Patents

Literature

30results about How to "Limit formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cr-free high-performance weatherable bridge steel and preparation method thereof

InactiveCN102534384AImprove welding performanceReduced carbide formationRoll mill control devicesMetal rolling arrangementsChemical IngredientsAlloy steel

The invention belongs to the manufacture field of low alloy steel, in particular to Cr-free high-performance weatherable bridge steel and a preparation method thereof. The Cr-free high-performance weatherable bridge steel provided by the invention contains the following chemical ingredients in percent by mass: 0.02-0.05% of C, 0.20-0.30% of Si, 0.6-1.00% of Mn, no more than 0.02% of P, no more than 0.010% of S, 0.20-0.40% of Cu, 0.30-0.80% of Ni, 0.04-0.07% of Nb, 0.005-0.015% of Ti, no more than 0.02% of Al and the balance of Fe and impurities. The Cr-free high-performance weatherable bridgesteel provided by the invention is formed by adopting two-stage rolling, wherein the rolling temperature of rough rolling in a first stage is 1,050-1,070 DEG C, the rolling temperature of fine rolling in a second stage is 900-950 DEG C, and the temperature for final rolling is 800-850 DEG C. The Cr-free high-performance weatherable bridge steel provided by the invention has excellent comprehensive mechanical properties and welding properties, does not contain the toxic element Cr, and meanwhile, has excellent resistance to atmospheric marine corrosion.

Owner:NORTHEASTERN UNIV +1

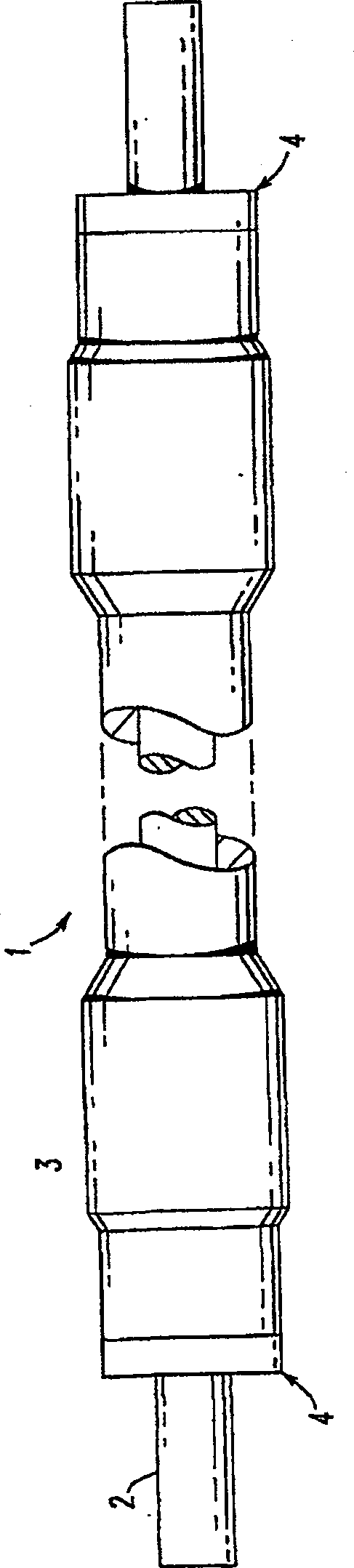

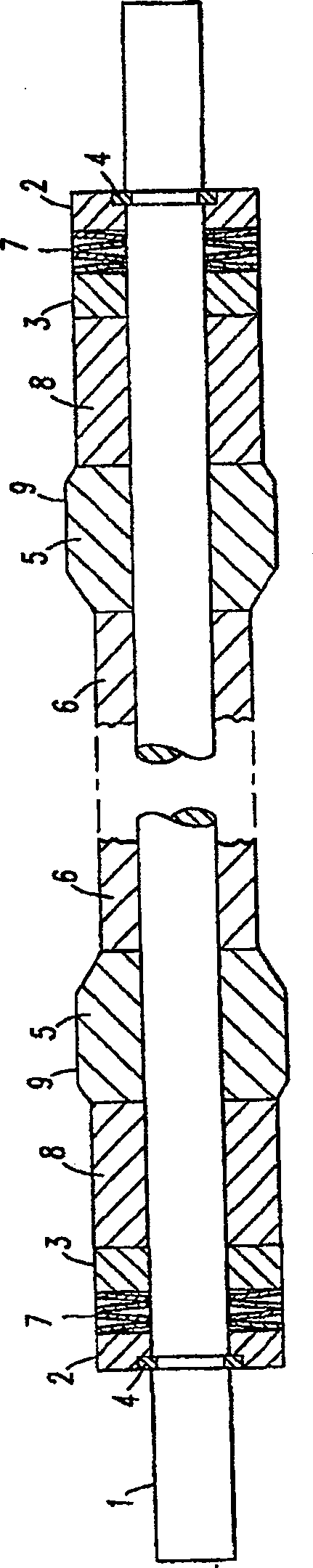

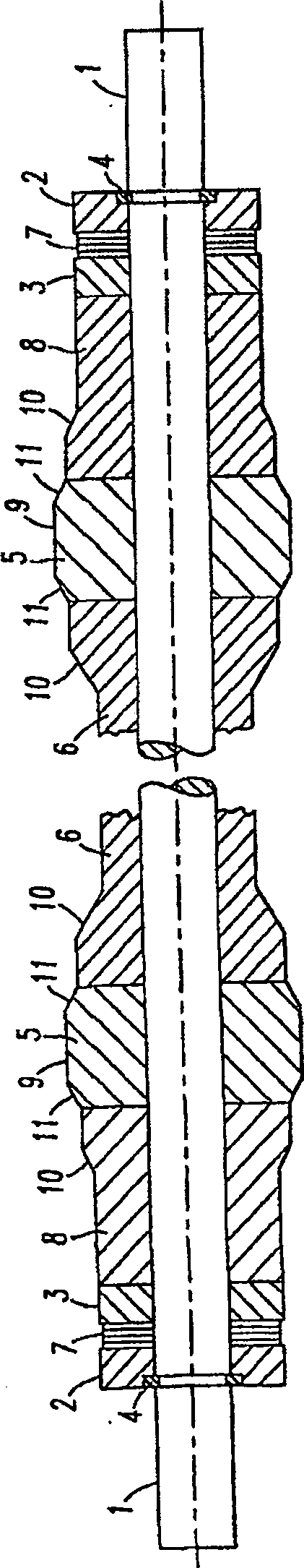

Non-dusting roll for tft glass

InactiveCN1871186AAvoid deformationOvercome limitationsGlass transportation apparatusRollersFiberMechanical property

A refractory roll cover is described that reduces the amount of noxious dust during the production of glass sheet. The roll cover comprises a plurality of segments, including low dusting millboard segments mechanically supported by highly rigidized compressed fiber segments. The millboard segments are adapted to contact the glass sheet. The millboard is chosen so that any dust produced has little affinity for the glass sheet or is not easily fluidized by convective currents. The highly rigidized compressed fiber has a fused surface that releases little dust. The resultant roll cover substantially eliminates dusting while providing a mechanically superior roll cover.

Owner:VESUVIUS CRUCIBLE CO

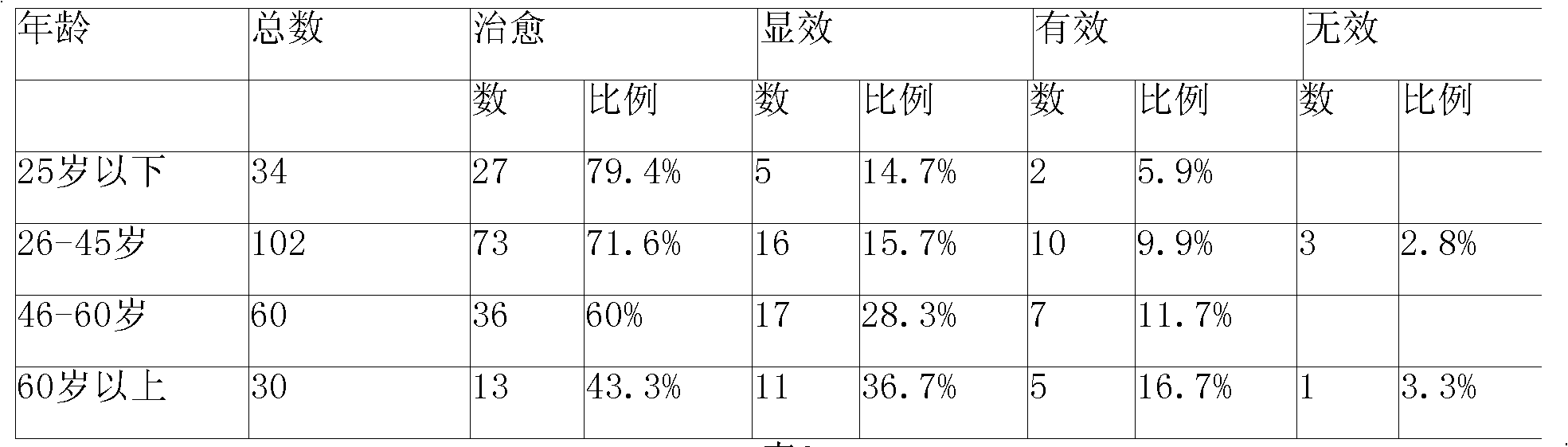

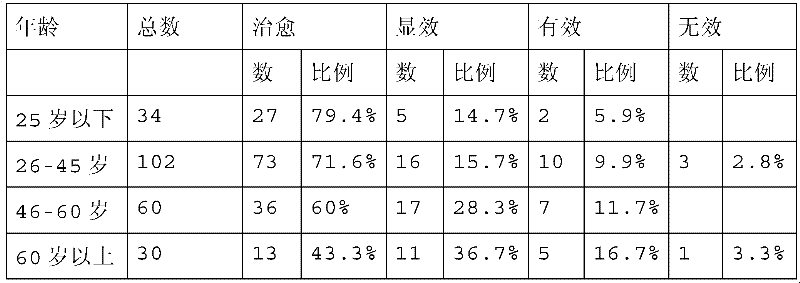

Chinese medicine for treating syringomyelia

InactiveCN1386531APromote absorptionLimit formationUnknown materialsDrug compositionsLycium barbarum fruitCurative effect

A Chinese medicine for treating syringomyelia, lateral sclerosis, chronic spondylitis, arachnoid adhesion, etc is prepared from 13 Chinese-medicinal materials including pilose antler, prepared rehmannia root, wolfberry fruit, ginseng, astragalus root, etc. Its advantages are high curative effect, no toxic by-effect and no recurrence.

Owner:阎洪臣

Polyamide reverse osmosis composite membrane and preparation method thereof

InactiveCN107617346AIncrease concentrationIncrease the degree of polymerizationGeneral water supply conservationWater/sewage treatment bu osmosis/dialysisPolyamideSide chain

The invention discloses a preparation method of a polyamide reverse osmosis composite membrane. The preparation method includes providing of polyamine water-phase solution and performing of interfacial polymerization reaction, wherein polyether modified polydimethylsiloxane in concentration of 0.01wt%-2wt% is dissolved in the polyamine water-phase solution. The invention further provides the polyamide reverse osmosis composite membrane prepared according to the preparation method. In the preparation method, polyether modified polydimethylsiloxane serving as a surfactant is applied to preparation of the reverse osmosis composite membrane, has unique advantages as the surfactant due to low surface tension and long flexible side chains and enables increasing of the salt removing rate of the polyamide reverse osmosis composite membrane with low water flux influences.

Owner:宁波日新恒力科技有限公司

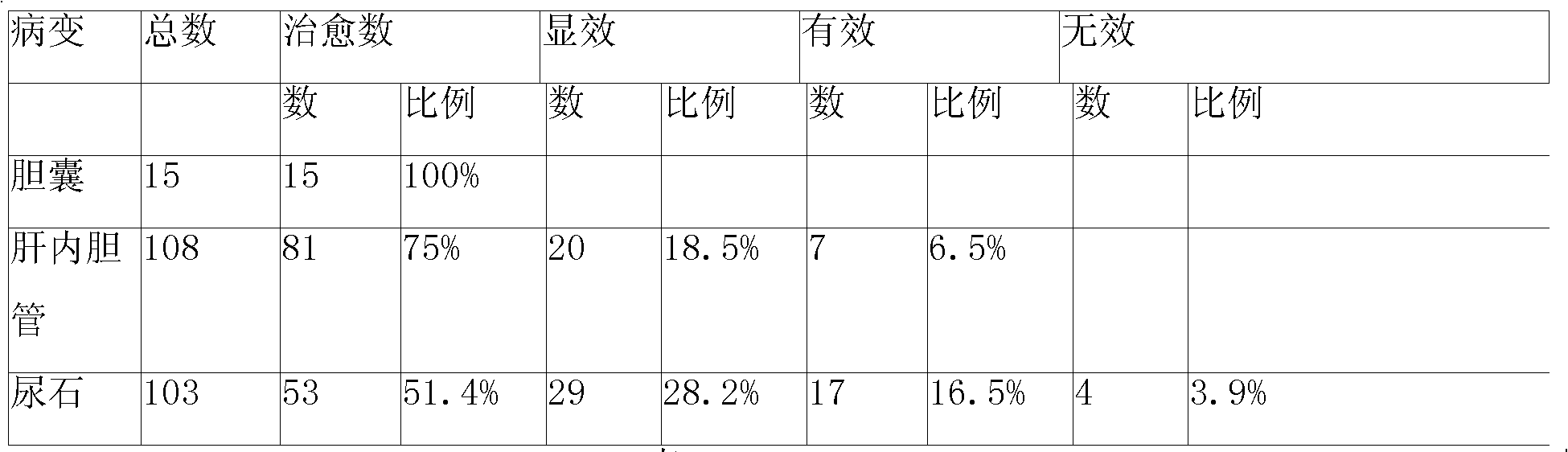

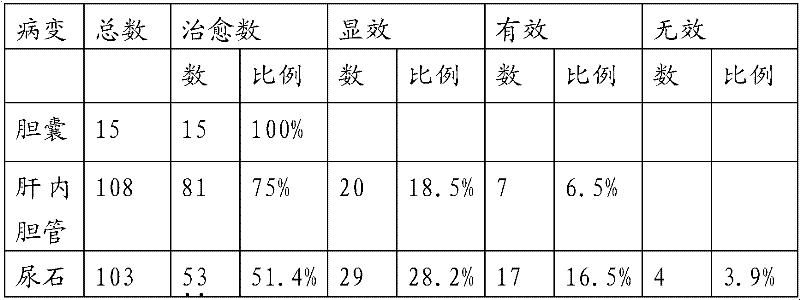

Chinese medicinal decoction for treating lithiasis and preparation method thereof

InactiveCN101590213AExcellent self-healing functionHas a diuretic effectDigestive systemPharmaceutical delivery mechanismBile JuiceBile secretion

The invention relates to Chinese medicinal decoction used for treating lithiasis and a preparation method thereof, and relates to Chinese medicinal decoction for treating biliary calculus and renal calculus diseases. Main components of the decoction comprise ophiorrhiza pumila, dandelion, rhizoma sparganii, zedoary, white paeony root, herba pyrrosiae, bupleurum, Szechuan lovage rhizome, peach kernel, radix curcumae, gizzard lining, curcuma, knotgrass, gardenia, dried old orange peel, immature tangerine peel, liquorice and the like. The Chinese medicinal decoction can effectively heal intrahepatic bile duct calculus after the gall bladder is extirpated and calcification and sand-like calculus in the kidney, and simultaneously can effectively promote choleresis, improve the self-healing function of the gall bladder, and recover the functions of the gall bladder and the kidney.

