Online detection method for pyrolysis gas-phase components of tobacco additive or tobacco material

A technology for gas phase components and additives, applied in the field of gas phase component determination, can solve the problems of long measurement time, low efficiency, poor accuracy, etc., and achieve the effect of saving time and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

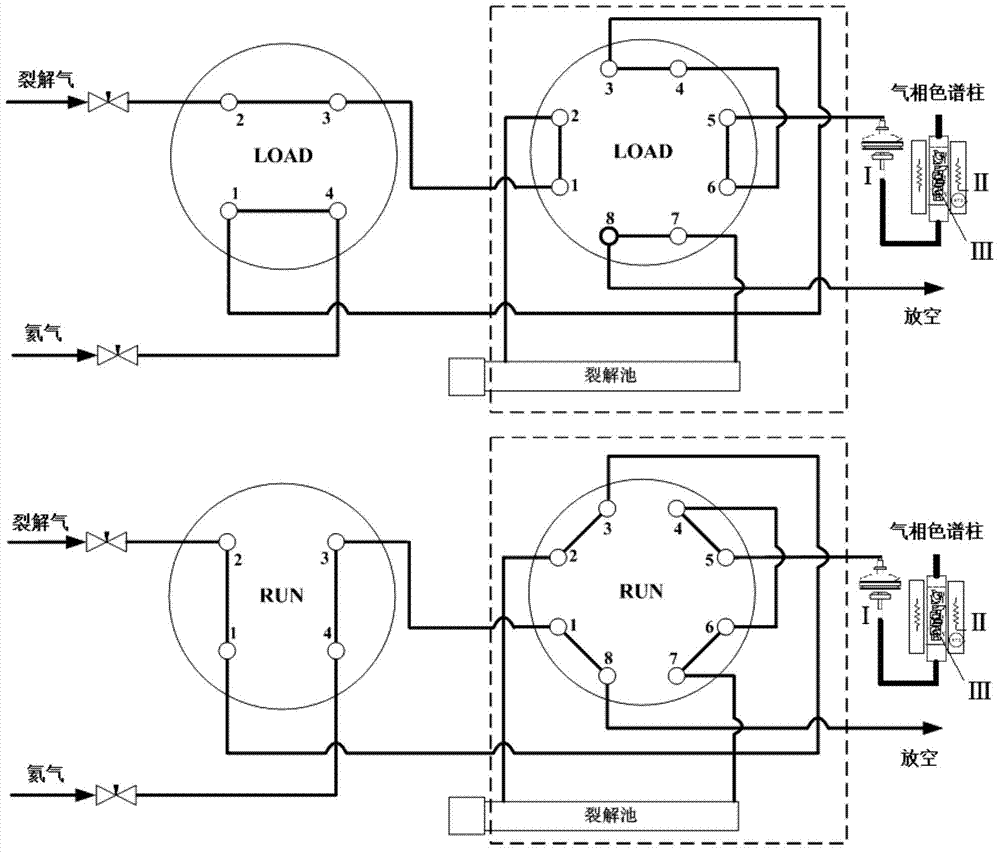

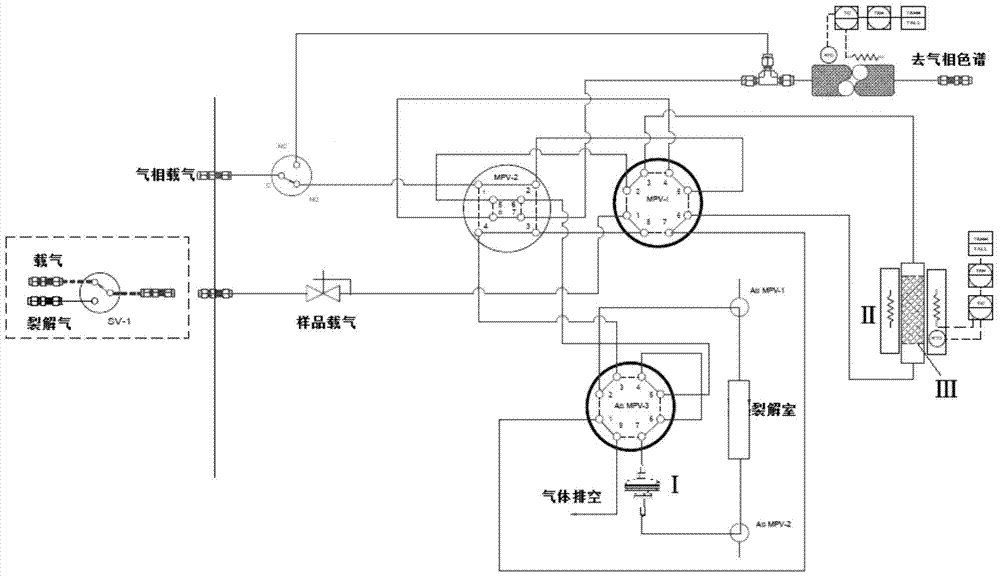

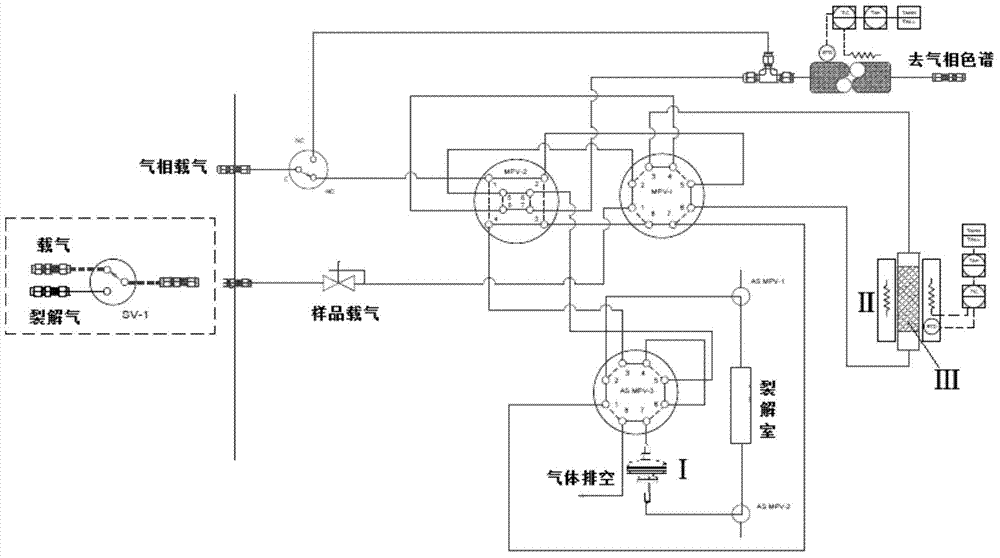

Method used

Image

Examples

Embodiment 1

[0058] 1 method

[0059] 1.1 Cracking: first fill the middle part of the pyrolysis quartz tube with quartz wool, then weigh 1±0.05mg of tobacco leaf powder, put it on the quartz wool, then plug the upper end of the sample with quartz wool, and then put it into the CDS 2000 pyrolysis instrument. Under the oxygen-containing gas atmosphere, the platinum wire is heated to carry out the staged temperature programmed cracking; the cracking conditions of the CDS 2000 cracking instrument are: cracking gas: 10% O 2 and 90%N 2 Mixed gas; gas flow rate: 276ml / min; cracking chamber temperature: 250°C; heating rate: the initial temperature is 300°C, hold for 5s, then raise the temperature to 900°C at 30°C / s, and hold for 5s.

[0060] 1.2 Filtration: The components produced by the cracking are filtered online through the Cambridge filter device connected to the cracking instrument, and the diameter of the Cambridge filter is 1cm;

[0061] 1.3 Trapping and sampling: the filtered gas phase ...

Embodiment 2

[0074] 1 method

