Sedum lineare brick and manufacturing method thereof

A production method, the technology of the Buddha grass brick, applied in the field of greening and vegetation, can solve the problems of no water retention function, grass seedlings are easily damaged, and need to be watered frequently, etc., to achieve long water retention time, solve virus and insect pests, and wind resistance performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

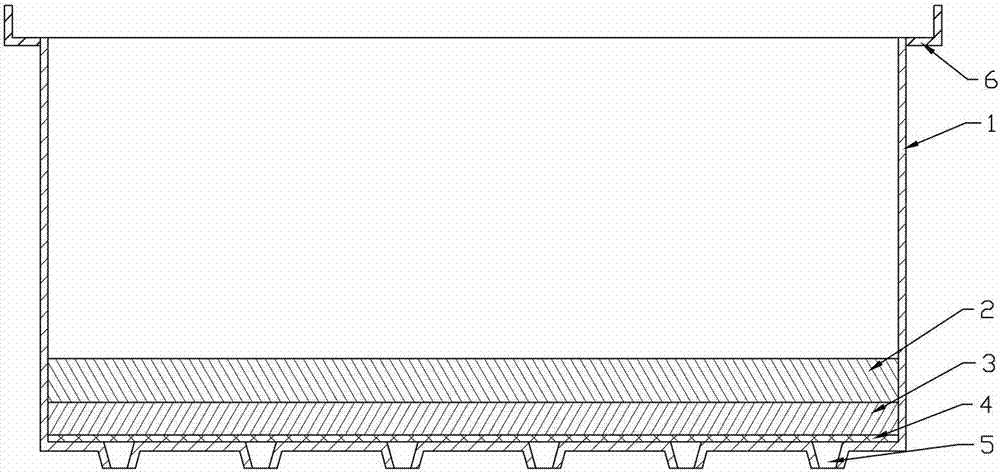

[0015] In embodiment 1, the present invention includes a plastic frame body 1, and the bottom of the plastic frame body 1 is provided with bumps protruding from the bottom surface. The feature is that the plastic frame body 1 is composed of a filter layer 4, a base material layer 3 and a Buddha from bottom to top. A grass layer 2, the top of the plastic frame 1 is provided with a reverse side 6, and a layer of sparse mesh nutrition layer is also provided on the base material layer 3, and the base material layer 3 is made of mushroom growth material, humus saw Humus, humus wheat husk, humus soil, or any combination thereof. The mushroom growth material accounts for 50%, the humus sawn material accounts for 20%, the humus wheat husk accounts for 10%, and the Ground soil accounts for 10%, ordinary soil accounts for 5%, poultry or animal manure accounts for 5%, mix the above ingredients evenly and carry out high-temperature fermentation for 15 days, and add 2% phosphate fertilizer t...

Embodiment 2

[0016] In Embodiment 2, the center of the bump of the present invention is provided with a water filter hole 5, which can reach the support and root separation, so that the root system of the grass is not easy to damage the roof, and excess water can be drained. See figure 1 , The rest is the same as in Example 1.

Embodiment 3

[0017] In Embodiment 3, the plastic frame body 1 of the present invention adopts a square or regular polygon or a special shape whose outer edges can be assembled with each other, and a suitable shape can be selected according to the specific conditions of the roof. See figure 1 , The rest is the same as the above embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com