Owner:吕文华

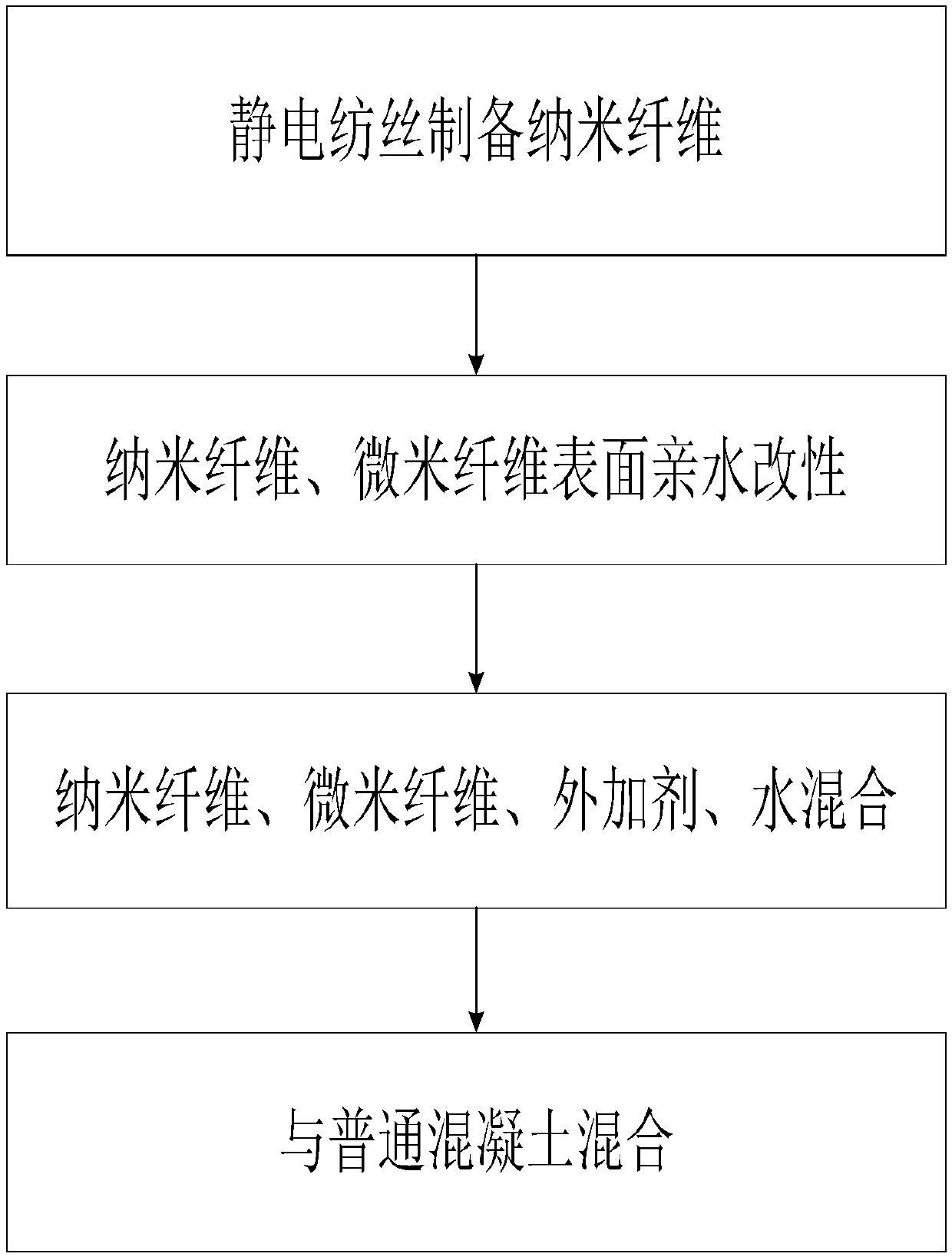

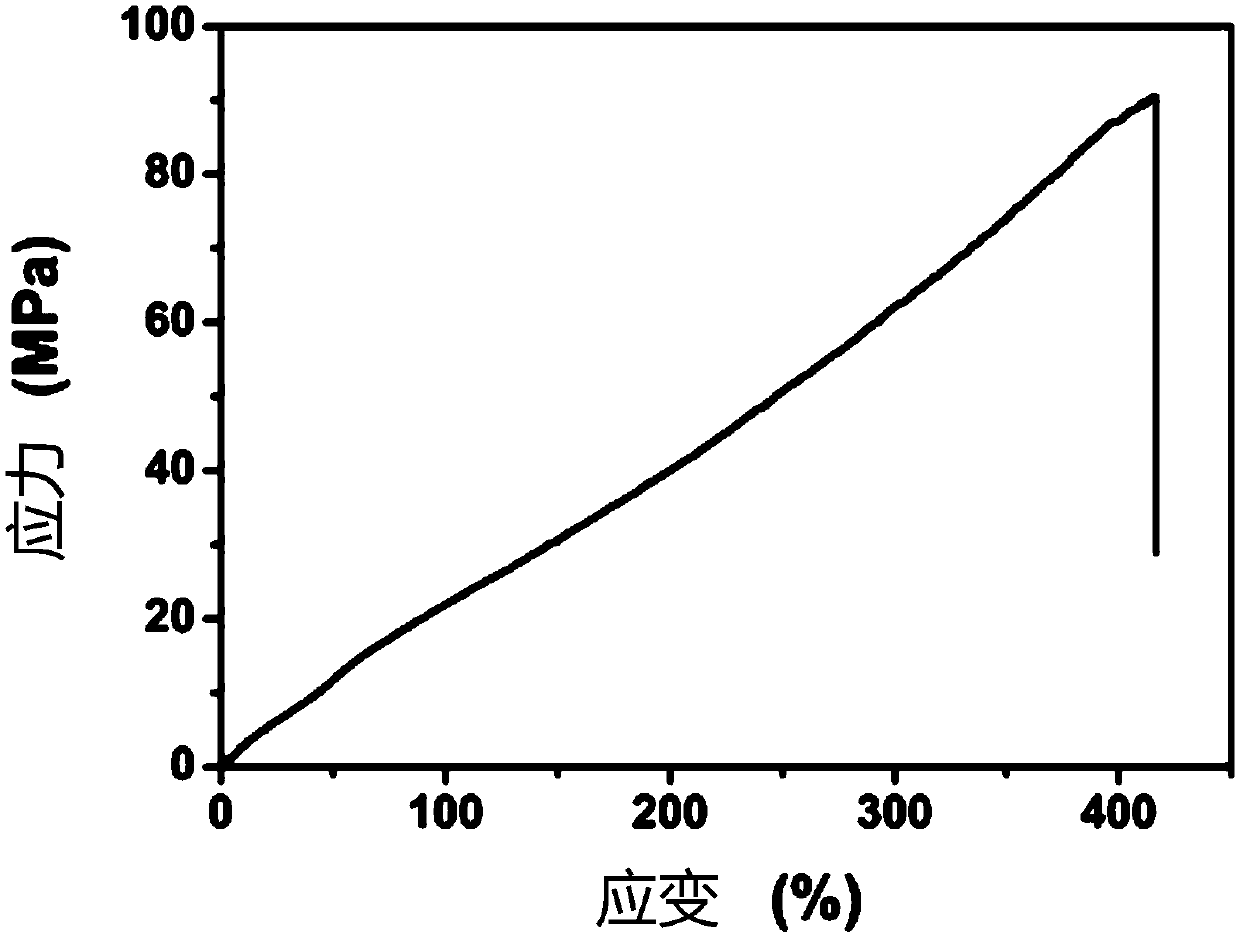

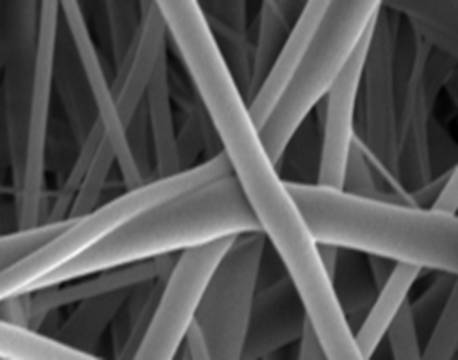

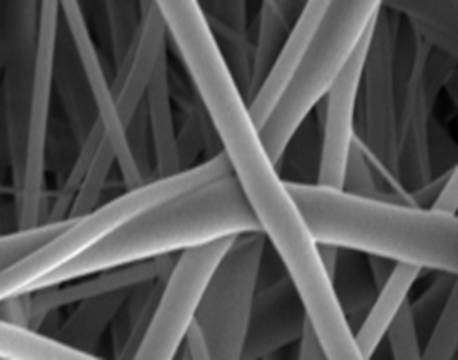

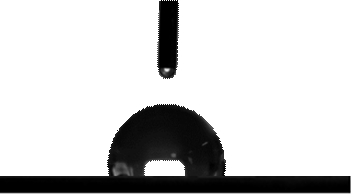

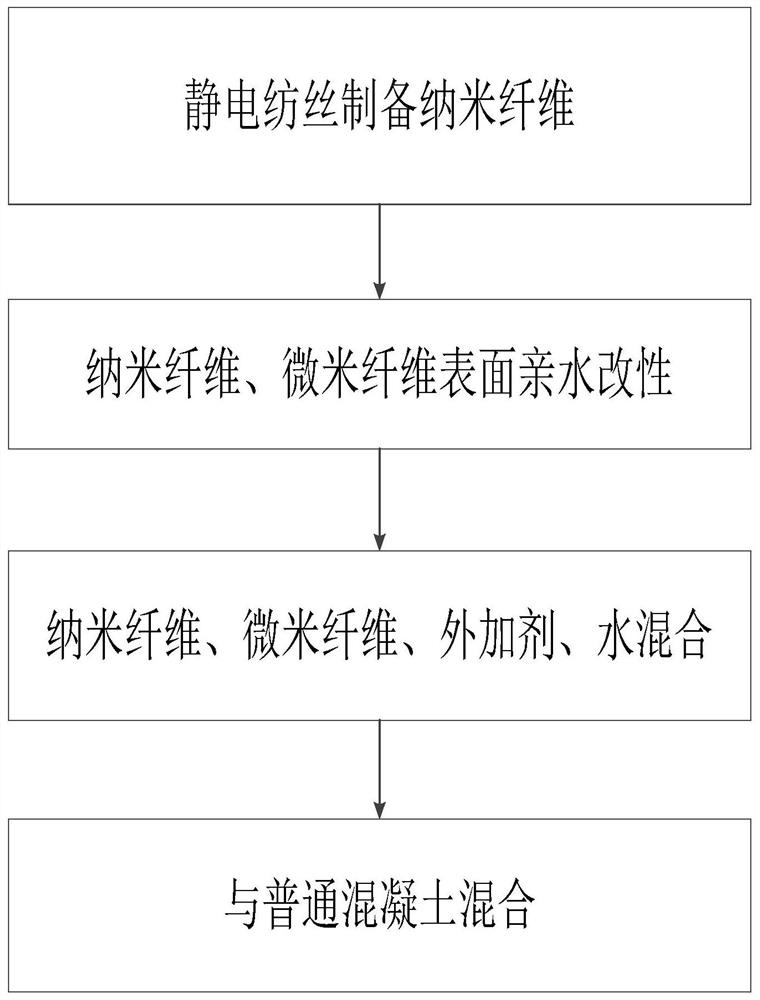

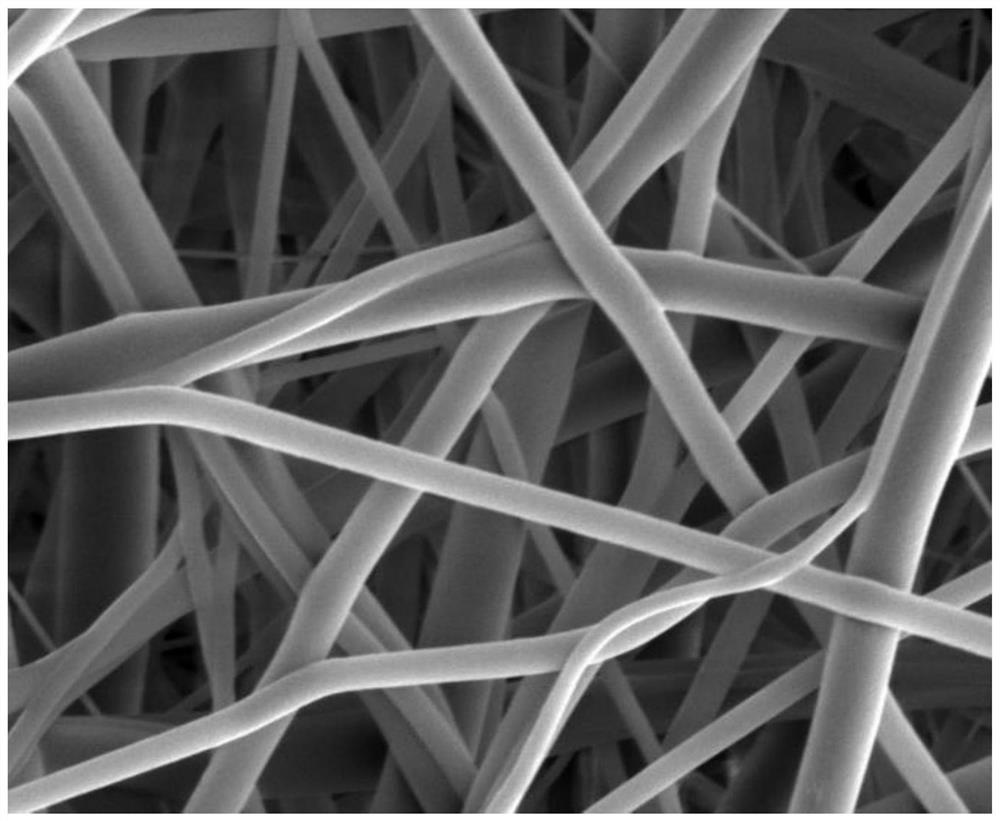

Micro-nano fiber reinforced concrete and preparation method thereof

The invention discloses micro-nano fiber reinforced concrete. The concrete comprises micro fiber with the surface provided with a first hydrophilic group and nano-fiber with the surface provided witha second hydrophilic group, wherein the content of the micro fiber in the concrete is set to be 2-5%, and the content of the nano-fiber in the concrete is set to be 5-10%. The nano fiber thins thick holes by filling hole structures between cement hydration products, the hole structure in the concrete is improved, the microstructure of the concrete is more compact, and harmful hole formation is effectively limited. The reinforced concrete obtained by blending the micro fiber, the nano-fiber and cement overcomes the characteristic of multiscale fracture, the nano-fiber and the micro fiber whichhave the surfaces provided with the hydrophilic groups and have the high elastic modulus greatly improve the mechanical property of the concrete, by adding additives, the mechanical property and the durability of the concrete are further enhanced, and the micro-nano fiber reinforced concrete with high bending resistance, high strength and high toughness is obtained.

Owner:UNIV OF SCI & TECH BEIJING

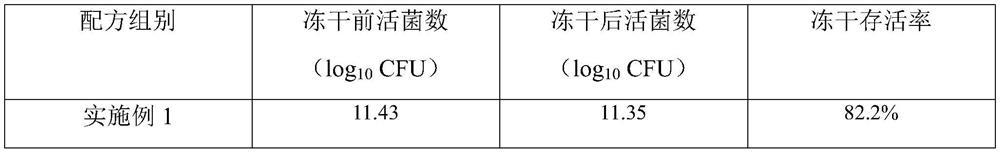

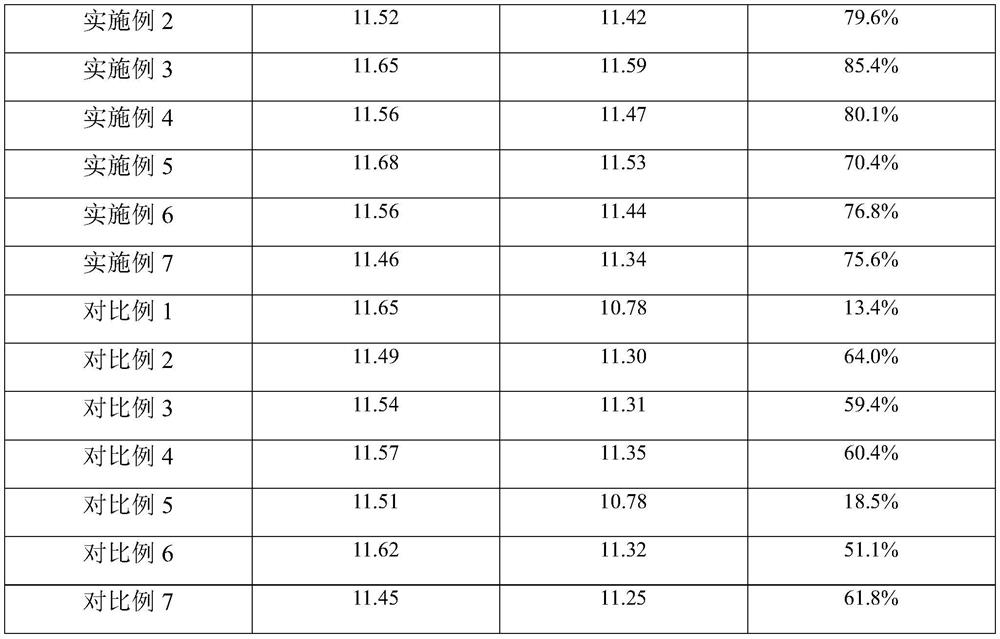

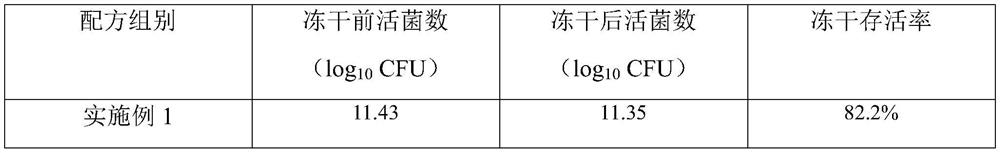

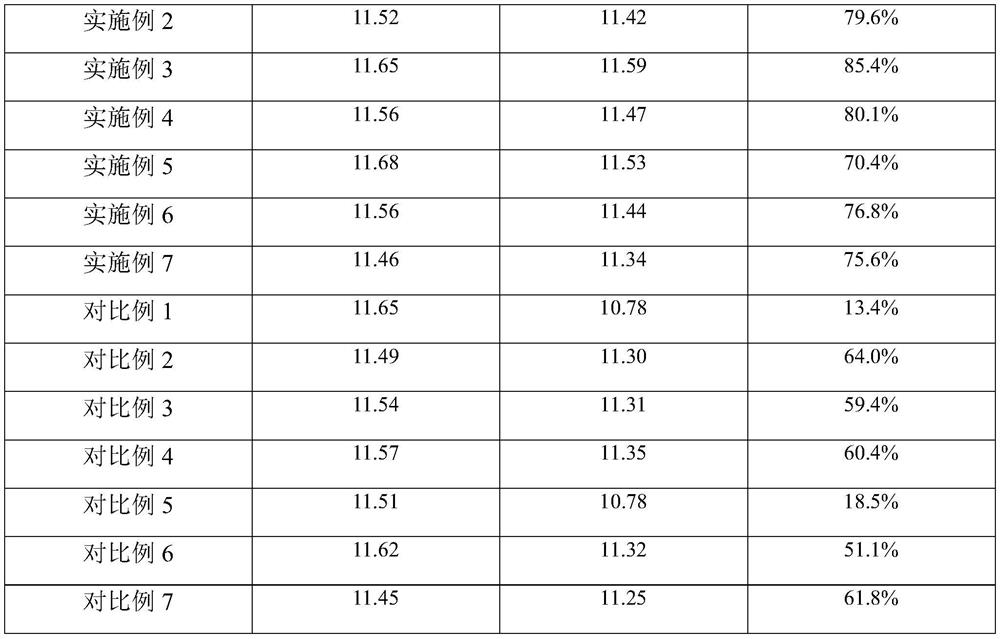

Freeze-drying protective agent, fecal microbiota freeze-dried product and preparation method of freeze-drying protective agent

ActiveCN112195103AProtected SurvivalSpeed up the outflowMicroorganism preservationVitamin CFreeze-drying

The invention belongs to the field of microorganisms, and particularly relates to a freeze-drying protective agent, a fecal microbiota freeze-dried product and a preparation method of the freeze-drying protective agent. The freeze-drying protective agent comprises polydextrose, mannitol, glycine, vitamin C and Tween 80; the freeze-drying fecal microbiota product prepared from the freeze-drying protective agent is high in fecal microbiota total fungus survival rate and superior to trehalose in effect; and the potential risk caused by trehalose, maltodextrin and the like can be reduced, and thefinal curative effect of the fecal microbiota transplanting product can be potentially improved.

