Eucommia winged fruit shell gum grinding machine

A technology of eucommia samara and glue machine, which is applied in the field of eucommia samara shell processing equipment, can solve problems such as unsatisfactory results, troublesome operation, and environmental pollution, and achieve the effect of simple structure, applicable structure, and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

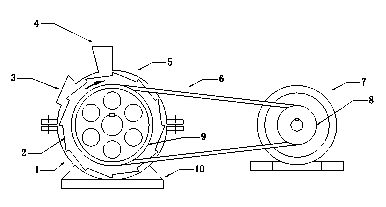

[0017] Now in conjunction with accompanying drawing, the present invention is described in further detail.

[0018] Such as figure 1 The Eucommia samara shell grinding machine shown includes a lower body 1, a rotor 2, a discharge port 3, a feed port 4, an upper body 5, a V-belt 6, a motor 7, a motor pulley 8, a rotor pulley 9 and a base 10 , The rubber mill is in the form of a rotor 2 with an upper and lower cover. The upper body 5 has a feed port 4 and a discharge port 3. The lower body 1 has an organic seat 10 and a bearing seat for the rotor 2.

[0019] The upper and lower bodies (5 and 1) are connected by bolts to form a cylindrical cavity.

[0020] The rotor 2 is placed in a cylindrical cavity and fixed on both sides of the lower body 1 by bearing seats.

[0021] The rotor 2 drives the rotor pulley 9 to rotate flexibly through the motor pulley 8 and the V-belt.

[0022] The rotor 2 has edges and corners, and the shortest distance from the cylindrical cavity is 5mm.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com