Novel steering-mode gear transmission of wheeled locomotive

A steering gear and gear transmission technology, applied to mechanical steering gears, steering controls mounted on vehicles, control devices, etc., can solve problems such as inability to turn or turn around, steering angle restrictions, etc., to achieve low cost, reduced steering time, The effect of reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

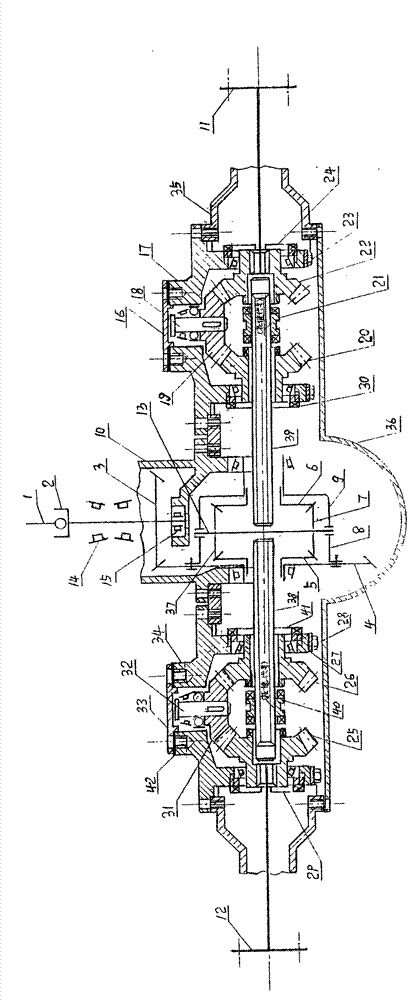

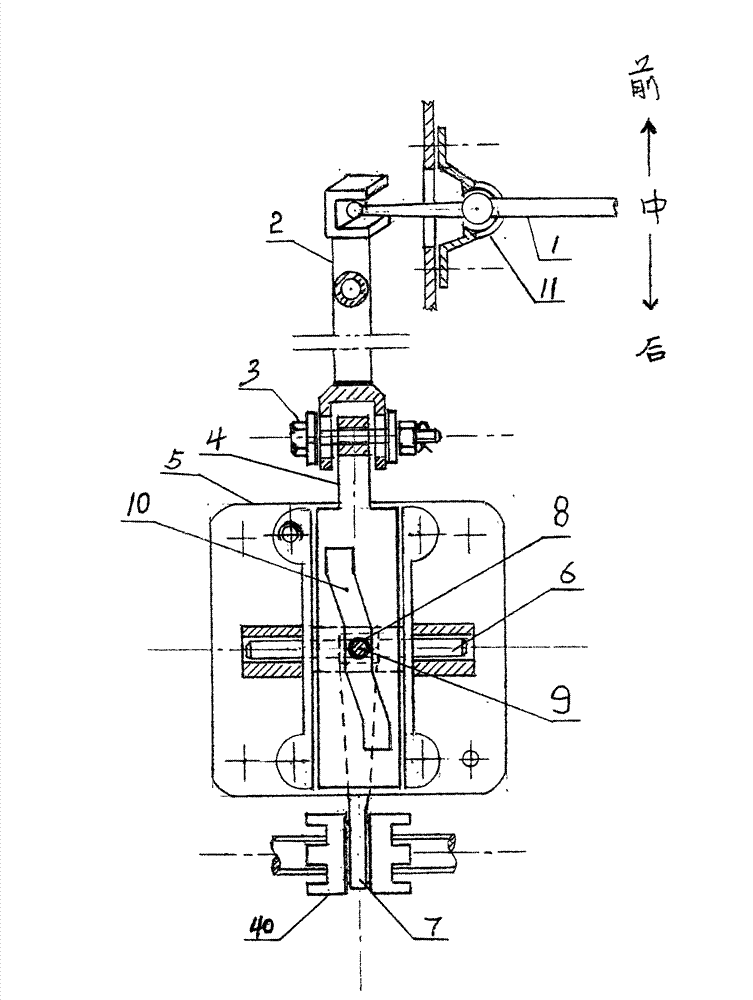

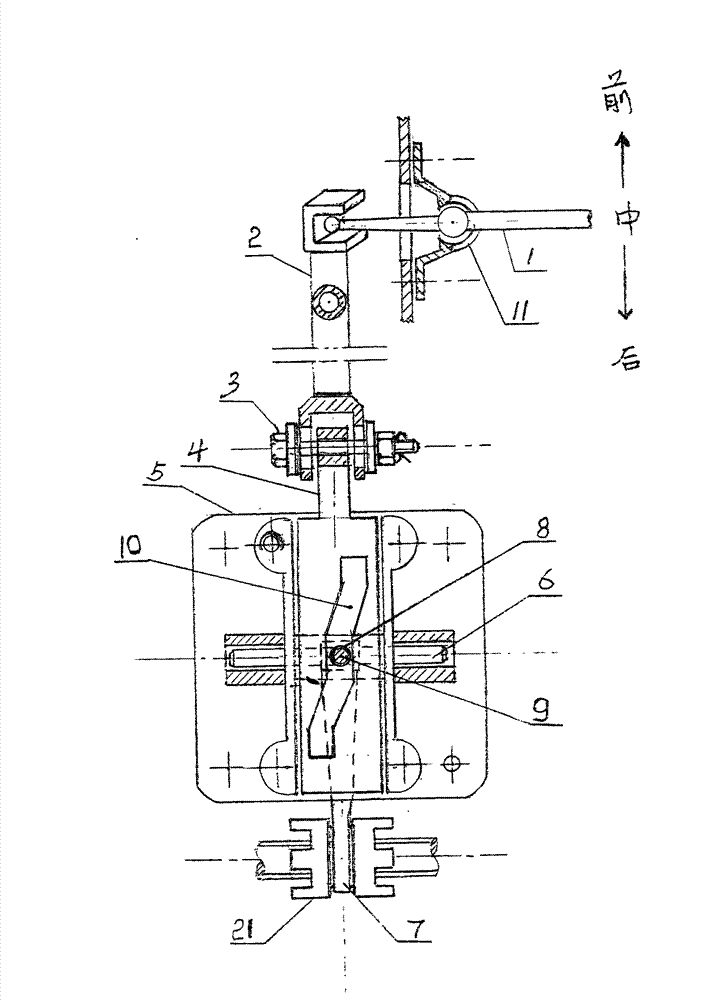

[0016] The existing final drive gears and planetary gears, left and right side bevel gears, and final drive shells remain unchanged. The right end of the spline shaft (38) of the device of the present invention is connected with the spline hole of the existing left side bevel gear (5), and rotates driven by the side gear to become the active spline of the left steering gear transmission of the device of the present invention axis. The left end of active spline shaft (38) is loaded onto the double-ended toothed wheel (40) that cooperates with spline and can slide left and right and rotates with axle, becomes active double-ended toothed wheel. On the left and right sides of the double-ended toothed wheel, coaxially load onto the toothed bevel gear (25) and (26) and can engage and separate with the double-ended toothed wheel, but be clearance fit with the axle. The tooth embedded bevel gear (25) is contained in the bearing seat on the left side of the gear housing (34), and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com