Owner:SHENZHEN XBIOME BIOTECH CO LTD

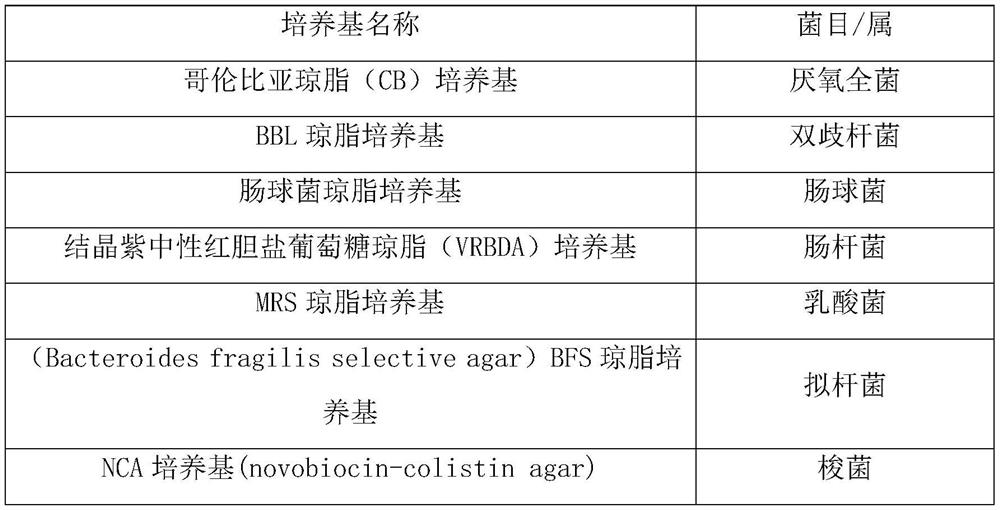

Adsorbent based on a zeolite and a silica-rich clay, and process for purifying hydrocarbon feeds

InactiveCN104226242AReduced responseForm a limitGas treatmentOther chemical processesSorbentHeteroatom

The present invention concerns an adsorbent comprising at least one zeolite selected from a zeolite of the 12 MR, 10 MR and 8 MR type and at least one binder comprising a clay with a Si / Al weight ratio of more than 2. It also concerns its preparation process and its use in a process for purifying a hydrocarbon feed comprising unsaturated molecules and at least one impurity comprising at least one heteroatom of the O, S or N type.

Owner:INST FR DU PETROLE

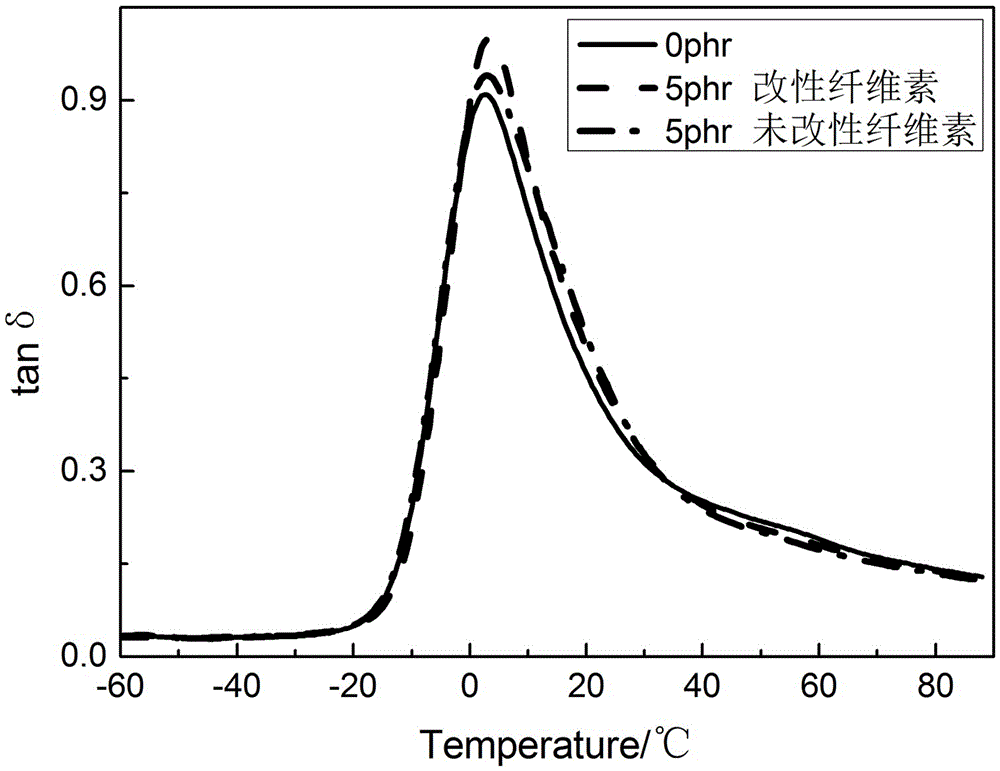

Method for preparing tire tread rubber by using modified microcrystalline cellulose

InactiveCN103627055BGood dispersionEnhanced interactionSpecial tyresRolling resistance optimizationRolling resistancePolymer science

The invention discloses a method for preparing tire tread rubber by use of modified microcrystalline cellulose, which comprises the steps of (I) modifying microcrystalline cellulose by use of functional ionic liquid; (II) applying the modified microcrystalline cellulose to a tread rubber reinforcing process, and partially replacing white carbon black with the modified microcrystalline cellulose by a conventional mixing process to obtain a rubber compound; performing vulcanization setting on the rubber compound at 130-180 DEG C according to the optimum vulcanizing time of the process to obtain vulcanized rubber. In the method disclosed by the invention, since the microcrystalline cellulose is modified by use of functional ionic liquid (containing double bonds, rubber accelerator or vulcanized group and the like), the dispersion of the microcrystalline cellulose in a rubber matrix is effectively improved, the interaction of the microcrystalline cellulose with the rubber matrix and the white carbon black is enhanced, and the formation of a white carbon black network structure is limited; by applying the microcrystalline cellulose to the tire tread rubber, the strength of the tread rubber can be improved, the wet slip resistance of the tread rubber is remarkably improved, and the rolling resistance against a tire is reduced; the preparation process is simple, and environmental pollution is avoided.

Owner:QINGDAO UNIV OF SCI & TECH

Cr-free high-performance weatherable bridge steel and preparation method thereof

InactiveCN102534384BGood effectHigh strengthRoll mill control devicesMetal rolling arrangementsMechanical propertyImpurity

The invention belongs to the manufacture field of low alloy steel, in particular to Cr-free high-performance weatherable bridge steel and a preparation method thereof. The Cr-free high-performance weatherable bridge steel provided by the invention contains the following chemical ingredients in percent by mass: 0.02-0.05% of C, 0.20-0.30% of Si, 0.6-1.00% of Mn, no more than 0.02% of P, no more than 0.010% of S, 0.20-0.40% of Cu, 0.30-0.80% of Ni, 0.04-0.07% of Nb, 0.005-0.015% of Ti, no more than 0.02% of Al and the balance of Fe and impurities. The Cr-free high-performance weatherable bridgesteel provided by the invention is formed by adopting two-stage rolling, wherein the rolling temperature of rough rolling in a first stage is 1,050-1,070 DEG C, the rolling temperature of fine rolling in a second stage is 900-950 DEG C, and the temperature for final rolling is 800-850 DEG C. The Cr-free high-performance weatherable bridge steel provided by the invention has excellent comprehensive mechanical properties and welding properties, does not contain the toxic element Cr, and meanwhile, has excellent resistance to atmospheric marine corrosion.

