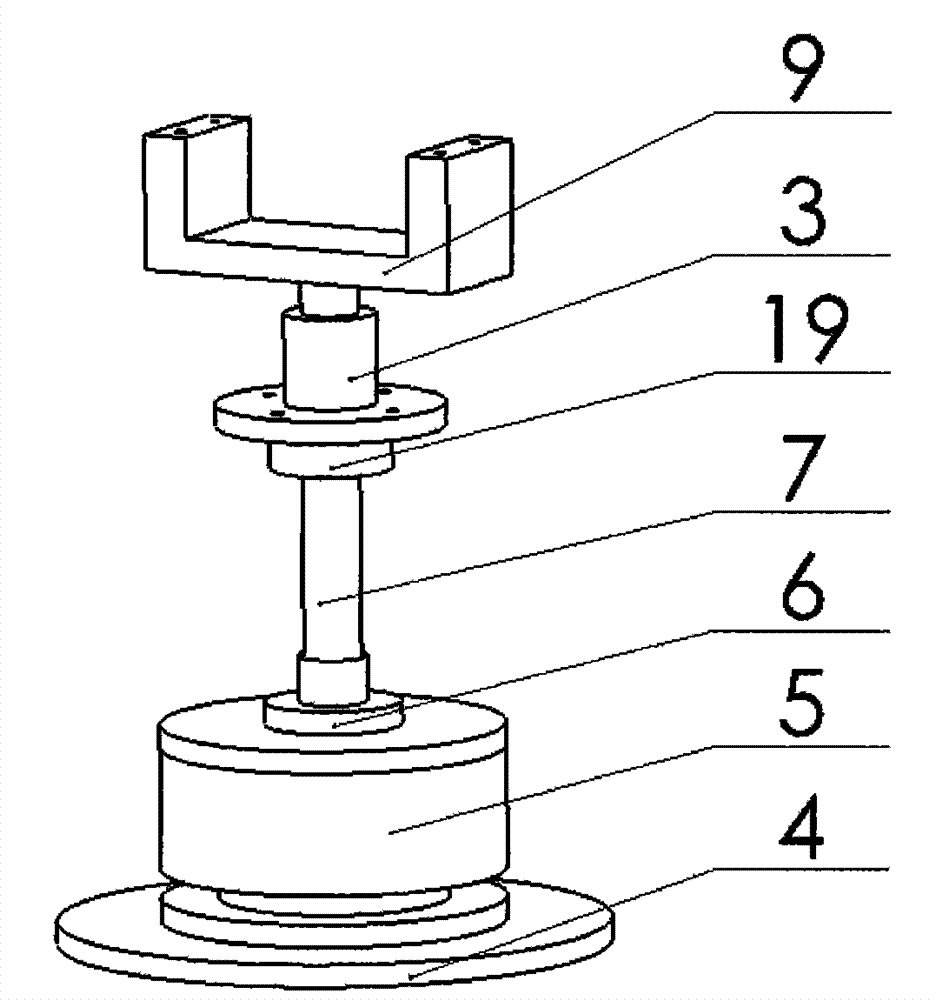

[0046] Electrostatic chuck electrostatic adsorption force and desorption time measurement device, including:

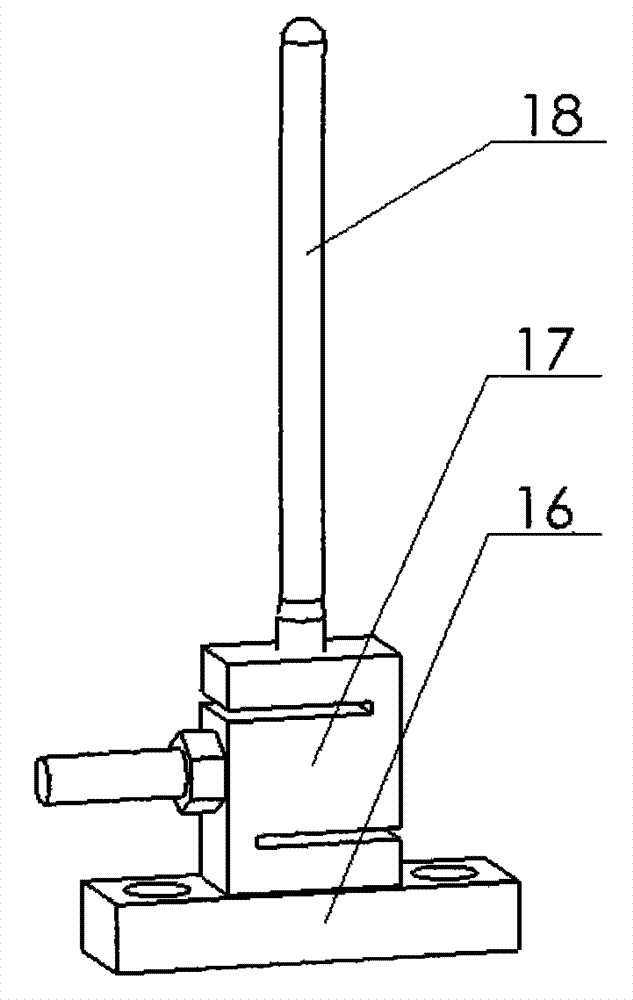

[0047]A vacuum chamber; the vacuum chamber includes a chamber housing 12, an observation window 2, a function reserved port and a vacuum acquisition device; the measurement data obtained by the measuring device is transmitted through the function reserved port on the vacuum chamber 12 The vacuum acquisition device includes a dry pump and a molecular pump, the dry pump and the molecular pump are connected in parallel, and are connected to the vacuum chamber 12 through a pipeline; the function reserved port includes a data transmission port 15, a plasma input port 13 And the air extraction hole 8; the data transmission port 15 is located at the bottom of the chamber, and the pressure sensor 17 data output line is connected with the data acquisition system outside the chamber through the data transmission port 15, wherein the data transmission port 15 is sealed by a stati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com