High-frequency straight-seam welded pipe forming machine die quick changer

A technology of straight seam welded pipe and forming machine, applied in the field of machinery and equipment, can solve the problems of difficulty in ensuring the quality of mold installation, time-consuming, manpower, etc., and achieve the effects of shortening replacement time, reducing labor intensity, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

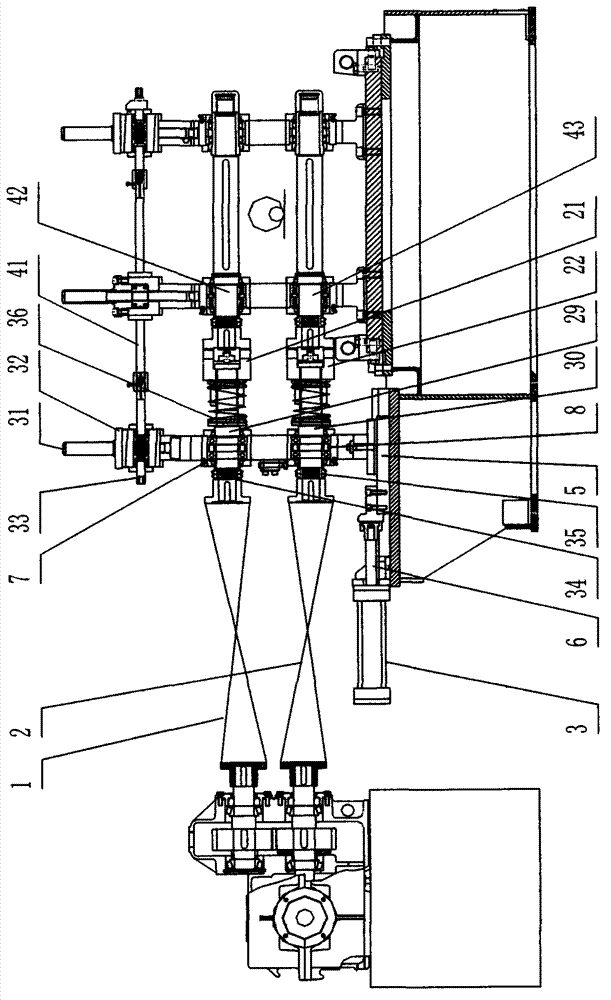

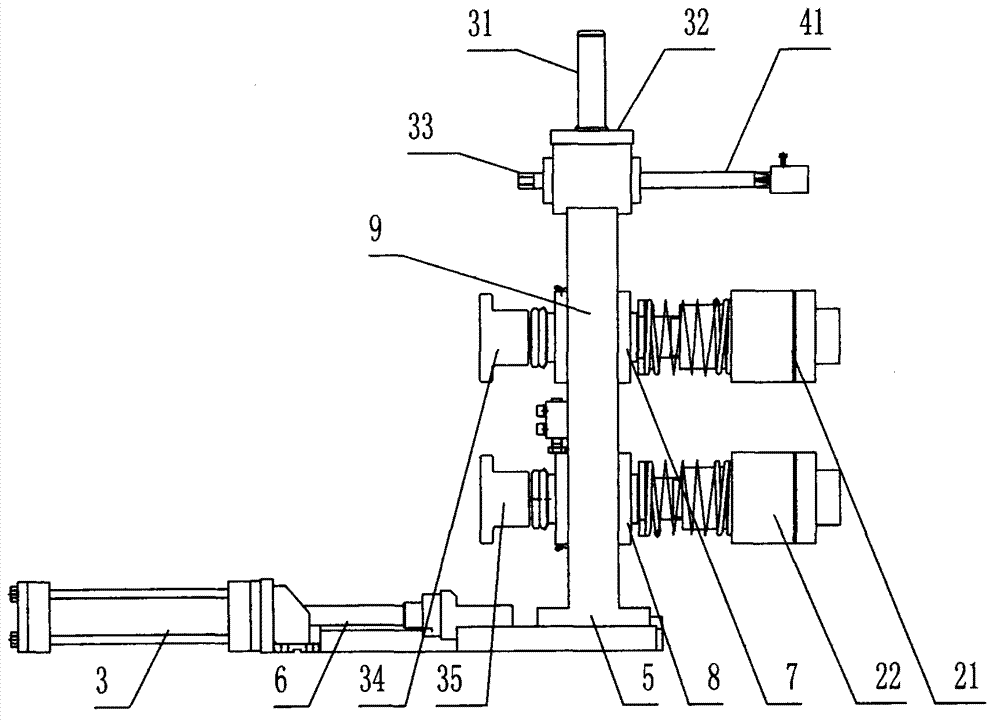

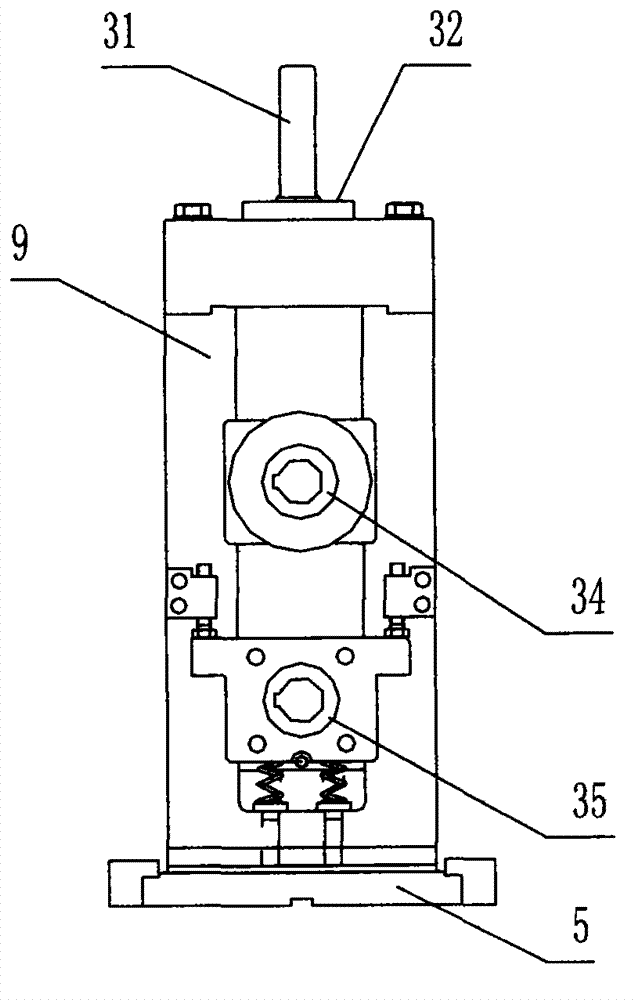

[0018] The present invention will be described below in conjunction with the accompanying drawings and examples: Embodiment: Referring to the attached drawings, the mold quick change device of the high-frequency straight seam welded pipe forming machine is characterized in that: a main connecting body is provided, and the main connecting body is provided with a base 5. The base is provided with a gantry support frame 9, and the lower bearing seat 8, the upper bearing seat 7, and the horizontal machine cap 32 are sequentially arranged in the middle of the support frame from bottom to top. The transmission shafts of the power, that is, the lower transmission shaft 30 and the upper transmission shaft 29, the front ends of the two transmission shafts are respectively connected to the rear ends of the two telescopic transmission shafts 2 and 1 of the high-frequency straight seam welded pipe forming machine through the connecting shaft pairs 35 and 34 connected, the rear ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com