Owner:NORTHEASTERN UNIV LIAONING +1

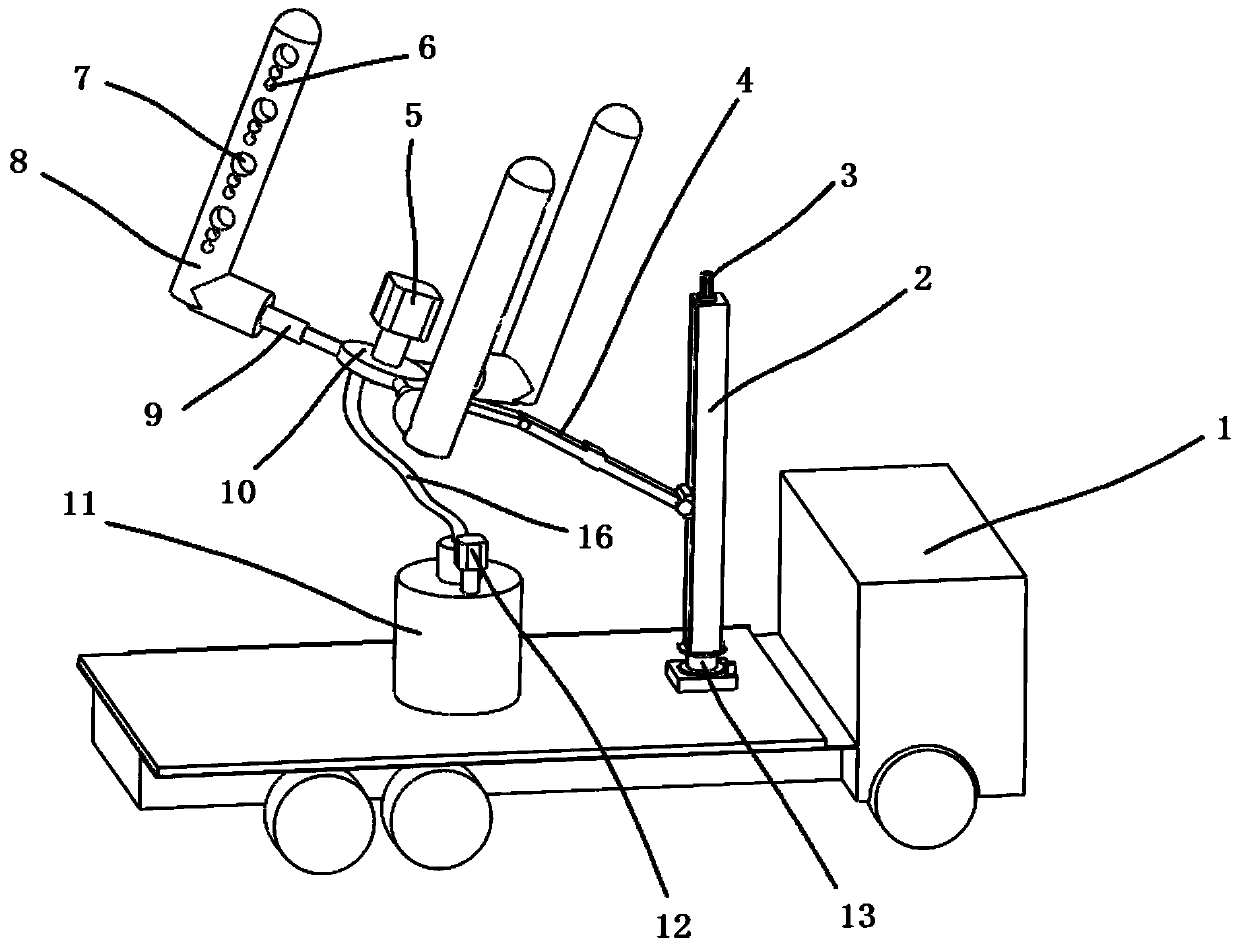

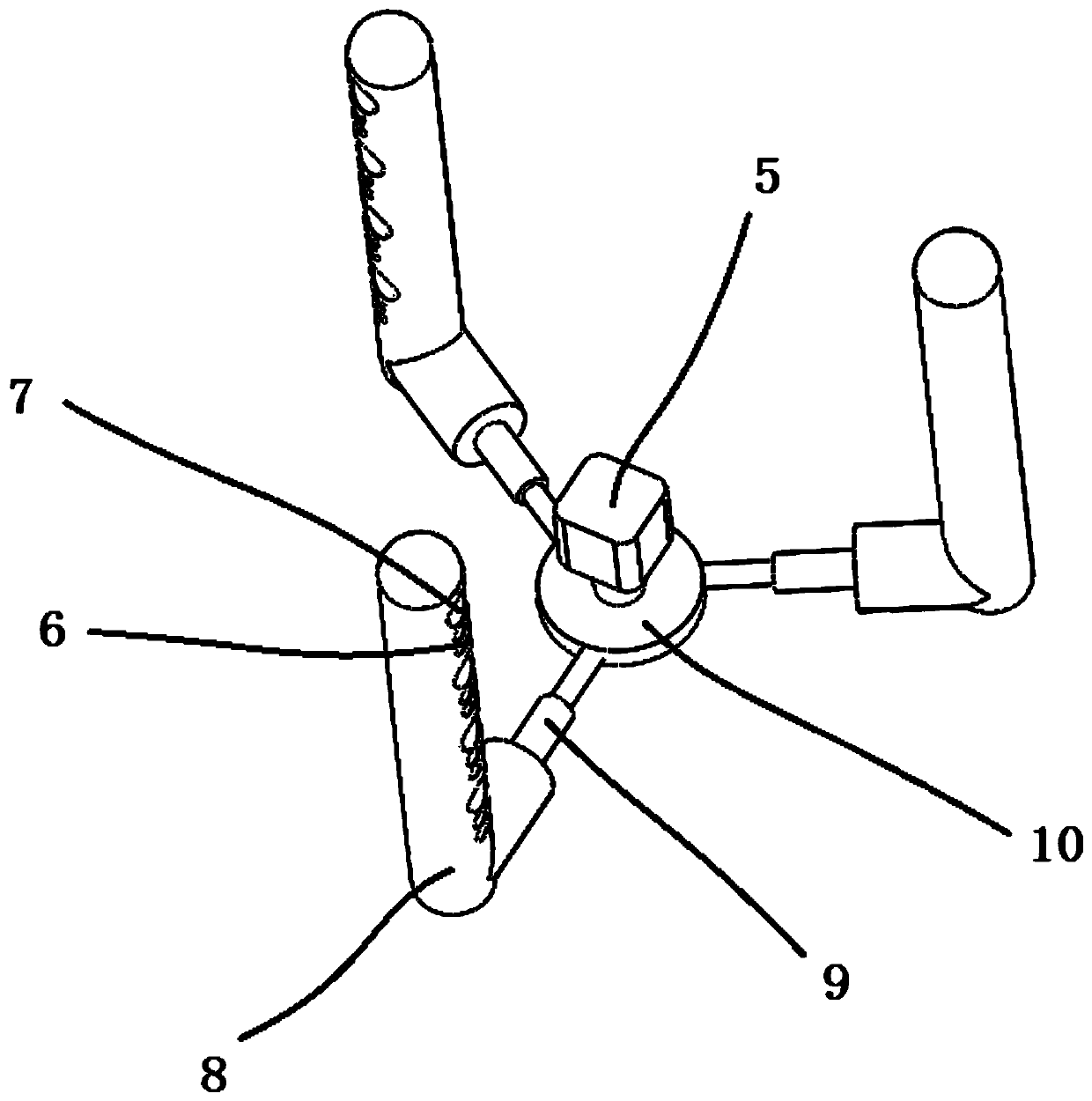

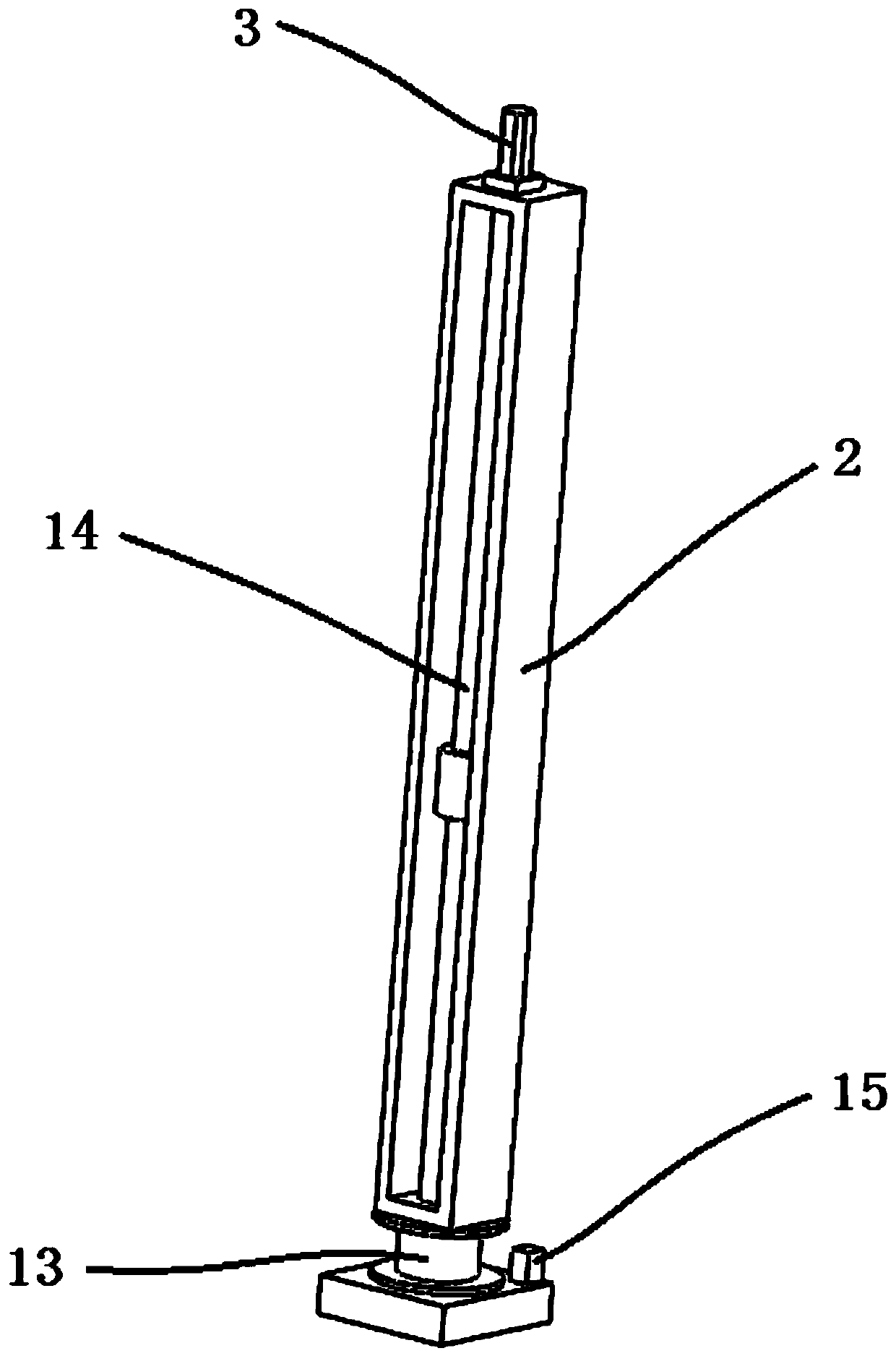

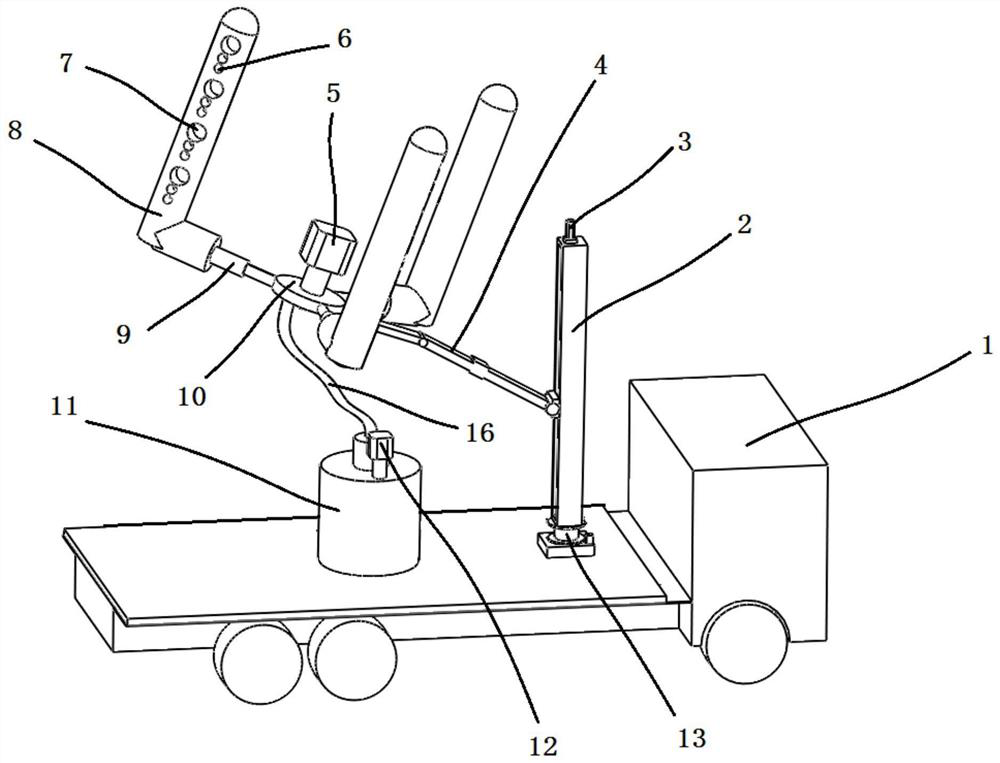

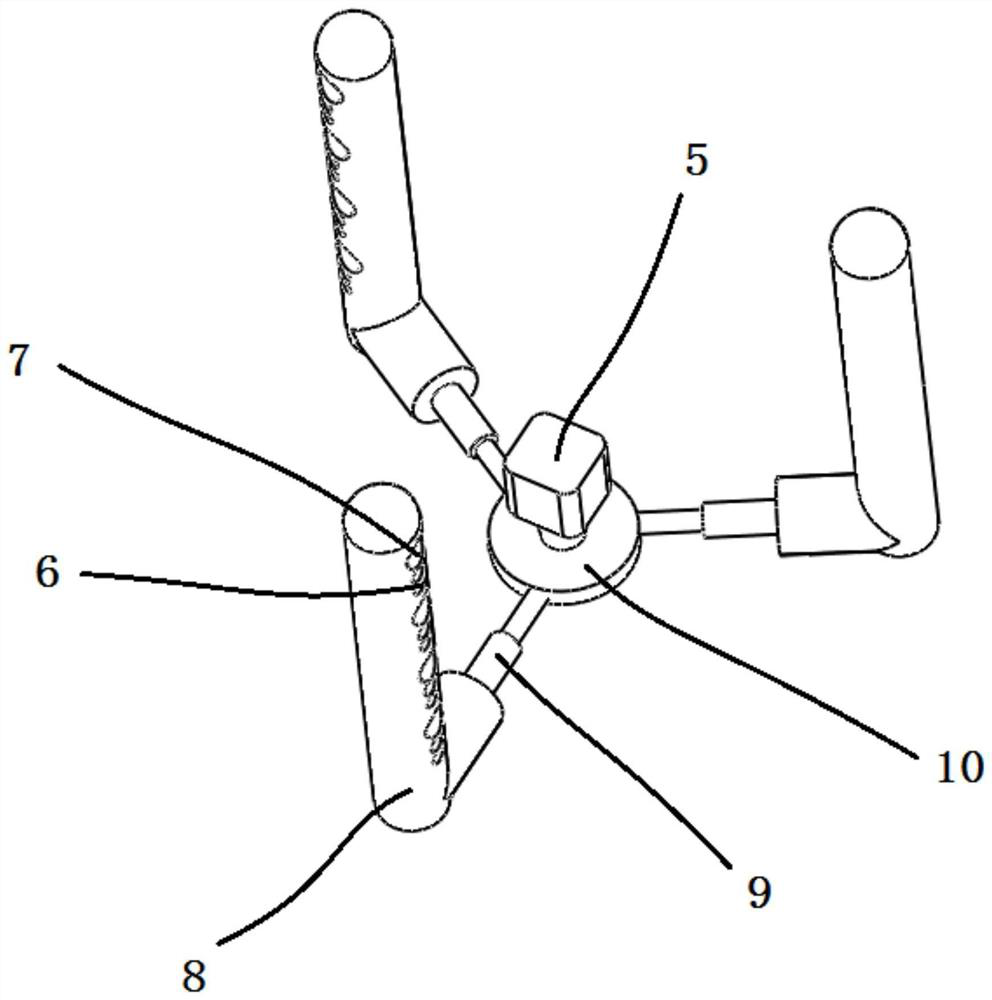

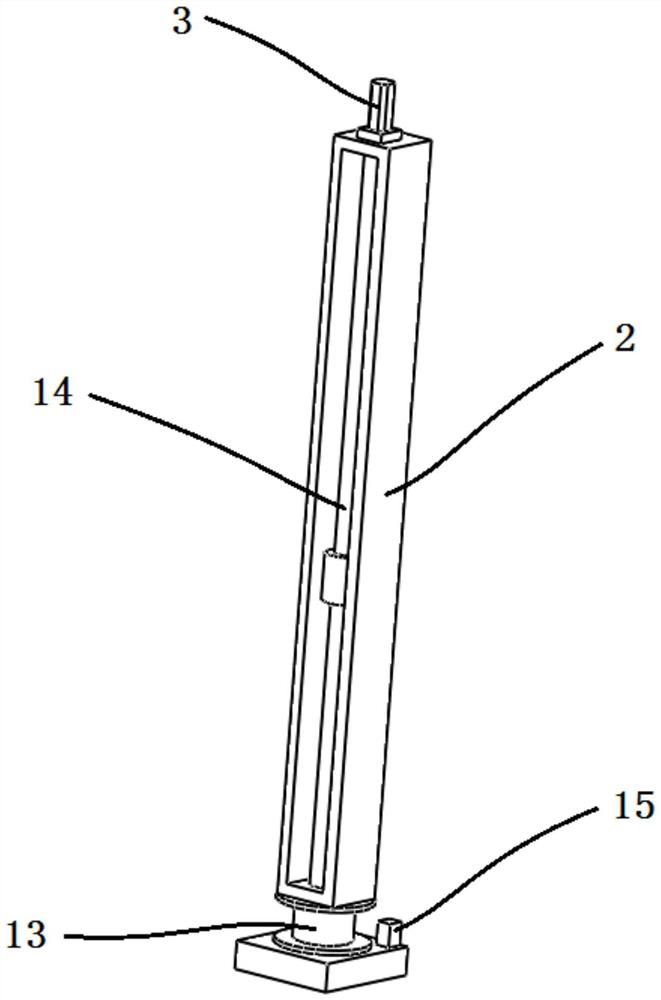

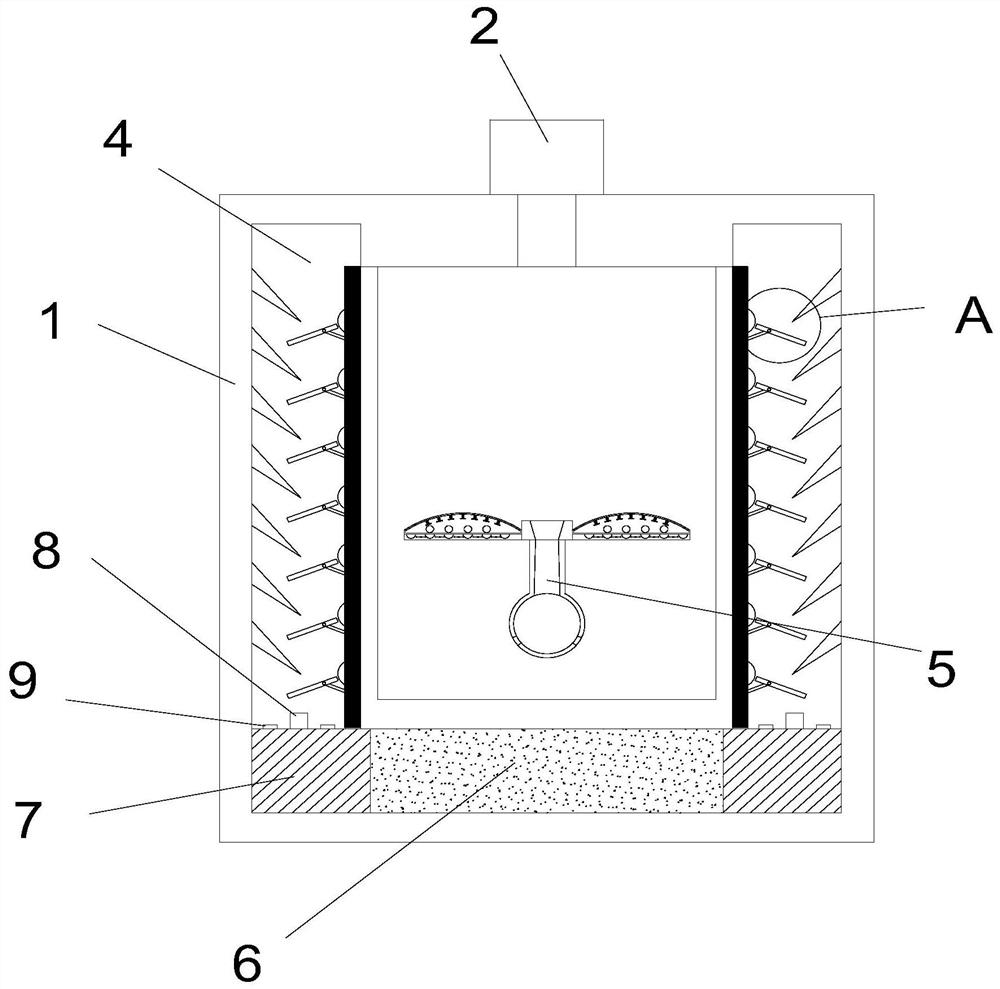

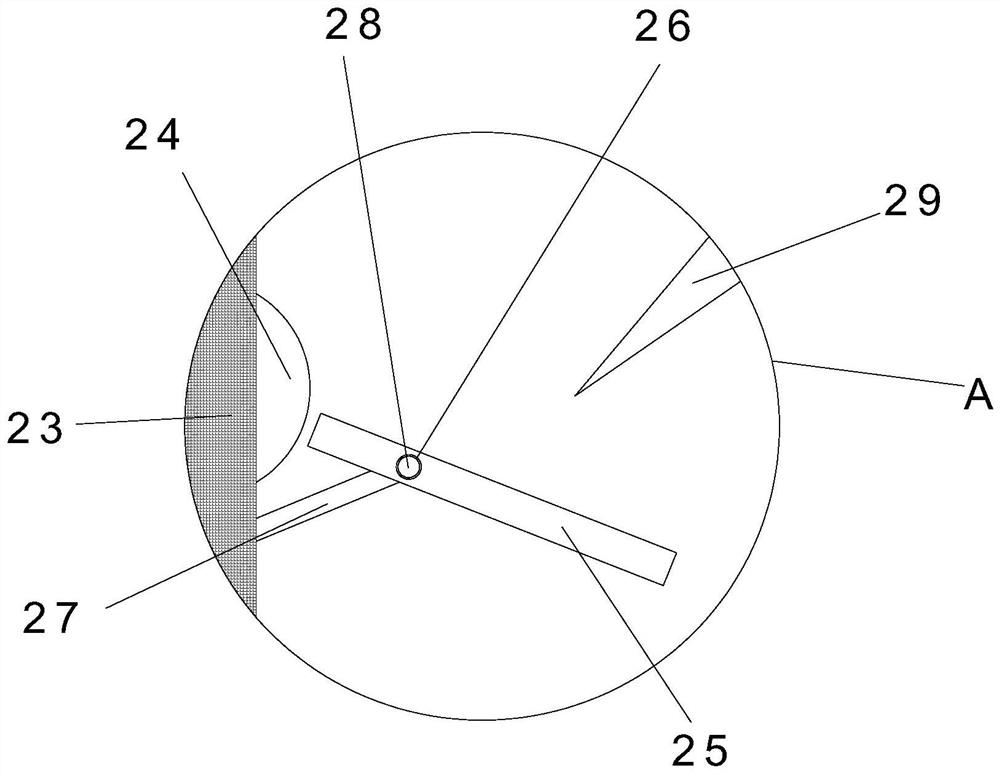

Catkin solidifying mechanical arm for municipal engineering and solidifying method

ActiveCN110184975ANon-flying phenomenonGood and thorough governanceRoad cleaningLiquid spraying apparatusCatkinEngineering

The invention relates to catkin solidifying mechanical arm for municipal engineering and a solidifying method. The catkin solidifying mechanical arm for the municipal engineering comprises a lifting mechanism installed on a municipal vehicle, a telescopic mechanism hinged to the lifting mechanism and a plurality of spraying pieces installed on the telescopic mechanism, and the spraying pieces arefixed to an atomization mechanism at intervals along an annular structure; the spraying pieces are flexible pieces, an expansion body with a stable shape is formed when the spraying pieces are filledwith air, and a plurality of air holes and a plurality of spraying holes are formed in one sides of the spraying pieces at intervals in the axial direction; the spraying holes and the air holes are alternately distributed at intervals; and the spraying holes spray solutions to willow branches and leaves, and solution atomization forms circulation through air holes blowing matching.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Preparation method of visual antibacterial and anti-inflammatory dressing for bacterial infection wound treatment

