Modularization combination high-efficient separation device

A separation equipment and modular technology, applied in the direction of liquid separation, separation methods, chemical instruments and methods, etc., can solve the problems of oil-water separation, inability to change the properties of raw materials, etc., and achieve high adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In a certain 3 million tons / year atmospheric and vacuum device in China, the modularized combined high-efficiency separation equipment with light-phase dispersed phase of the present invention is used to treat the electric desalination sewage therein.

[0029] Its specific operation process and effects are described as follows:

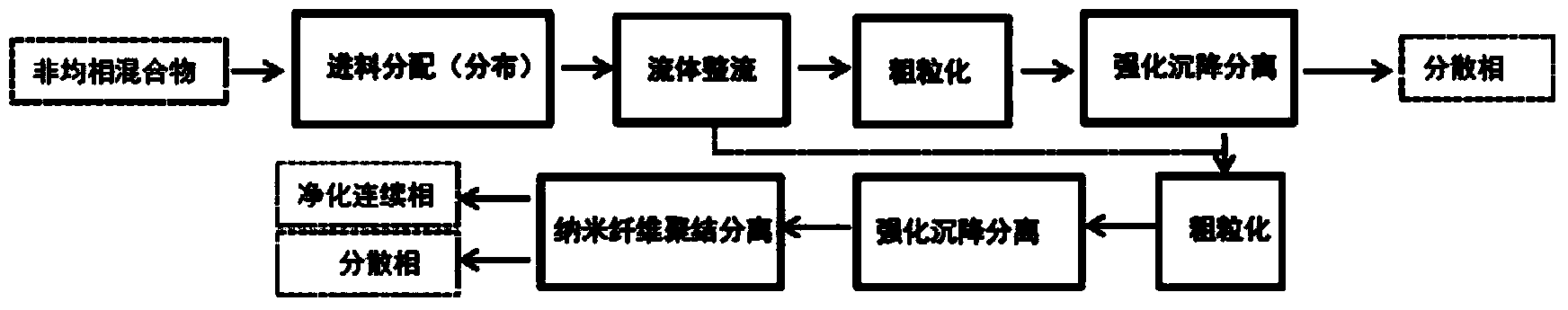

