Method for producing edible vinegar by using byproducts from solid fermentation production of distillate spirit

A method of liquor and by-products, applied in the field of vinegar production, can solve the problems of waste of useful resources, increase the cost of sewage treatment and environmental pollution, etc., and achieve the effects of short production cycle, easy operation and lower production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

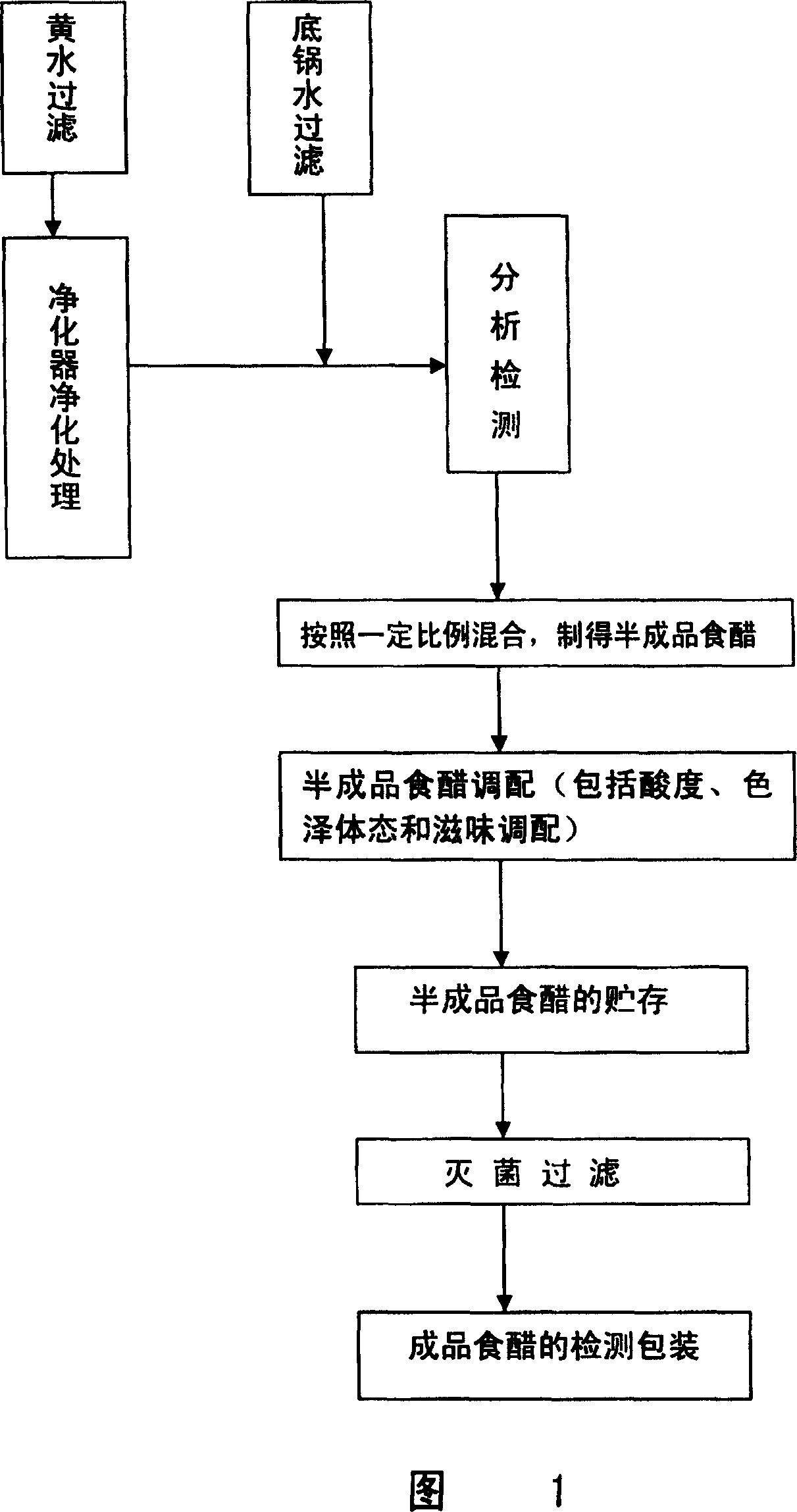

Method used

Image

Examples

Embodiment 1

[0043] Raw materials:

[0044] 1. Fresh yellow water

[0045] It comes from the by-products of Sichuan Tuopai Qujiu Co., Ltd. solid-state liquor brewing; fresh yellow water with normal color, aroma and taste.

[0046] 2. Bottom pot water

[0047]It comes from the by-products of Sichuan Tuopai Qujiu Co., Ltd. solid-state liquor brewing: the bottom pot water is mixed with fresh yellow water and wine tails at a ratio of 3:2, and then distilled to extract the wine. Bottom pot solution.

[0048] 3. The other auxiliary materials, glacial acetic acid, salt, and monosodium glutamate, are all commercially available products and have passed the test.

[0049] crafting process:

[0050] 1. Pretreatment of raw materials

[0051] Filter the yellow water and the bottom pot water respectively with filter cloth until clear and free of suspended matter, and purify the filtered yellow water with a purifier to remove peculiar smell, and obtain a purified solution for later use.

[0052] 2....

Embodiment 2

[0070] Raw materials:

[0071] 1. Fresh yellow water

[0072] From the by-products of Sichuan Tuopai Qujiu Co., Ltd. solid-state liquor brewing; fresh yellow water with normal color, aroma and taste.

[0073] 2. Bottom pot water

[0074] It comes from the by-products of Sichuan Tuopai Qujiu Co., Ltd. solid-state liquor brewing, using 100% fresh yellow water as distilled water, and distilling the solution in the bottom pot of the still left after the liquor is taken.

[0075] 3. The remaining auxiliary materials, glacial acetic acid, salt, and monosodium glutamate, are all commercially available products and have passed the test.

[0076] crafting process:

[0077] 1. Pretreatment of raw materials

[0078] Filter the yellow water and the bottom pot water with filter cloths until clear and free of suspended matter, and purify the filtered yellow water with a purifier to remove odors for later use.

[0079] 2. Analysis and detection of raw materials

[0080] The yellow wate...

Embodiment 3

[0097] Raw materials:

[0098] 1. Fresh yellow water

[0099] It comes from the by-products of Sichuan Tuopai Qujiu Co., Ltd. solid-state liquor brewing; fresh yellow water with normal color, aroma and taste.

[0100] 2. Bottom pot water

[0101] It comes from the by-products of Sichuan Tuopai Qujiu Co., Ltd. solid-state liquor brewing, using 100% fresh yellow water as distilled water, and distilling the bottom pot solution left after the liquor is taken.

[0102] 3. The remaining auxiliary materials, glacial acetic acid, salt, and monosodium glutamate, are all commercially available products and have passed the test.

[0103] crafting process:

[0104] 1. Pretreatment of raw materials

[0105] Filter the yellow water and the bottom pot water with filter cloths until clear and free of suspended matter, and purify the filtered yellow water with a purifier to remove odors for later use.

[0106] 2. Analysis and detection of raw materials

[0107] The yellow water and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com