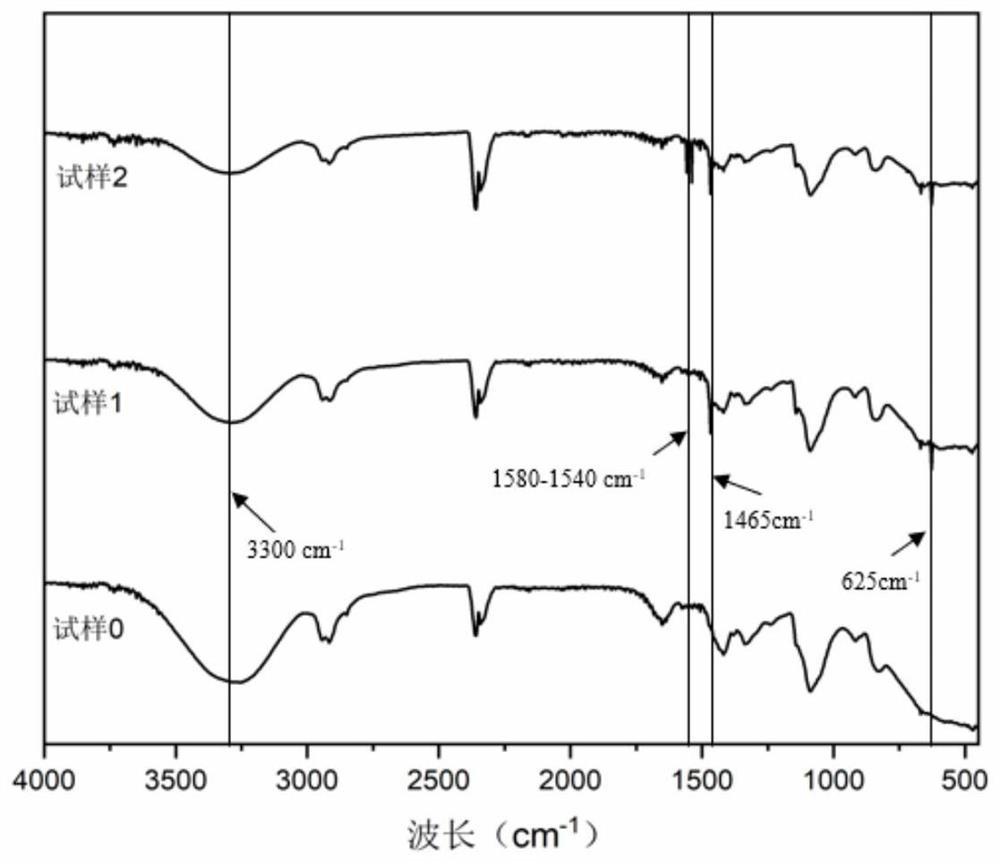

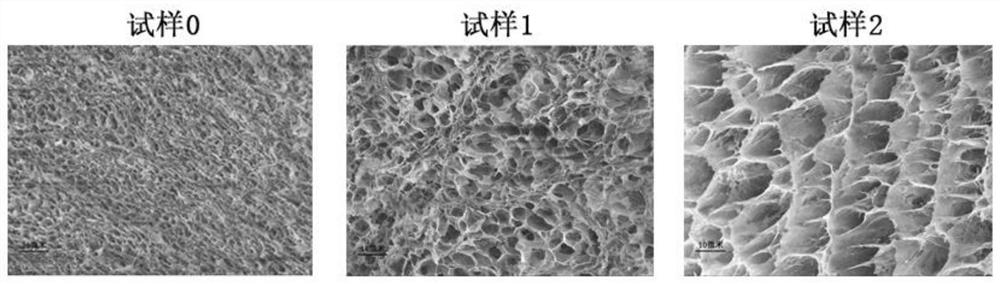

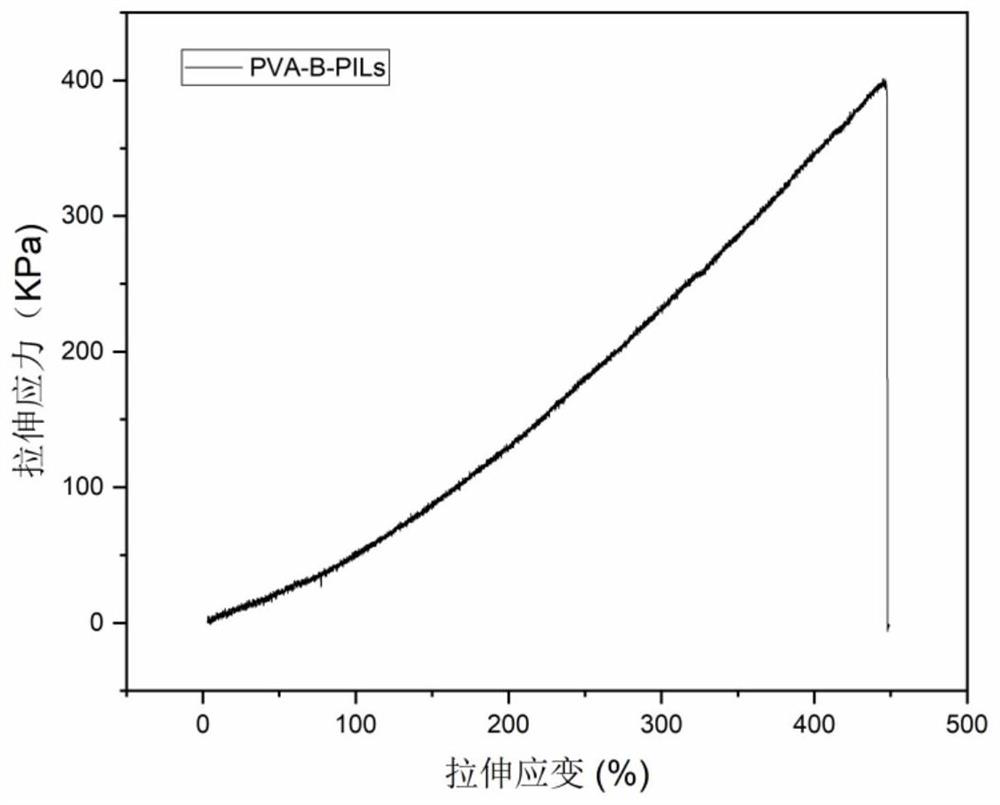

ActiveCN113813436BHigh light transmittanceGood antibacterial effectAbsorbent padsBandagesPolyvinyl alcoholEngineering

The invention discloses a preparation method of a visualized antibacterial and anti-inflammatory dressing for bacterial infection type wound treatment, comprising the following steps: step 1, dissolving polyvinyl alcohol and borax in water to obtain a mixed solution I; ‑Butylimidazolium bromide and ammonium persulfate are dissolved in water to obtain mixed solution II; step 3, nitrogen is introduced into mixed solution II; step 4, mixed solution II is subjected to a polymerization reaction after nitrogen is introduced to obtain a polyionic liquid Solution II; step 5, mixing the mixed solution I with the polyionic liquid solution II to obtain a dressing preparation solution; step 6, pouring the dressing preparation solution into a mold, and performing cyclic low-temperature freezing treatment to obtain a visualized antibacterial and anti-inflammatory dressing. The visualized antibacterial and anti-inflammatory dressing prepared by the method has the advantages of high light transmittance, excellent antibacterial performance and anti-inflammatory performance, good skin adhesion and self-healing performance, and has a good promoting effect on the healing of bacterial infection wounds. Features.

Owner:NORTHWEST UNIV

Chinese medicinal decoction for treating lithiasis

InactiveCN101590213BSymptoms lessen or disappearInfection controlDigestive systemPharmaceutical delivery mechanismTangerine PeelLiquorices

The invention relates to Chinese medicinal decoction used for treating lithiasis and a preparation method thereof, and relates to Chinese medicinal decoction for treating biliary calculus and renal calculus diseases. Main components of the decoction comprise ophiorrhiza pumila, dandelion, rhizoma sparganii, zedoary, white paeony root, herba pyrrosiae, bupleurum, Szechuan lovage rhizome, peach kernel, radix curcumae, gizzard lining, curcuma, knotgrass, gardenia, dried old orange peel, immature tangerine peel, liquorice and the like. The Chinese medicinal decoction can effectively heal intrahepatic bile duct calculus after the gall bladder is extirpated and calcification and sand-like calculus in the kidney, and simultaneously can effectively promote choleresis, improve the self-healing function of the gall bladder, and recover the functions of the gall bladder and the kidney.

Owner:吕文华

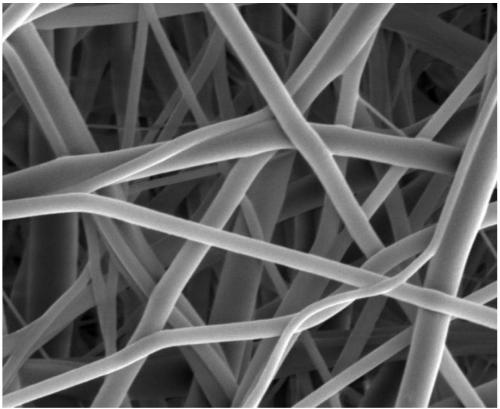

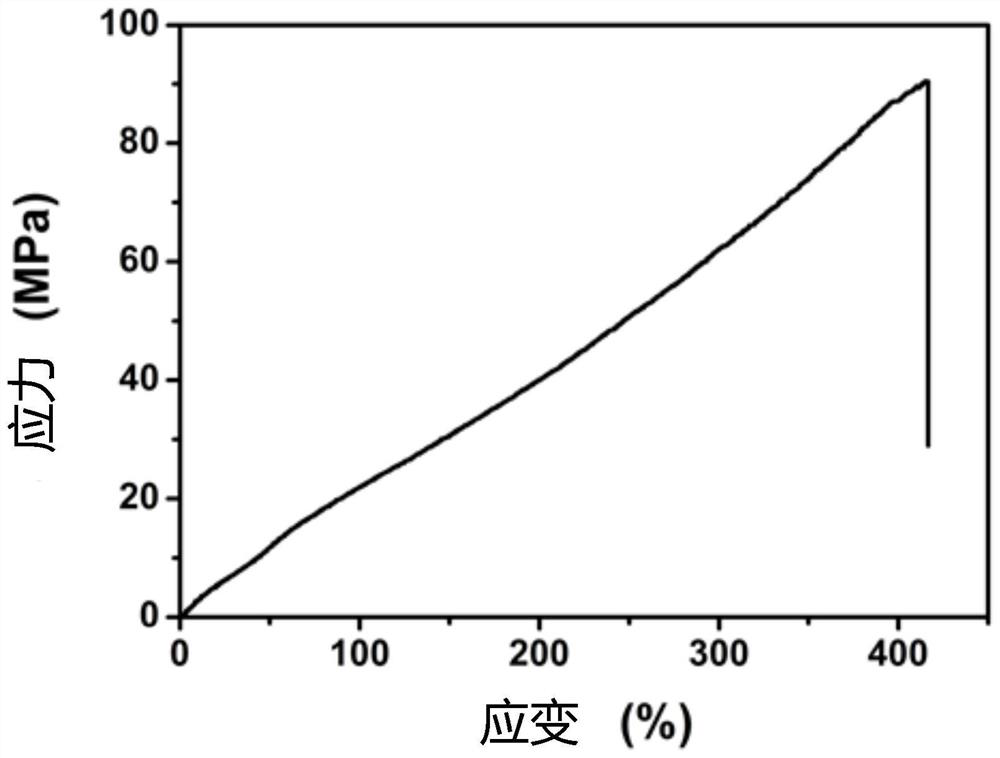

Nanofiber-reinforced absorbable intraosseous fixation material and preparation method thereof

ActiveCN112451753AHigh porosityStrong modifiabilitySurgeryElectro-spinningInternal bone fixationMedicine

The invention provides a nanofiber-reinforced absorbable intraosseous fixation material and a preparation method thereof. The nanofiber-reinforced absorbable intraosseous fixation material is mainly formed by compounding a biodegradable polymer material, nanofibers and an artificial bone material, wherein the surfaces of the nanofibers are modified; the content of the nanofibers accounts for 10-20% of the total weight of the material; the content of the biodegradable polymer material accounts for 60-80% of the total weight of the material; and the artificial bone material accounts for 10-20% of the total weight of the material. The nanofiber-reinforced absorbable intraosseous fixation material disclosed by the invention overcomes the defect that a common intraosseous fixation material is prone to multi-scale fracture; the nanofibers have the characteristics of large specific surface, high porosity, strong modification capability and high elastic modulus; the mechanical properties of the absorbable intraosseous fixation material is greatly improved; meanwhile, bone absorption and bone ingrowth are also further promoted; and the postoperative recovery process is accelerated.

Owner:STAR SPORTS MEDICINE CO LTD

A kind of willow catkin curing mechanical arm and curing method for municipal engineering

ActiveCN110184975BNon-flying phenomenonGood and thorough governanceRoad cleaningLiquid spraying apparatusStructural engineeringMechanical engineering

The invention relates to a mechanical arm for curing catkins used in municipal engineering and a curing method, comprising: a lifting mechanism installed on a municipal vehicle, a telescopic mechanism hinged on the lifting mechanism, and a plurality of spraying parts installed on the telescopic mechanism. The spraying part is fixed on the atomizing mechanism at intervals along the annular structure; the spraying part is a flexible part, and when the inside of the spraying part is filled with air, it forms a stable expansion body, and one side of the spraying part is arranged at intervals along the axial direction. A number of air holes and a plurality of spray holes; several spray holes and a number of air holes are alternately distributed; the spray holes spray the solution to the willow branches and leaves, and the air blowing through the air holes cooperates to make the solution spray form a circulation.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

