Granite simulation paint and preparation method thereof

A technology of rock flake paint and emulsion, applied in the direction of biocide-containing paint, antifouling/underwater paint, coating, etc. performance and weather resistance, simple construction, and the effect of reducing maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A rock flake paint, comprising component A and component B, wherein the composition of component A and the mass percentage of the total mass of the rock flake paint are:

[0043] Water-based acrylic emulsion: 15%

[0044] Coalescing aids: 1.5%

[0045] Defoamer: 0.25%

[0046] Antiseptic and antifungal agent: 0.8%

[0047] Hydroxyethylcellulose: 0.15%

[0048] water 10;

[0049] The composition of component B and the mass percentage of the total mass of rock flake paint are:

[0050] Aggregate: 64%

[0051] Composite slate 8.3%.

[0052] A method for preparing the above rock flake paint, comprising the following steps:

[0053] (1) Preparation of component A

[0054] (a) Put water into a clean paint vat, start the disperser and stir at 200RPM;

[0055] (b) Add film-forming aids and defoamers in sequence, and disperse for 3 minutes at 200 RPM;

[0056] (c) Add cellulose ether and disperse at 200RPM for 3 minutes;

Embodiment 2

[0062] A rock flake paint, comprising component A and component B, wherein the composition of component A and the mass percentage of the total mass of the rock flake paint are:

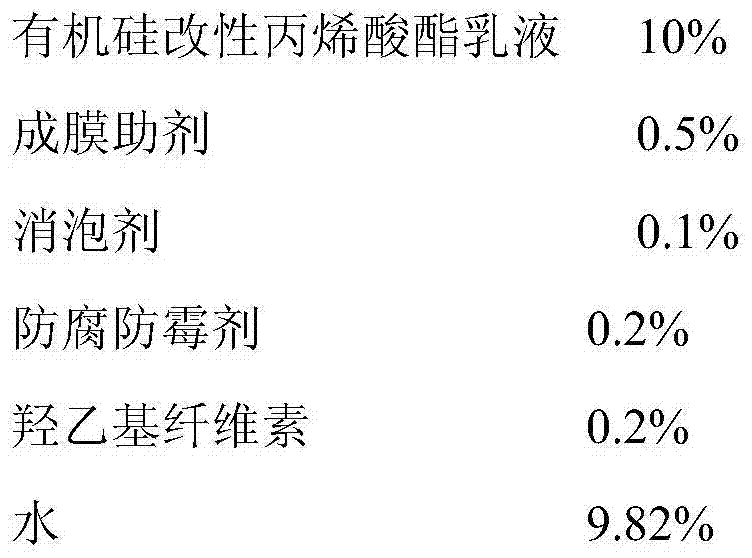

[0063]

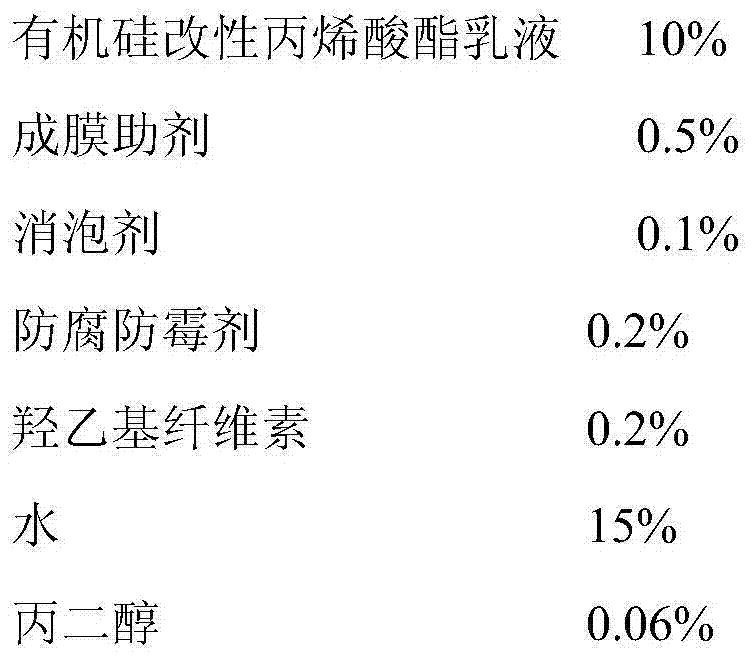

[0064]

[0065] The composition of component B and the mass percentage of the total mass of rock flake paint are:

[0066] Granite gravel: 70%

[0067] Composite rock slice 9%.

[0068] A method for preparing the above rock flake paint, comprising the following steps:

[0069] (1) Preparation of component A

[0070] (a) Put water into a clean paint vat, start the disperser and stir at 300RPM;

[0071] (b) Add film-forming aids and defoamers in turn, and disperse for 3 minutes at 300 RPM;

[0072] (c) Add cellulose ether and disperse at 300RPM for 3 minutes;

[0073] (d) When the cellulose ether is completely wetted and stirred evenly, adjust the pH to 8.0-9.0, and when the viscosity increases, increase the speed to 2000RPM to disperse for 3 minutes;

[0074] (e) Put in the emulsio...

Embodiment 3

[0078] A rock flake paint, comprising component A and component B, wherein the composition of component A and the mass percentage of the total mass of the rock flake paint are:

[0079] Water-based acrylic emulsion: 15%

[0080] Coalescing aids: 1.5%

[0081] Defoamer: 0.25%

[0082] Antiseptic and antifungal agent: 0.8%

[0083] Hydroxyethylcellulose: 0.15%

[0084] water 10;

[0085] The composition of component B and the mass percentage of the total mass of rock flake paint are:

[0086] Aggregate: 64%

[0087] Composite rock slice 8.3%.

[0088] A method for preparing the above rock flake paint, comprising the following steps:

[0089] (1) Preparation of component A

[0090] (a) Put water into a clean paint vat, start the disperser and stir at 200RPM;

[0091] (b) Add film-forming aids and defoamers in sequence, and disperse for 3 minutes at 200 RPM;

[0092] (c) Add cellulose ether and disperse at 200RPM for 3 minutes;

[0093] (d) When the cellulose ether is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com