Structure principle applicable to ribbed steel bar taper thread roll forming equipment

A technology of rolling forming and structural principles, which is applied to threaded products, applications, household appliances, etc., can solve the problems of inconvenient construction of steel bar joints, waste of steel cost, and difficulty in determining quality control, so as to overcome insufficient connection strength and construction Convenience and the effect of saving joint materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

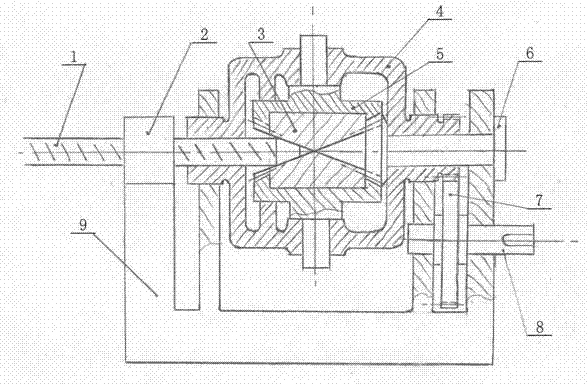

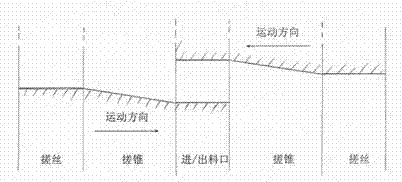

[0015] exist figure 1 Among them, a pair of rolling cone discs (5) and bevel gear shafts (6) equipped with conical surface molds (3) are installed in the rotary shell (4) to form a rotary rolling shell assembly. The two journals on the swivel casing are supported by the shaft holes on the frame (9), and the swivel casing assembly can be rotated on the frame through the drive gear (7); the flange end of the bevel gear shaft It is fixed by the frame and cannot be rotated. The hydraulic pliers (2) installed on the frame can clamp the steel bar (1) to be processed, so that the steel bar can make X, Y, Z, θ four-dimensional strong limit to the frame. The power of the equipment is input through the power input shaft (8), and intermittent transmission can be automatically realized, and the control is such that each rotation of the cone is a working cycle. The position of the inlet / outlet of the two cones is opposite and aligned with the inlet / outlet of the revolving shell, which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com