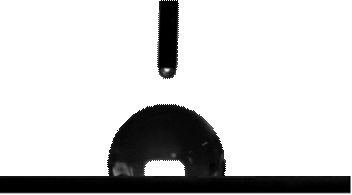

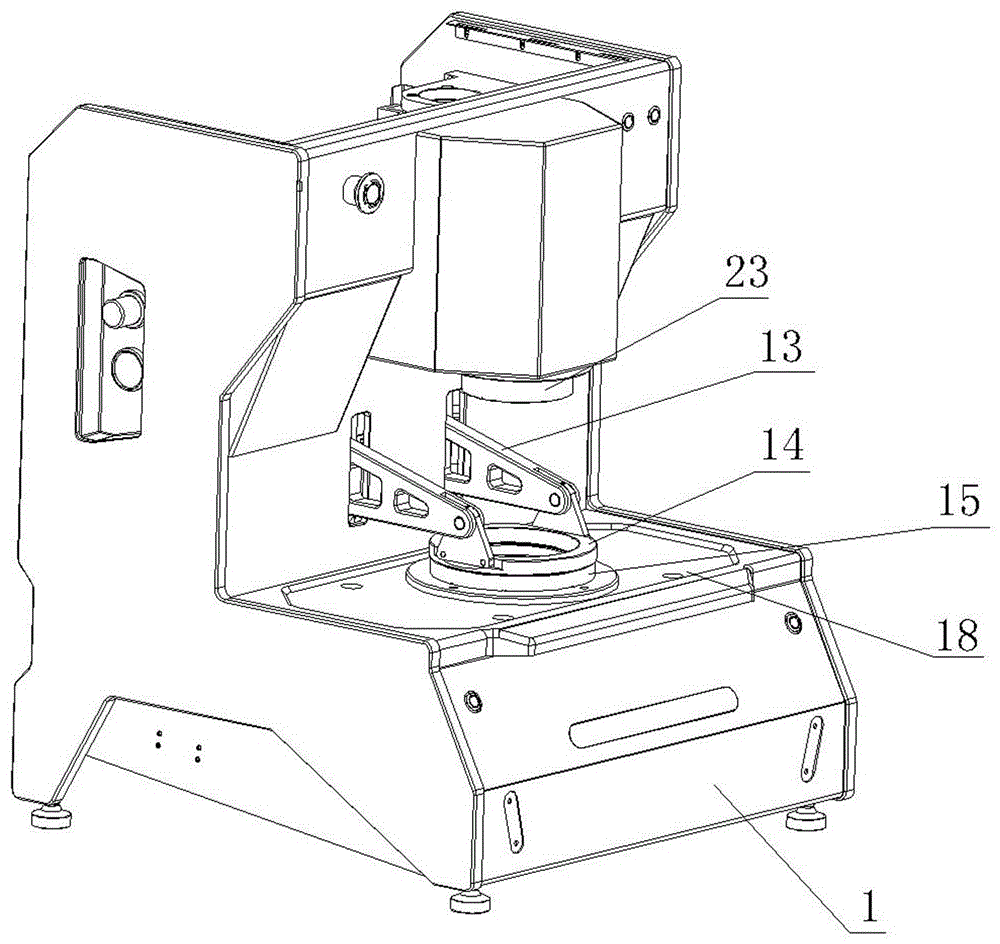

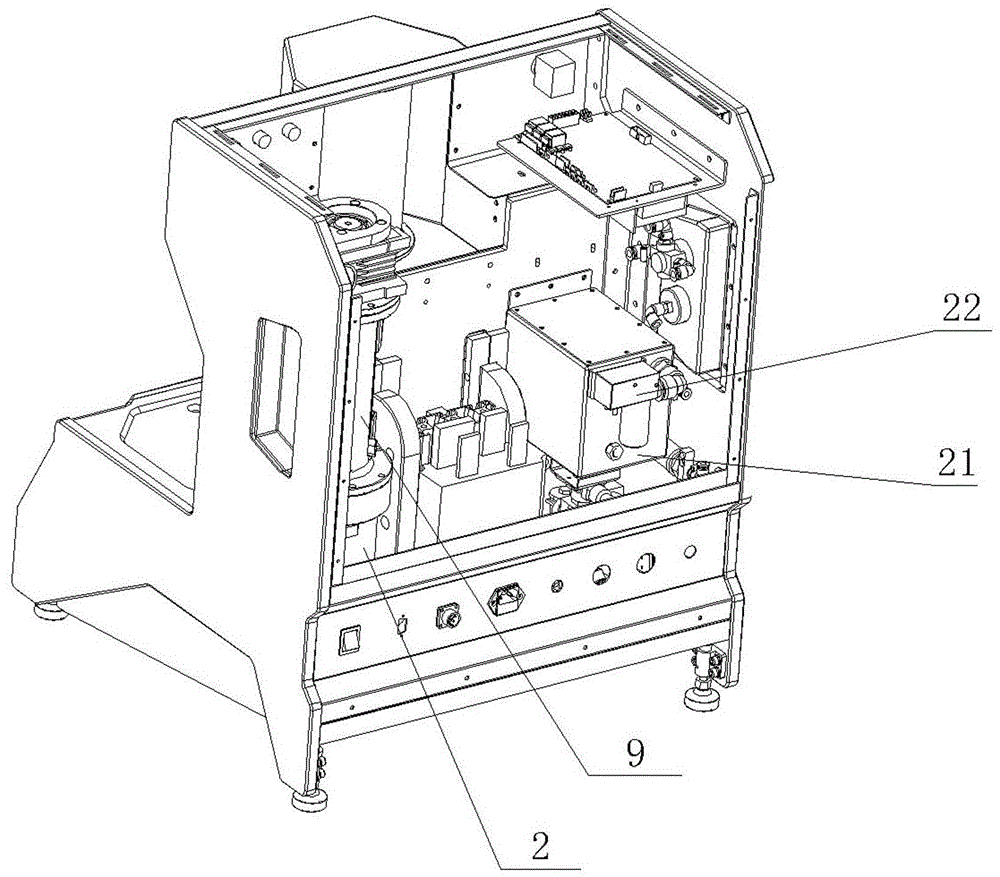

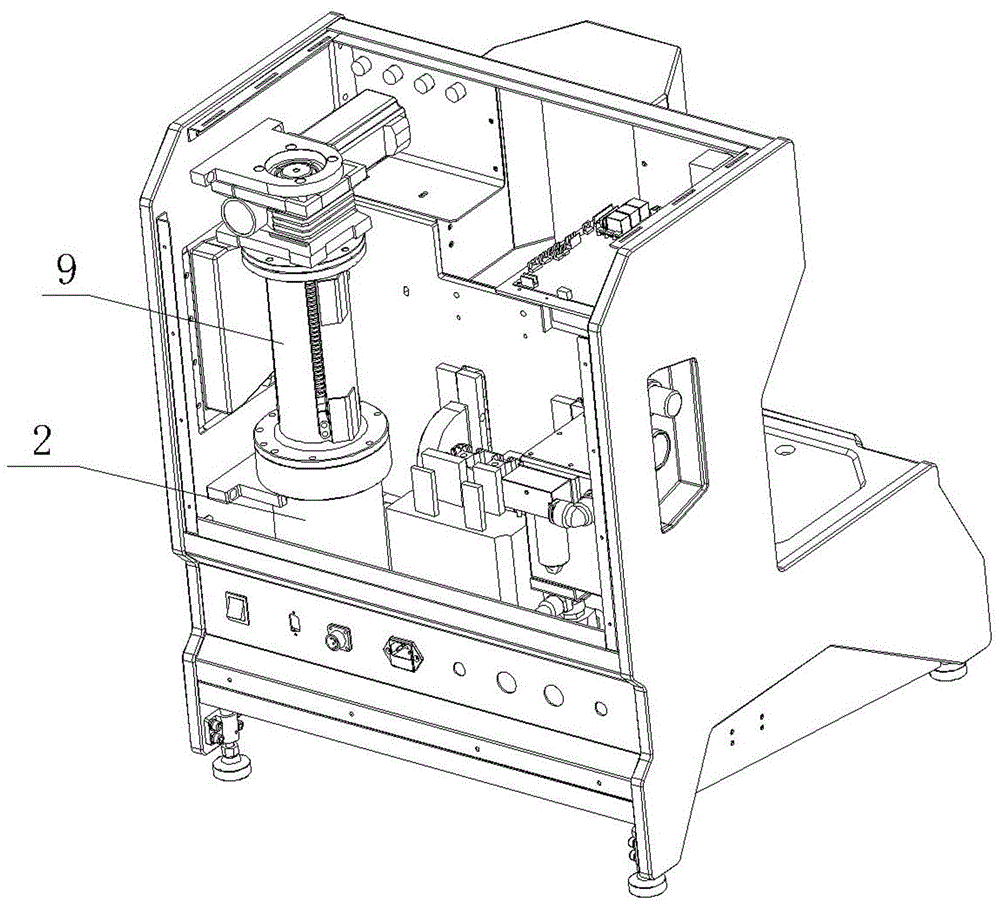

Fabric hydrostatic pressure test system and control method thereof

PendingCN106680183AAccurate recordReduce work stressPermeability/surface area analysisHydrostatic pressurePore water pressure

The invention discloses a fabric hydrostatic pressure test system. The fabric hydrostatic pressure test system comprises a frame, wherein the frame is provided with a fabric clamping assembly, a water supplying assembly, a water pressure adjusting assembly, an imaging assembly and a controller; the fabric clamping assembly is used for clamping a sample to be tested; an enclosed water groove is formed between the sample to be tested and the fabric clamping assembly; the water supplying assembly is used for supplying water to the enclosed water groove; the water pressure adjusting assembly is connected to a pipeline on the water supplying assembly; the water pressure adjusting assembly is used for adjusting the water pressure of water supplied to the enclosed water groove; the imaging assembly is arranged above the fabric clamping assembly; the imaging assembly is used for monitoring the condition of the surface of the sample to be tested; control circuits of the fabric clamping assembly, the water supplying assembly, the water pressure adjusting assembly and the imaging assembly are connected with a control circuit of the controller. The test system can be used for automatically judging the condition of the surface of the sample to be tested, so that the workload of test staff is relieved, and the condition of the surface of the sample to be tested can be recorded accurately.

Owner:NINGBO ZHONGWU DONGFANG OPTOELECTRONICS TECH CO LTD +1

A nanofiber-reinforced absorbable bone internal fixation material and its preparation method

ActiveCN112451753BHigh porosityStrong modifiabilitySurgeryElectro-spinningInternal bone fixationNanofiber

The invention provides a nanofiber-reinforced absorbable bone internal fixation material and a preparation method thereof. The nanofiber-reinforced bone internal fixation material is mainly composed of biodegradable polymer materials, nanofibers and artificial bone materials; wherein the surface of the nanofibers is modified or modified, and the content of the nanofibers accounts for 1% of the material. 10-20% of the total weight; the content of the biodegradable polymer material accounts for 60-80% of the total weight of the material; the artificial bone material accounts for 10-20% of the total weight of the material. The nanofiber-reinforced absorbable bone internal fixation material of the present invention overcomes the multi-scale fracture characteristics of common bone internal fixation materials; the nanofiber has the characteristics of large specific surface area, high porosity, strong modification ability and high elastic modulus, which greatly improves Improve the mechanical properties of absorbable bone internal fixation materials, and at the same time further promote bone resorption and bone ingrowth, and speed up postoperative recovery.

Owner:STAR SPORTS MEDICINE CO LTD

A kind of polyethersulfone microfiltration membrane and preparation method thereof

ActiveCN104525004BDiffusion slowLimit formationSemi-permeable membranesFiltration membraneOrganic solvent

The invention provides a preparation method of a polyether sulfone micro-filtration membrane. The preparation method includes the following steps that polyether sulfone and an additive are dissolved in an organic solvent, so that a casting solution is acquired; after membrane scraping is conducted on the casting solution, the casting solution is solidified in a coagulating bath of the liquid organic solvent and water, so that a wet membrane is acquired, wherein the liquid organic solvent is one or more of dimethylformamide, N-methyl pyrrolidone, dimethylacetamide, gamma-hydroxybutanoic acid and ethyl alcohol and the mass percentage concentration of the liquid organic solvent ranges from 5% to 40%; the wet membrane is dried in an aqueous solution containing a surface active agent, so that the polyether sulfone micro-filtration membrane is acquired. The aqueous solution containing the organic solvent is adopted for solidification, so that the sediment speed of the polyether sulfone in the coagulating bath is reduced, in other words, the membrane forming speed is reduced, membrane forming time is prolonged, large holes are prevented from being formed, formed membrane hole structures are uniform, the membrane flux is increased, and separation efficiency is high.

Owner:安得膜分离技术工程(北京)有限公司

A kind of micro-nano fiber reinforced concrete and preparation method thereof

ActiveCN109626881BImprove mechanical propertiesIncreased durabilityNanofiberFiber-reinforced concrete

The invention discloses micro-nano fiber reinforced concrete. The concrete comprises micro fiber with the surface provided with a first hydrophilic group and nano-fiber with the surface provided witha second hydrophilic group, wherein the content of the micro fiber in the concrete is set to be 2-5%, and the content of the nano-fiber in the concrete is set to be 5-10%. The nano fiber thins thick holes by filling hole structures between cement hydration products, the hole structure in the concrete is improved, the microstructure of the concrete is more compact, and harmful hole formation is effectively limited. The reinforced concrete obtained by blending the micro fiber, the nano-fiber and cement overcomes the characteristic of multiscale fracture, the nano-fiber and the micro fiber whichhave the surfaces provided with the hydrophilic groups and have the high elastic modulus greatly improve the mechanical property of the concrete, by adding additives, the mechanical property and the durability of the concrete are further enhanced, and the micro-nano fiber reinforced concrete with high bending resistance, high strength and high toughness is obtained.

