Method for controlling pressure switch through pressure predictor

A predictor and pressure technology, applied in the direction of electric fluid pressure control, etc., can solve the problem of inability to accurately control the given pressure, achieve the effect of improving accuracy and avoiding time delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

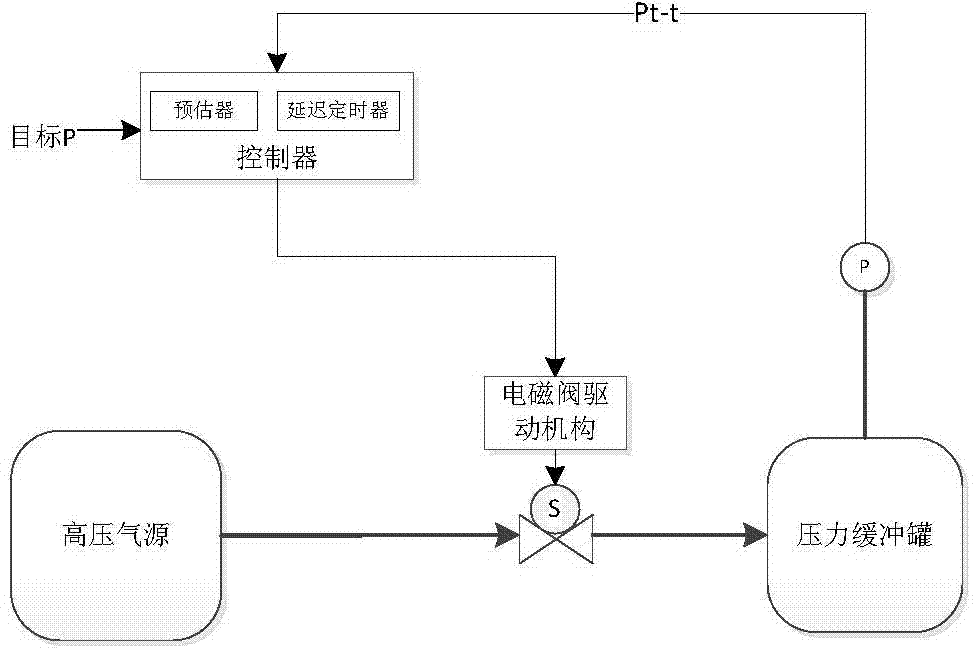

[0023] A method for controlling a pressure switch by a pressure estimator, which is applied to a pressure control system including a high-pressure gas source, a solenoid valve, a solenoid valve drive mechanism, a pressure buffer tank, a pressure gauge and a controller, and the pressure estimator is set in the controller and delay timers such as figure 1 As shown, the method specifically includes the following steps:

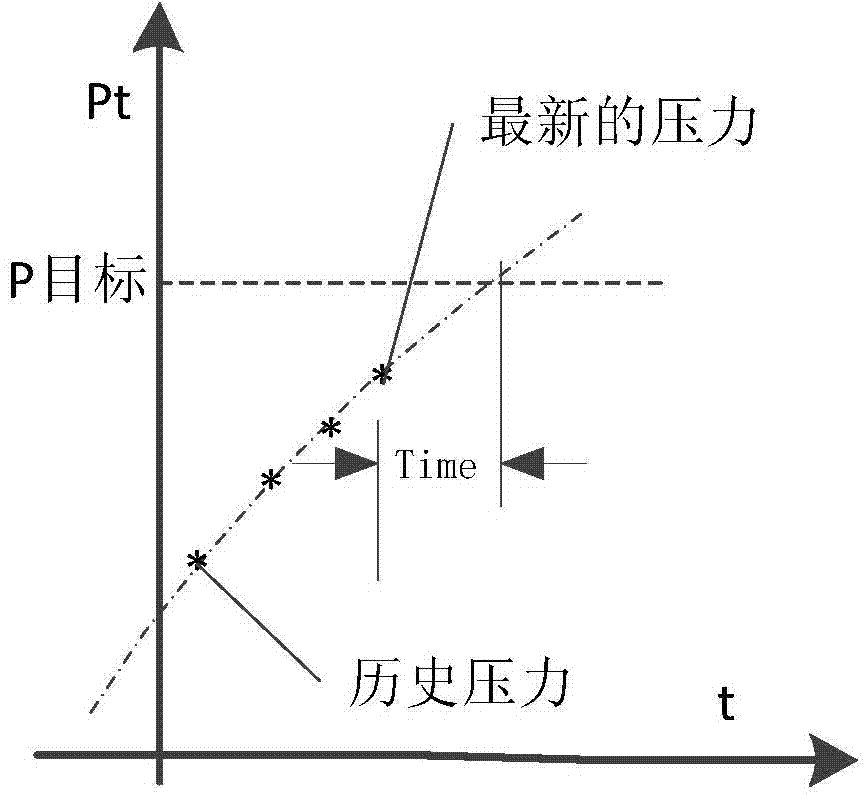

[0024] Step 1, the controller fits the pressure data and the time transformation curve.

[0025] S11. The controller controls the electromagnetic drive mechanism to open the electromagnetic valve, and the high-pressure air source inflates the pressure buffer tank.

[0026] S12. The controller collects the pressure data pt detected by the pressure gauge according to the preset frequency, records the collection time t, and sends the pressure data pt and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com