[0030] 1. Operating conditions of electric desalination wastewater

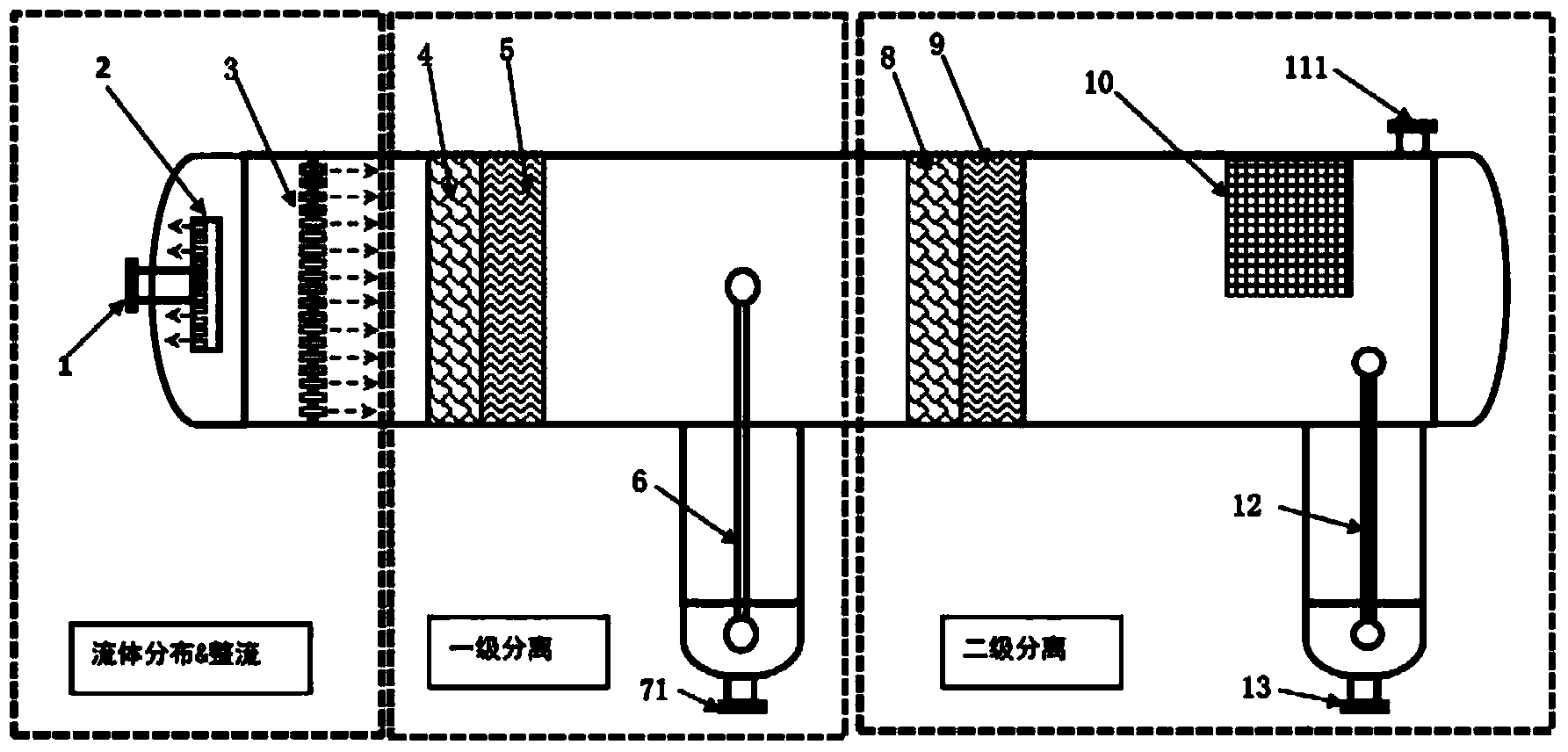

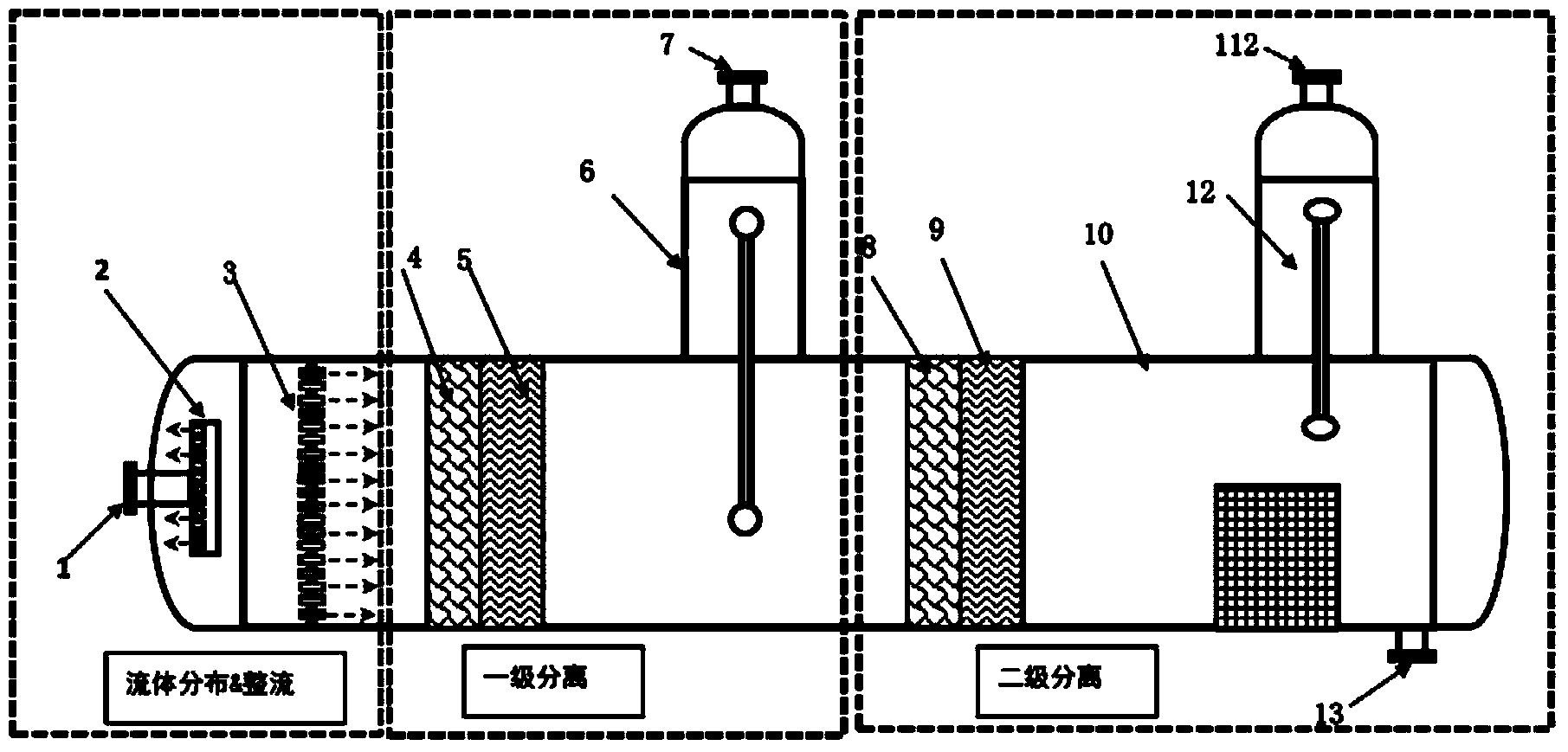

[0031] The main components are: under the volume flow rate, the oil content in water is 0.2-18%; the operating temperature is 40-65°C, and the operating pressure is 0.4MPa. like figure 1 As shown, since the oil is a dispersed phase and belongs to the process of deoiling in water, the oil bag is set on the top of the shell to recover the dirty oil, and because the content of the dirty oil in the water fluctuates widely, a two-stage combination is used for separation, that is, fluid distribution & Combination of rectification section, primary coarse granulation, primary enhanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com