Owner:UNIV OF SCI & TECH BEIJING

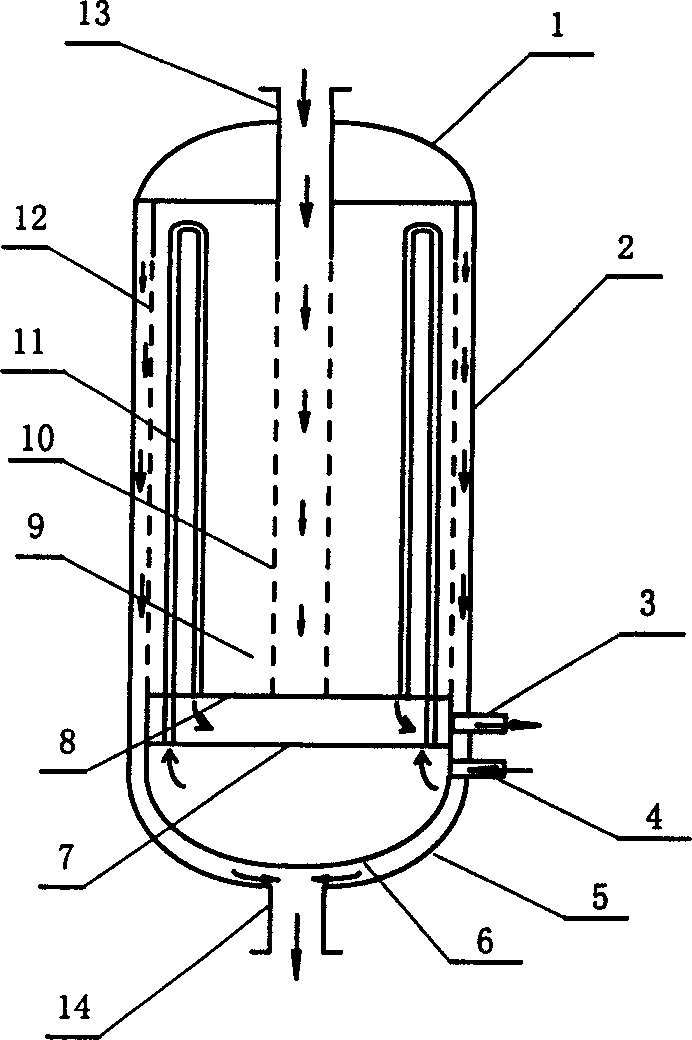

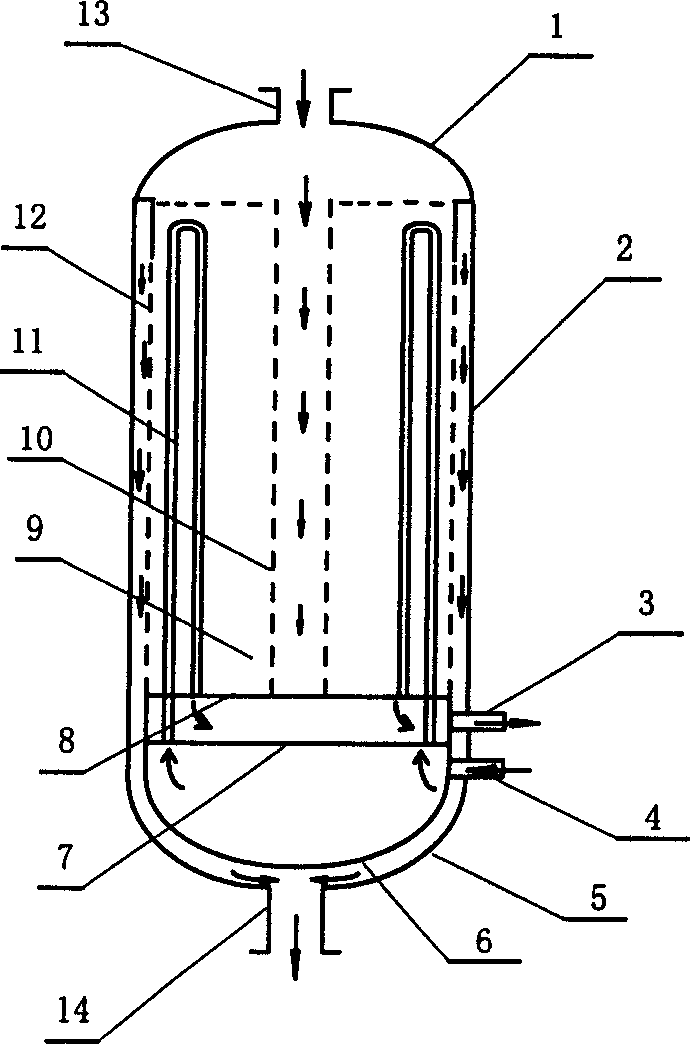

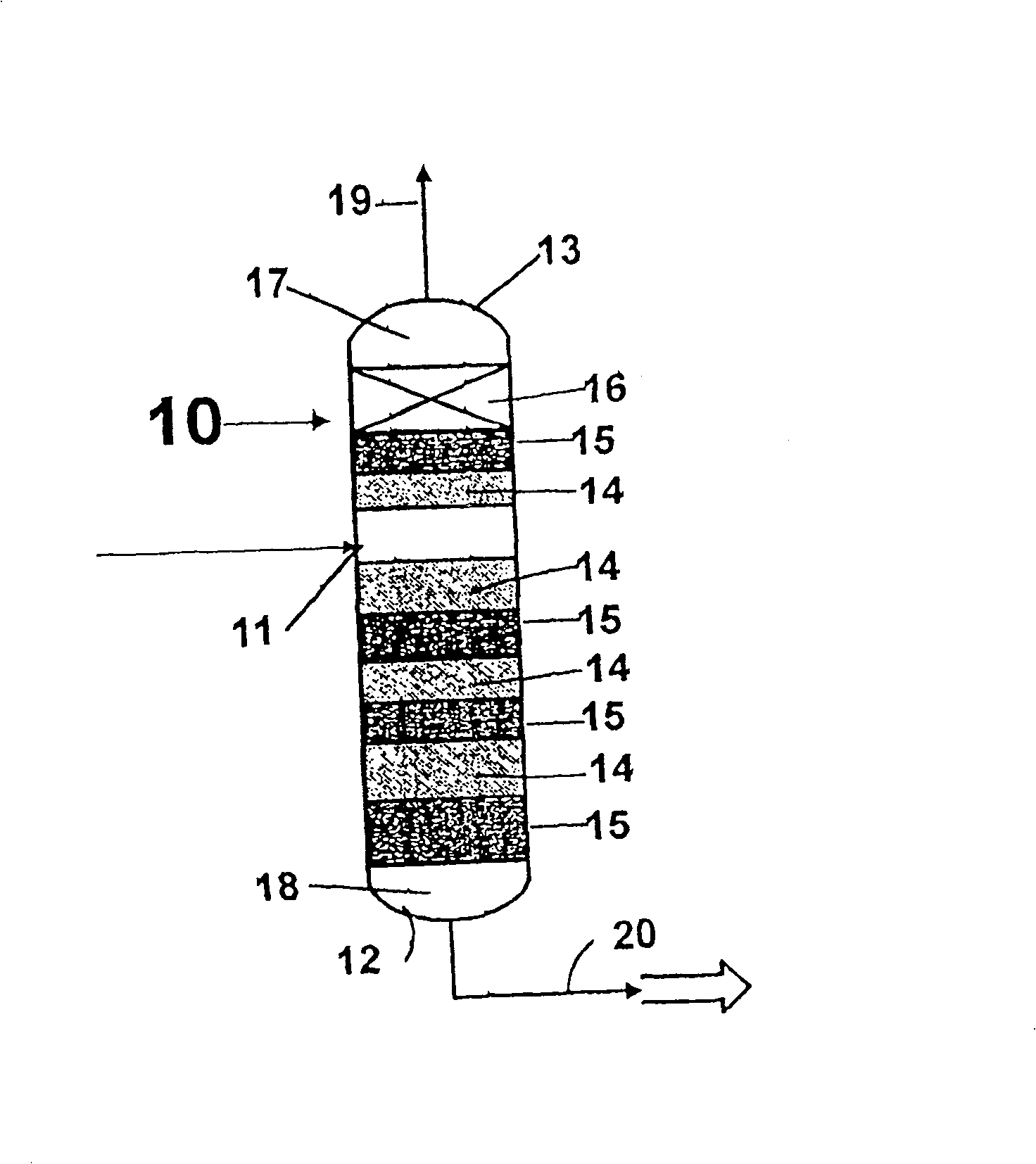

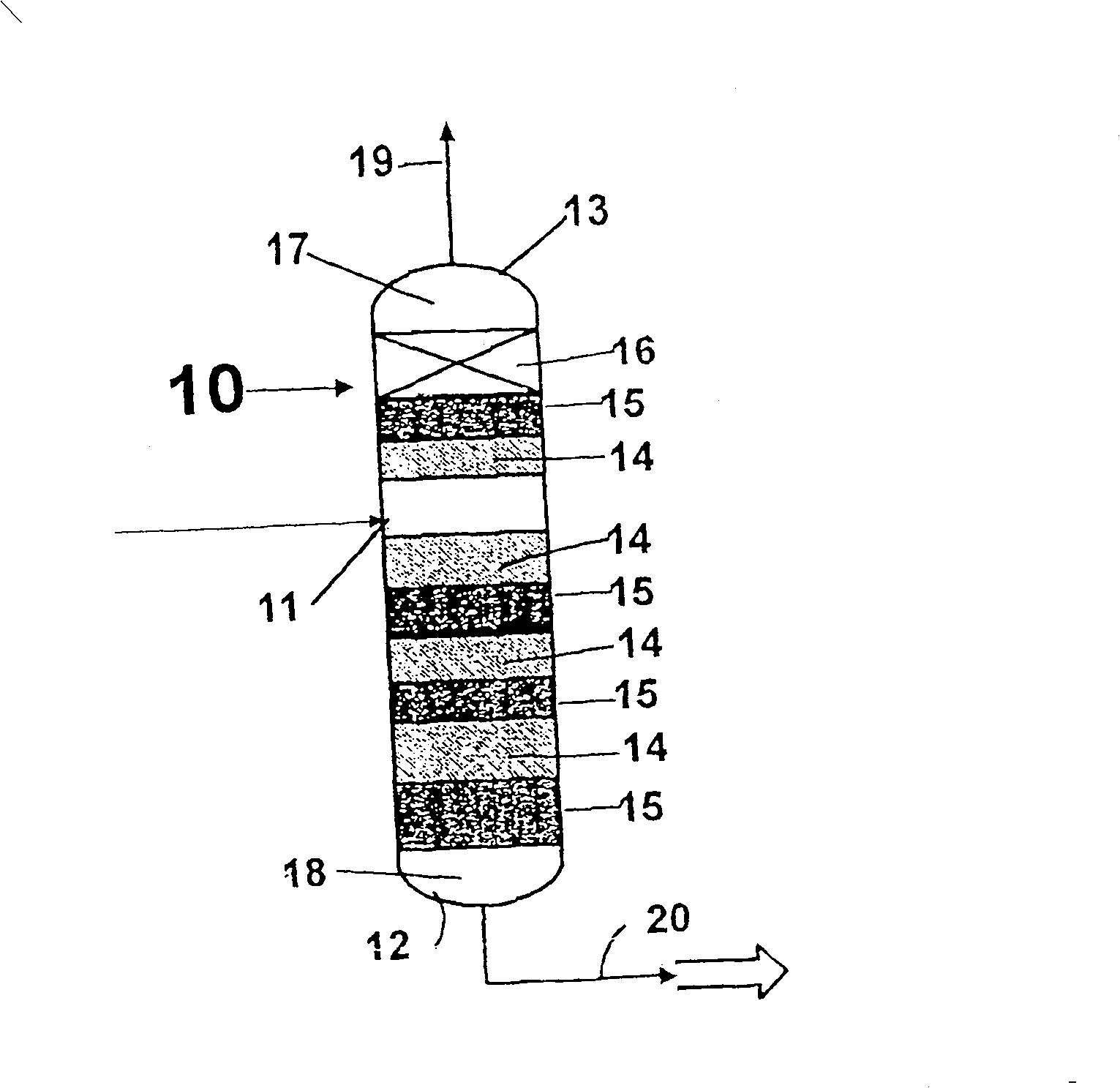

Method for producing styrene by catalytic dehydrogenation

InactiveCN1194948CLimit formationImprove conversion rateHydrocarbonsHydrocarbon preparationFixed bedDehydrogenation

The present invention relates to a method for producing styrene by catalytic dehydrogenation of ethylbenzene, the first stage of the steam is used for heating reactant effluent, then it is used as diluting agent of ethylbenzene. Said invented method is aimed at mainly resolving the problem of that in the existent production method the excessive change of catalyst bed layer temperature in the heat-insulating bed reactor along the flowing direction of the reaction medium can affect the catalyst performance, reaction conversion rate and reaction yield. Said invention adopts the technical scheme of adding at least one heating pipe in reactor bed layer of fixed bed so as to better resolve said problem.

Owner:CHINA PETROLEUM & CHEM CORP +2

Method for processing pure-natural and nuisance-free preserved eggs

The invention provides a raw material for processing preserved eggs. The processing raw material is composed of conventional raw materials and a core material, and the concrete ratios of formula raw materials are as follows: 20-50% of quicklime, 15-45% of sodium carbonate decahydrate, 1-15% of edible salt, and 15-45% of the core material. The invention also provides a method for processing preserved eggs, which comprises the following steps: preparation of egg products to be processed, selection of eggs, cleaning, draining, coating of pulp, plastering of the material, airtight curing, unsealing, airing with wind and aging, and packaging of finished products. The processing raw materials formula is adjusted, and yellow lead powder is not added, in order to produce lead-free products; coating of pulp and plastering of the material in the technique process change the traditional liquid state curing or raw material mud wrapped curing process, so that appropriate decomposition of amino acids is realized, and excess generation of sulfide is controlled. Storage life of the product is prolonged, and at the same time shape and flavour of the product are preserved perfectly. The airing with wind and aging process ensures promotion of the product mouthfeel and formation of exquisite appearance after shells are removed; aesthetic feeling and mouthfeel of the product are further improved, and the product is more beautiful and the taste is more delicious.

Owner:刘明友

Freeze-drying protective agent, fecal bacteria freeze-dried product and preparation method thereof

ActiveCN112195103BProtected SurvivalSpeed up the outflowMicroorganism preservationVitamin CFreeze-drying

The invention belongs to the field of microorganisms, and in particular relates to a freeze-drying protectant, a freeze-dried product of fecal bacteria and a preparation method thereof, the components of which include polydextrose, mannitol, glycine, vitamin C and Tween 80. The prepared freeze-dried fecal bacteria product has a high survival rate of total fecal bacteria, and the effect is better than that of trehalose, and can reduce the potential risks brought by trehalose and maltodextrin, and has the potential to improve the final quality of fecal bacteria transplantation products. curative effect.

Owner:SHENZHEN XBIOME BIOTECH CO LTD

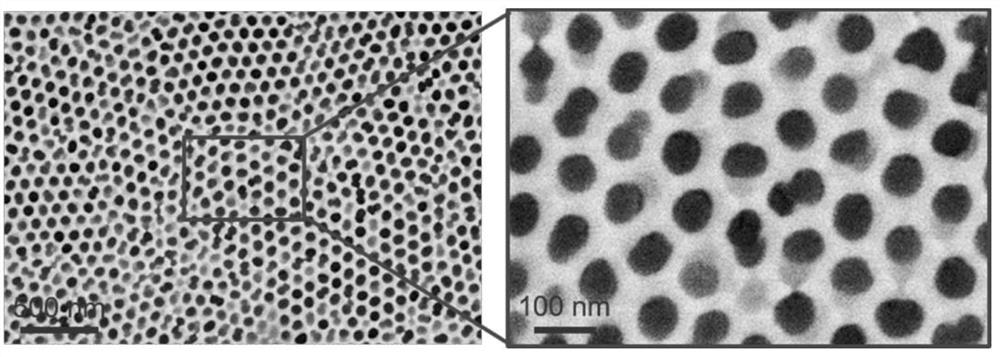

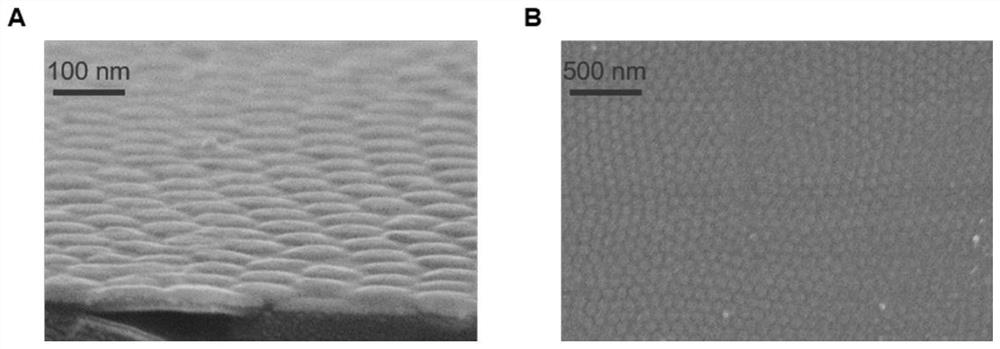

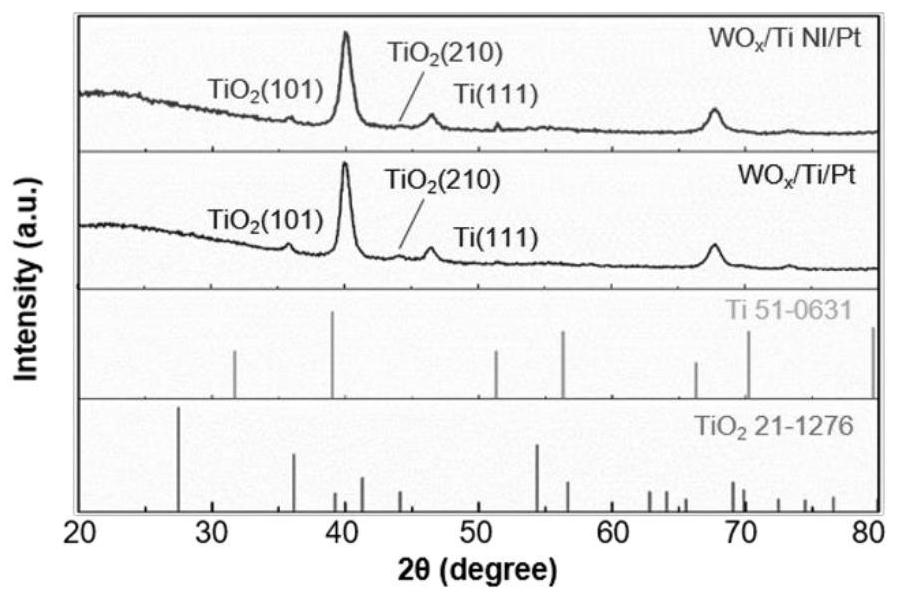

Tungsten oxide-based memristor embedded with Ti or Al nano island array and preparation method of tungsten oxide-based memristor

The invention discloses a preparation method of a tungsten oxide-based memristor embedded with a Ti or Al nano island array, which adopts a magnetron sputtering method, takes Pt metal as a target material, and deposits Pt with the thickness of 100nm as a bottom electrode. Ti or Al with the thickness of 5nm is deposited by adopting an electron beam evaporation method, and a highly ordered Ti or Al nano island array is prepared by virtue of an ultrathin AAO template. The average diameter of the Ti nano islands is 57.7 nm, and the average distance between centers of the islands is 100.2 nm. And WOx (x is equal to 2.2-2.5) with the thickness of 30nm is deposited by using a magnetron sputtering method and taking WOy (y is equal to 2.7-2.9) as a target material to prepare WOx / Ti NI / Pt and WOx / Al NI / Pt devices. The invention provides the preparation method of the tungsten oxide-based memristor embedded with the Ti or Al nano island array, the Forming (electroforming) process is avoided, the resistance change voltage dispersion is low, and compared with the photoetching technology, the cost is lower.

Owner:AFFILIATED HOSPITAL OF GUILIN MEDICAL UNIV +1

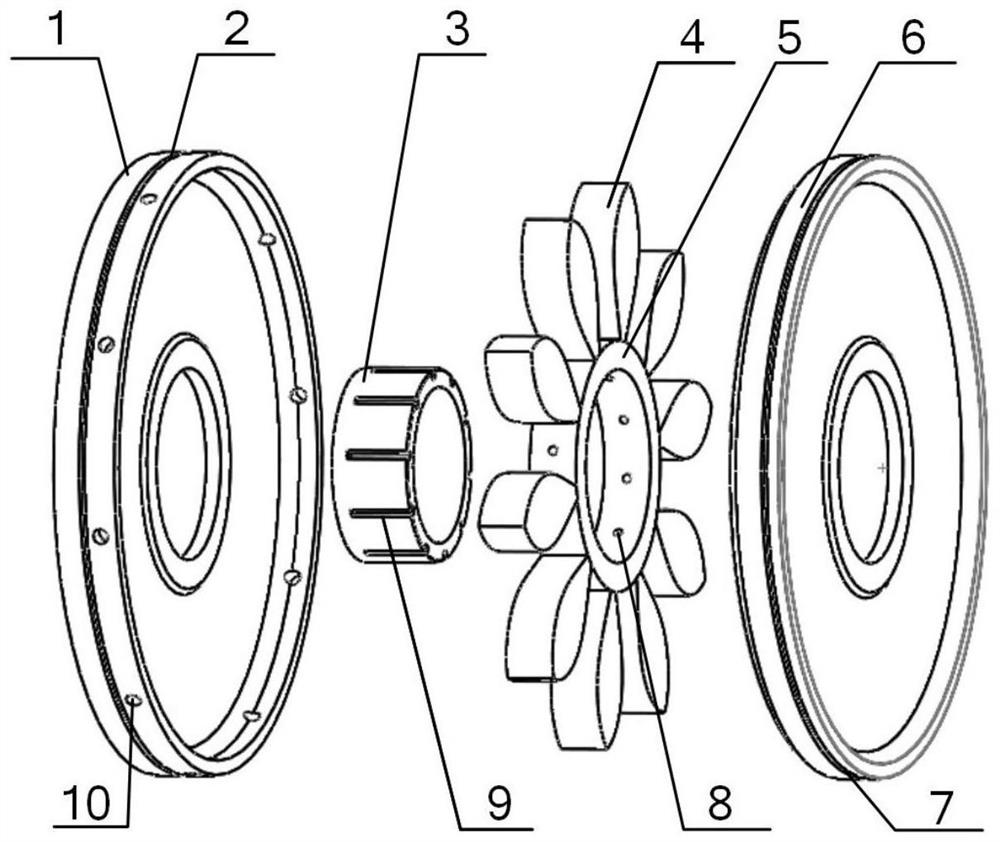

A spindle -shaped gas -like gas -like gas -like gas -like air system for the secondary air system of the gas turbine

ActiveCN113266599BGood strength and vibration performanceLow flow resistancePump componentsEfficient propulsion technologiesEngineeringBleed air

The present invention relates to a spindle-shaped air bleed structure used in a secondary air system of a gas turbine, comprising a two-stage rotor disk, a spindle-shaped bleed air structure and an air bleed disc. The two-stage rotor disc and the spindle-shaped air bleed structure are set on the air bleed disc. The air inlet hole on the rotor disc is facing the tip of the spindle-shaped air bleed block, and the air bleed hole on the spindle-shaped air bleed structure is directly on the air bleed disc. air duct. During operation, the main flow of fluid enters the disk cavity area through the air inlet holes on the first-stage rotor disk along the radial direction. Air flow in the disc cavity is guided by a spindle-shaped air bleed block through a tapered-expanded channel through the disc cavity area. Then the air flow enters the air outlet hole on the fixed plate along the radial direction, and the air outlet hole is facing the air induction groove on the air induction plate. The air flow turns in the direction of flow in the air duct and is drawn out in the axial direction. By selecting reasonable structural parameters, the bleed air structure is suitable for different working conditions. The present invention has the advantages of high efficiency, low resistance, compact structure, suitable for high rotation speed and the like, and has broad market prospects.

Owner:XI AN JIAOTONG UNIV

Non-dusting roll for tft glass

InactiveCN100526251CAvoid deformationOvercome limitationsGlass transportation apparatusRollersFiberGlass sheet

The present invention discloses a refractory roll cover that reduces the amount of harmful dust generated during the production of glass sheets. The roll cover has multiple segments including low dust hemp board segments that can be mechanically supported by highly hardened compressed fiber segments. The hemp sheet segments may be in contact with the glass sheet. The selection of this hemp sheet will make any dust generated have little affinity for the glass sheet or be easily fluidized by convection. Highly stiffened compressed fibers have a fused surface that releases little dust. The resulting roll covering is essentially capable of eliminating dust while also being a roll covering with good mechanical properties.

