Laminated glass on-line trimming device and method

A technology of laminated glass and trimming, applied in metal processing and other directions, can solve problems such as glass damage, and achieve the effects of avoiding scratches, improving work efficiency, and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

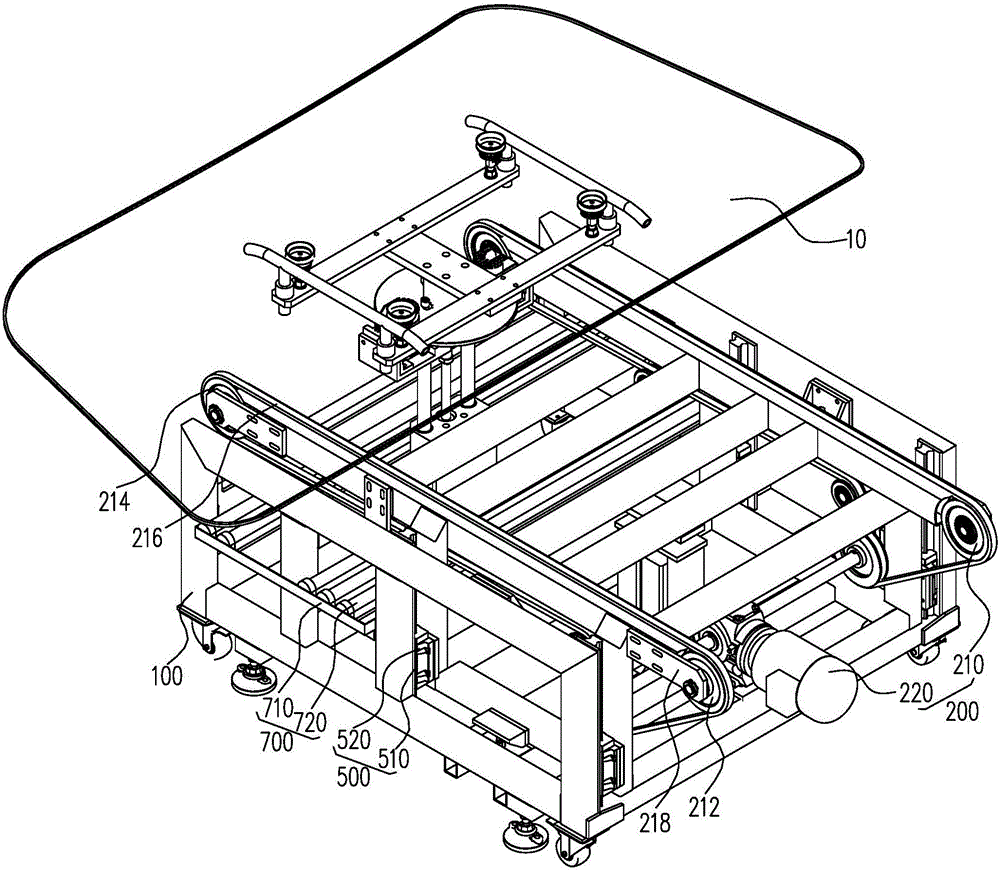

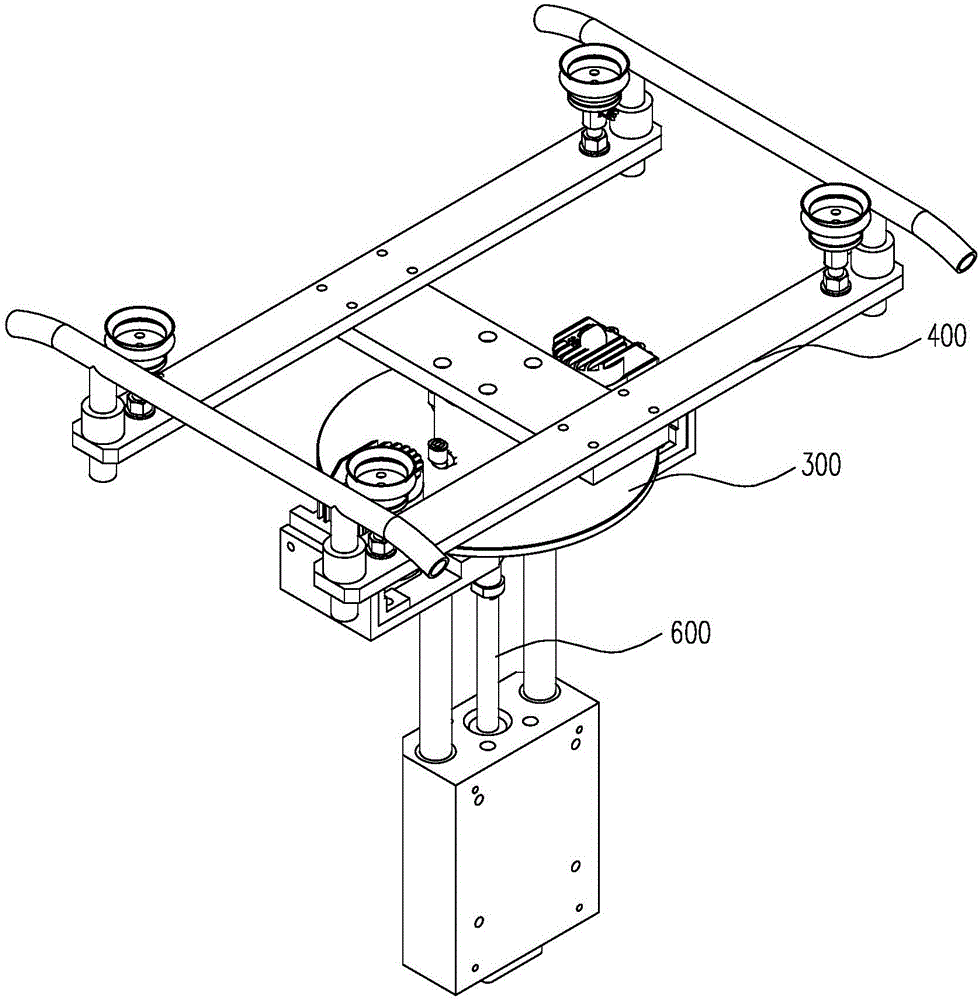

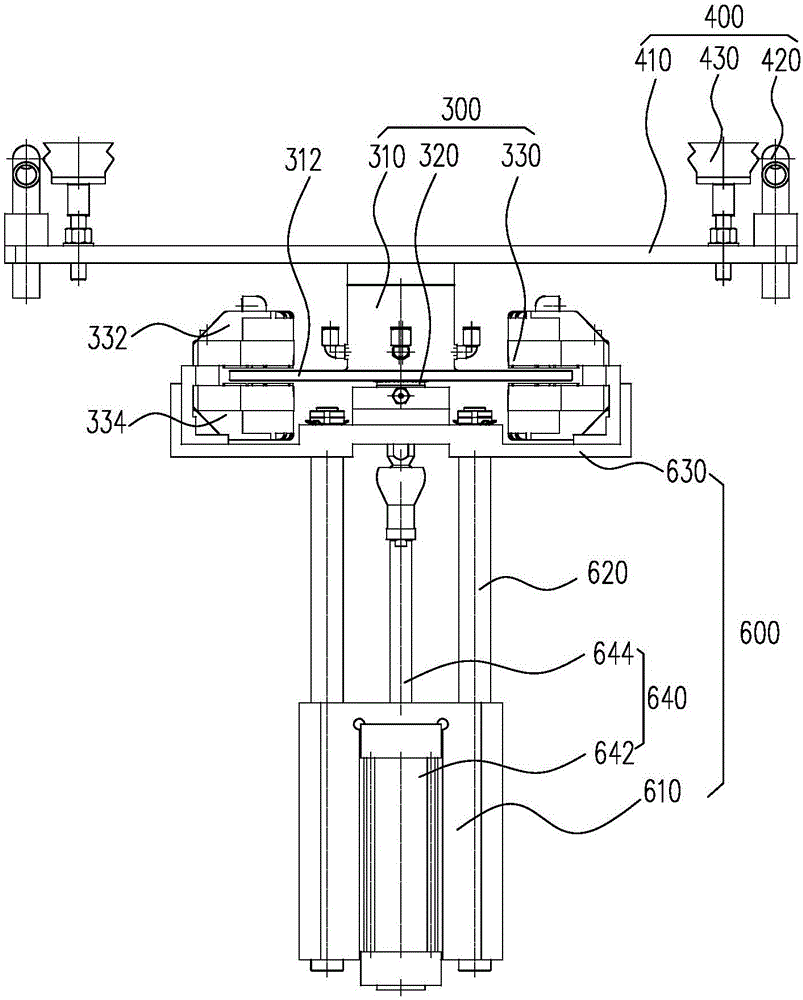

[0041] like figure 1 , figure 2As shown, an online trimming device for laminated glass includes a frame 100, a transmission mechanism 200, a rotation mechanism 300, a support mechanism 400, a first lifting mechanism 500, and a second lifting mechanism 600. The transmission mechanism 200 passes through the first lifting mechanism. The mechanism 500 is connected with the frame 100, the rotating mechanism 300 is arranged on the second elevating mechanism 600, the supporting mechanism 400 is arranged on the rotating mechanism 300, and the transmission mechanism 200 includes two oppositely arranged conveying lines 210 and driving The power mechanism 220 for the operation of the conveying line 210, the second lifting mechanism is arranged between the two conveying lines.

[0042] The on-line edge trimming device for laminated glass described in this embodiment directly installs the transmission mechanism 200 on the production line to carry the laminated glass 10 that needs to be t...

Embodiment 2

[0061] Such as Figure 5 As shown, an online trimming method for laminated glass adopts the online trimming device for laminated glass described in Embodiment 1, and the method includes the following steps:

