A kind of growth method of single crystal diamond thin film

A single crystal diamond, growth method technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of limiting the application of single crystal diamond thin film and the deterioration of crystal quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

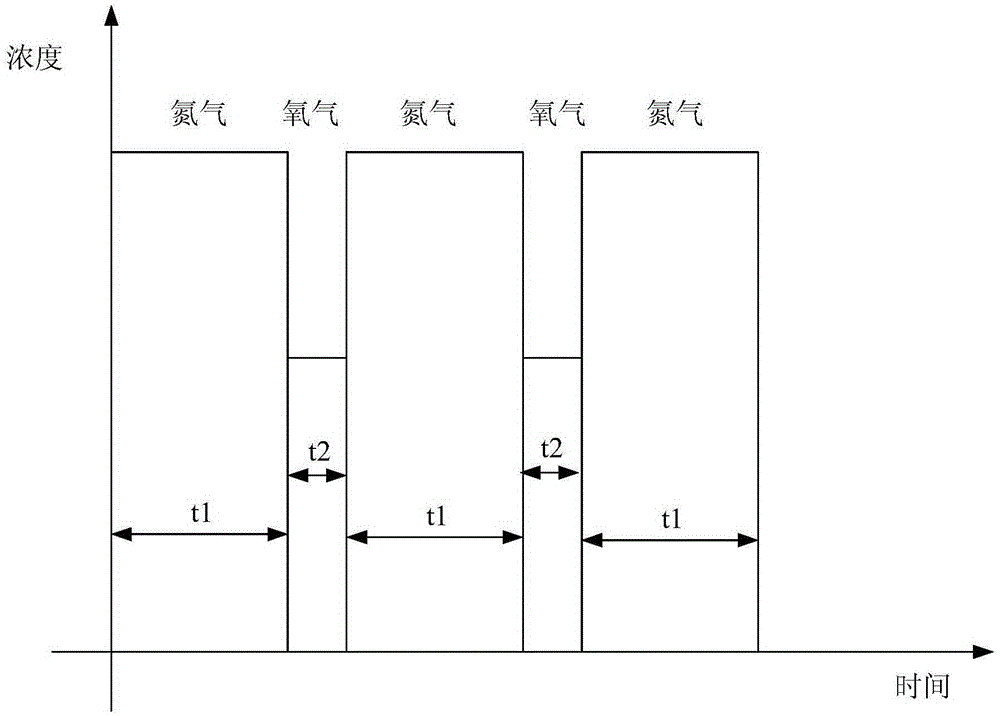

[0016] The invention introduces a small amount of oxygen when growing a single crystal diamond film, can remove nitrogen impurities, reduce carbon vacancies formed near each nitrogen atom due to nitrogen doping, and reduce silicon and hydrogen impurity levels. In a word, the present invention can eliminate defects such as impurities and vacancies in the single crystal diamond film while maintaining a certain growth rate, not only forming a transparent and colorless single crystal diamond film, but also improving the quality of the single crystal diamond film.

[0017] A method for growing a single crystal diamond thin film of the present invention, comprising: controlling the temperature of the diamond growth surface so that the temperature gradient of the diamond growth surface is less than 20°C; A single-crystal diamond film is grown by microwave plasma vapor deposition under a certain growth temperature, and reaction gases are introduced into the deposition chamber. The gase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com