Transformer substation equipment video monitoring method based on RFID (Radio Frequency Identification) technique

A technology for video surveillance and substations, applied in the field of transformer equipment monitoring, can solve the problems of different functional locations, difficult to distinguish with human eyes, correlated real-time display, etc., to reduce misjudgment and misoperation, and improve the accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

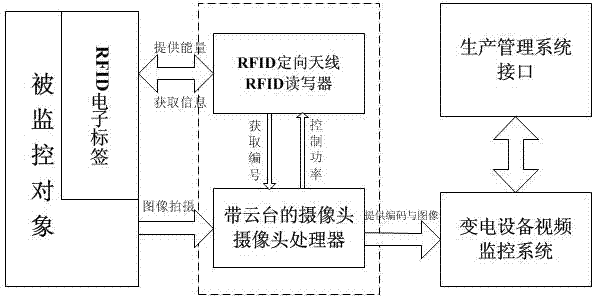

[0021] Refer to attached figure 1 : Taking the steps described in the summary of the invention as the main line, combined with the attached figure 1 The working principle and data flow process of the present invention in the specific implementation process are described.

[0022] Before the substation equipment is completed and put into production, the equipment's material classification, supplier, order number, equipment classification, equipment number, original manufacturer, and the equipment's unique functional position (ISPG) code in the entire system are written into the RFID through the handheld device In the user area of the electronic label. The functional location code of the equipment not only indicates the spatial location of the equipment, but also indicates the functional location of the equipment in the entire power grid, which indicates the role of the equipment in the power grid. Use this code to retrieve the health history information of materials, equipm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com