[0062] S210: The second lifting mechanism lifts up the rotating mechanism and the supporting mechanism, and the supporting mechanism lifts the laminated glass from the transmission mechanism to rise to the first relief height, the first relief height is higher than the conveying line, and ensures that the interlayer Glass does not interfere with the conveyor line;

[0063] S220: The rotating mechanism rotates with the supporting mechanism and the laminated glass, and the operator trims the edge of the laminated glass with a trimming knife.

[0064] In the online trimming method of laminated glass described in this embodiment, the transmission mechanism maintains the initial height, and the second lifting mechanism lifts the rotating mechanism and the support mechanism, a...

Embodiment 3

[0066] Such as Image 6 As shown, an online trimming method for laminated glass adopts the online trimming device for laminated glass described in Embodiment 1, and the method includes the following steps:

[0067] S310: The first lifting mechanism lowers with the transmission mechanism, the support mechanism lifts up the laminated glass from the transmission mechanism, and the first lifting mechanism continues to descend to the second relief height, the second relief height is lower than the height of the conveying line, And ensure that the laminated glass does not interfere with the conveying line;

[0068] S320: The rotating mechanism rotates with the supporting mechanism and the laminated glass, and the operator trims the edge of the laminated glass with a trimming knife.

[0069] In the online edge trimming method for laminated glass described in this embodiment, the support mechanism maintains the initial height, and the first lifting mechanism lowers the transmission m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com