[0075] 1.1 Cracking: Put a quartz rod in the pyrolysis quartz tube first, and fill the upper end of the quartz rod with about 1mg of quartz wool, compact it, weigh 1±0.05mg of sucrose on the quartz wool, and then fill the upper end of the sample with About 1 mg of quartz wool is then put into a CDS 5250T pyrolysis instrument, and under an oxygen-containing gas atmosphere, the platinum wire is heated to carry out stage-by-stage temperature programmed pyrolysis; the cracking conditions of the CDS 5250T pyrolysis instrument are: pyrolysis gas: 10% O 2 and 90%N 2 Mixed gas; gas flow rate: 70ml / min; cracking chamber temperature: 300°C; heating rate: the initial temperature is 300°C, keep for 5s, then raise the temperature to 900°C at 30°C / s, and keep for 5s.

[0076] 1.2 Filtration: The components produced by the cracking are filtered online through the Cambridge filter device connected to the cracking instrument, and the diameter of the Cambridge filter is 1cm; ...

Embodiment 3

[0088] 1 method

[0089] 1.1 Pyrolysis: first fill the middle part of the pyrolysis quartz tube with quartz wool, then weigh 1±0.05mg of cigarette paper, put it on the quartz wool, then plug the upper end of the cigarette paper with quartz wool, and then put it into the CDS 2000 pyrolysis instrument , in an oxygen-containing gas atmosphere, the platinum wire is heated for stage-by-stage temperature-programmed pyrolysis. The cracking conditions of the CDS 2000 cracking instrument are: cracking gas: 10%O 2 and 90%N 2 Mixed gas; gas flow rate: 276ml / min; cracking chamber temperature: 250°C; heating rate: the initial temperature is 300°C, hold for 5s, then raise the temperature to 900°C at 30°C / s, and hold for 5s.

[0090] 1.2 Filtration: The components produced by the cracking are filtered online through the Cambridge filter device connected to the cracking instrument, and the diameter of the Cambridge filter is 1cm;

[0091] 1.3 Trapping and sampling: The filtered gas phase c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ionization potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com