Owner:VESUVIUS CRUCIBLE CO

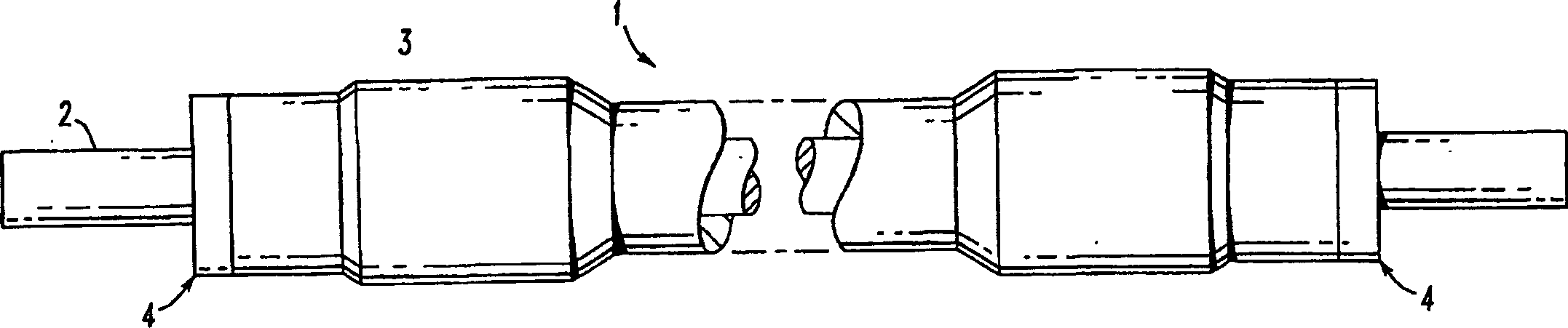

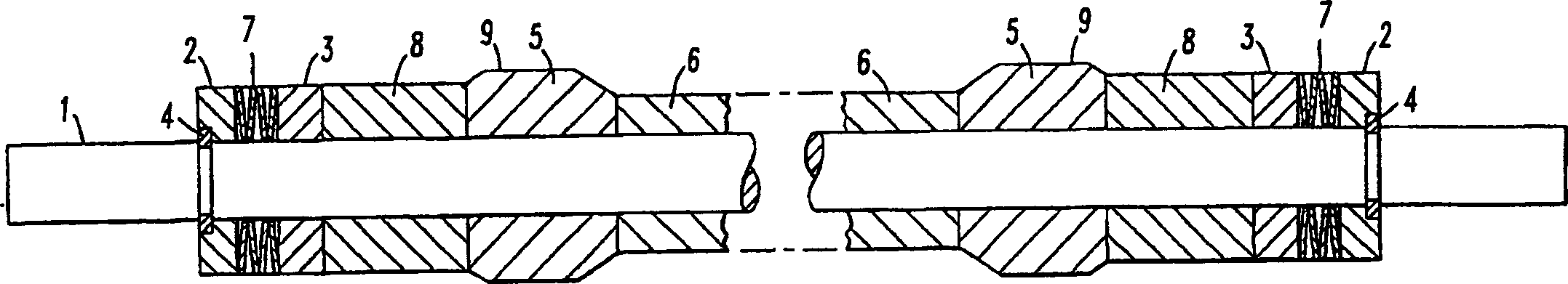

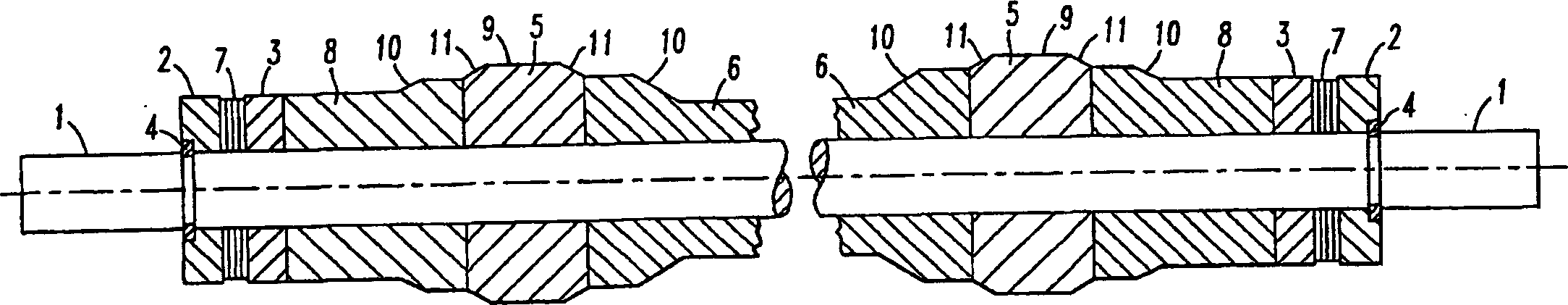

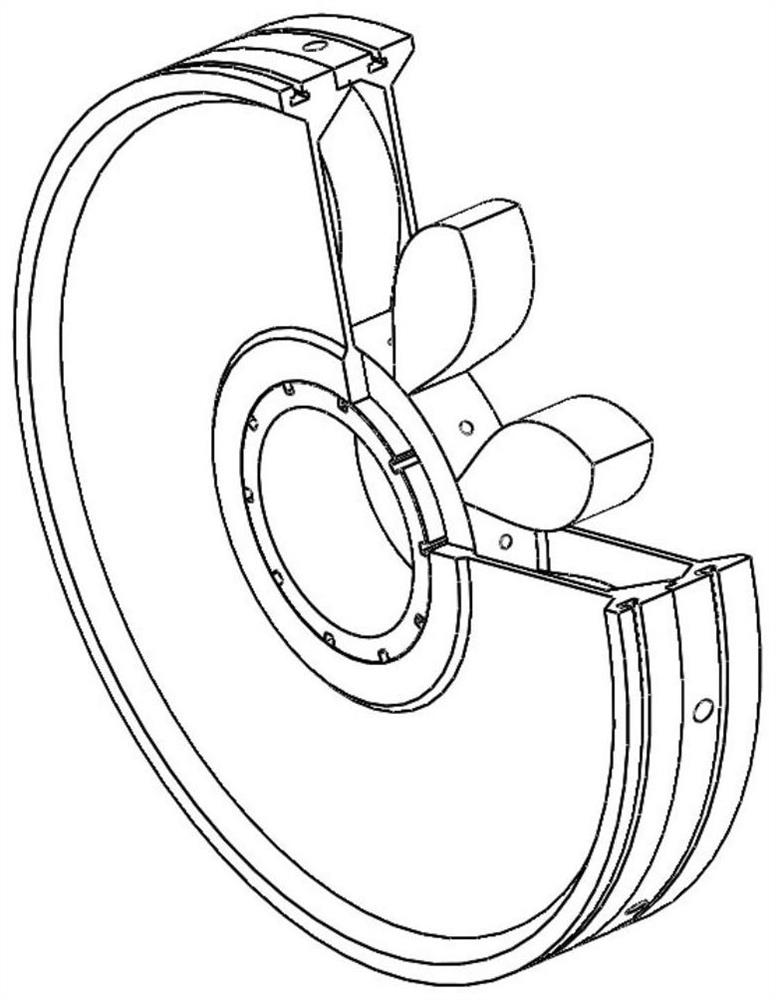

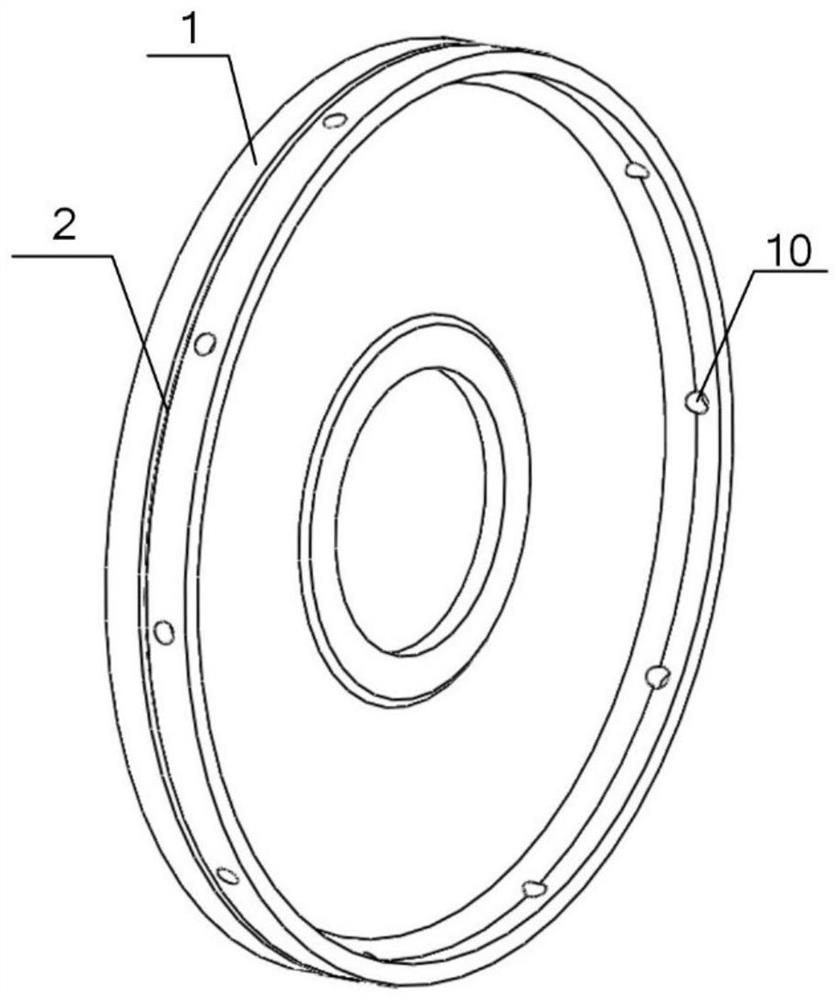

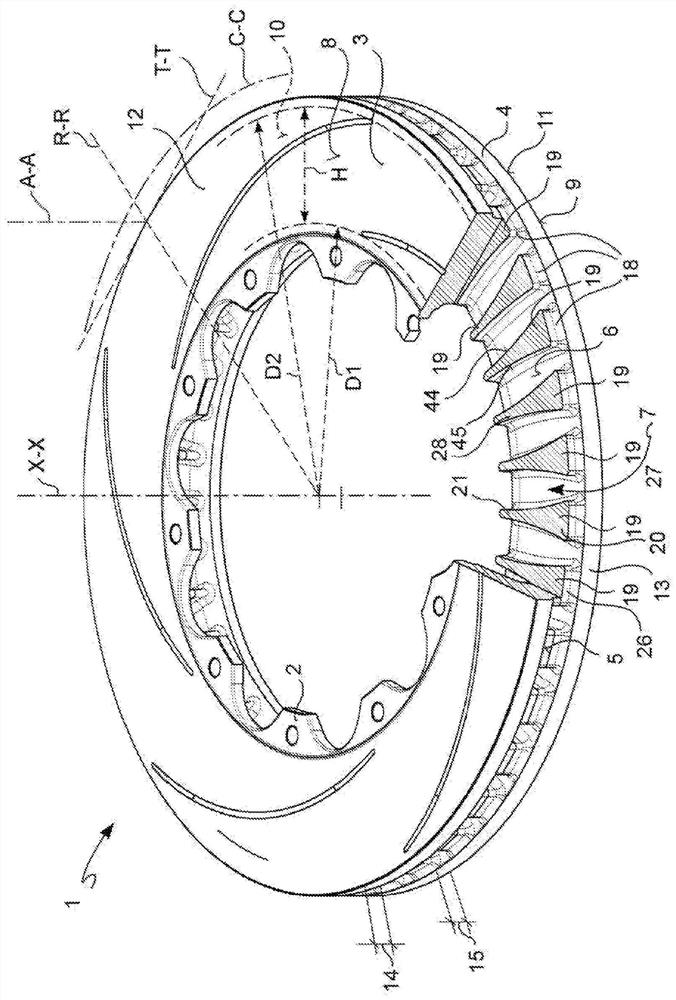

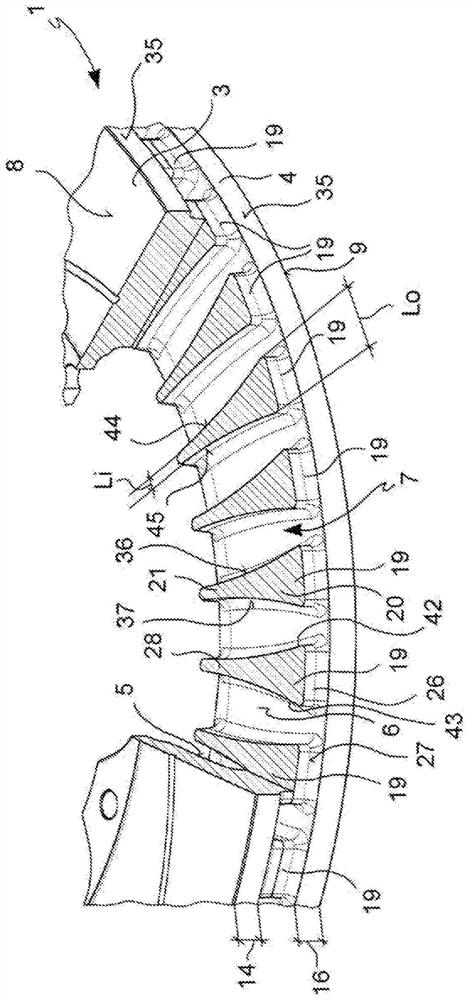

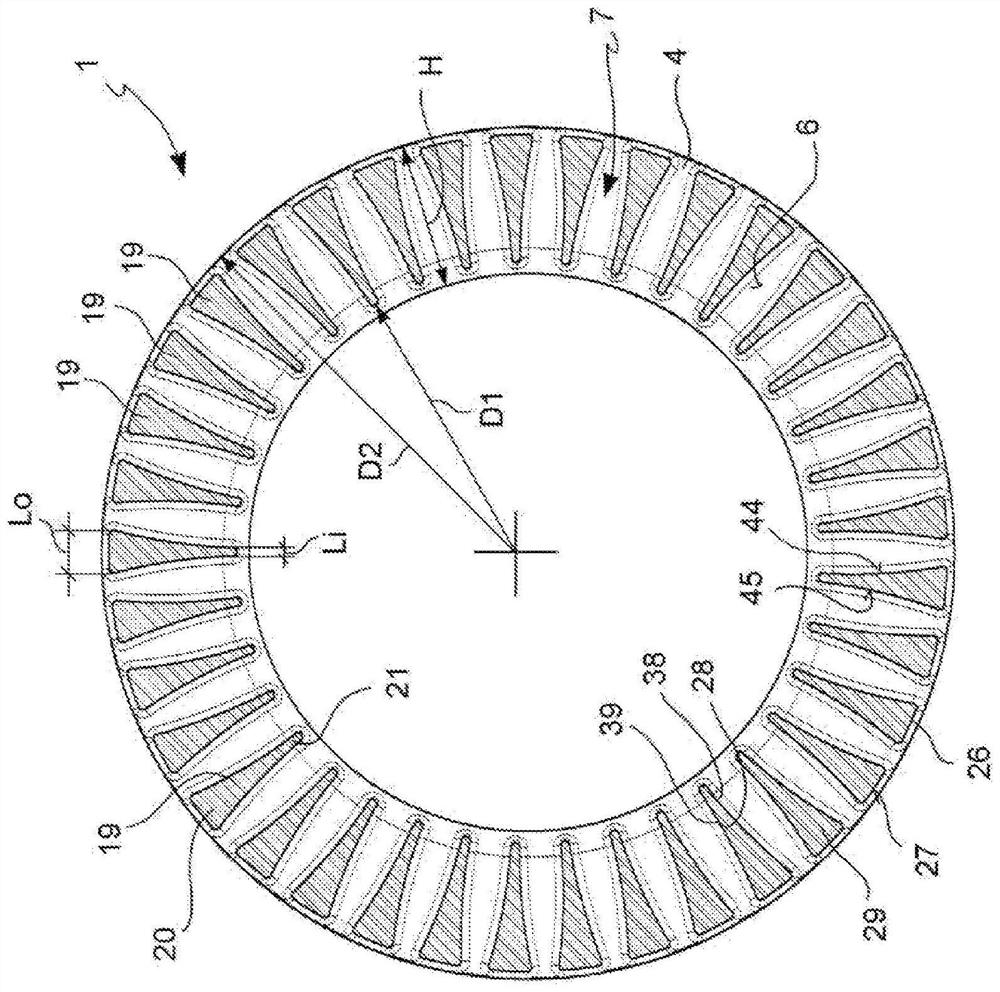

Brake band for disc of ventilated disc brake

PendingCN114641624AImproved Disk Cooling EfficiencyQuality improvementBraking discsRotational axisDisc brake

The invention relates to a brake band (1) for a disc (2) of a ventilated disc brake, in particular capable of avoiding vibrations that cause annoying screams during the braking action, said brake band (1) extending between an inner diameter (D1) near the axis of rotation (X-X) of the brake band (1) and an outer diameter (D2) remote from said axis of rotation (X-X), said inner diameter (D1) being adjacent to the axis of rotation (X-X) of the brake band (1) and the outer diameter (D2) being adjacent to the axis of rotation (X-X) of the brake band (1). The axis of rotation defines an axial direction (X-X); the brake band (1) comprises two plates (3, 4) facing each other; the plates (3, 4) comprise inner surfaces (5, 6) which directly or indirectly face each other and delimit a gap (7); said plates (3, 4) being joined to each other by means of heat-dissipating and connecting elements (16, 17, 19), also referred to as connecting elements; connecting elements (16, 17, 19) which protrude from the plates towards the opposite plates and touch the opposite plates so as to form bridges connecting the plates (3, 4) to each other; wherein a first group of fins (18) of the connecting elements are each a fin (19), which is in a single piece and extends from near the inner diameter portion (D1) to near the outer diameter portion (D2); and wherein each of the fins (19) of the first set of fins (18) comprises a fin outer end portion (20) located near the outer diameter portion (D1); a fin outer end portion (20) of the fin (19) comprises a predetermined extension in the outer circumferential direction, namely an outer circumferential width portion (Lo); the fin (19) comprises a fin inner end portion (21) located near the inner diameter (D1); a fin inner end portion (21) of the fin (19) including a predetermined extension in the inner circumferential direction, namely an inner circumferential width portion (Li); wherein the outer circumferential width portion (Lo) is larger than the inner circumferential width portion (Li) in a cross-section taken along a cross-section plane including a radial direction (R-R) and a circumferential direction (C-C) and determined to pass through an average air flow point traveling through the gap; and wherein the fin outer end portion (20) of each of the fins (19) of the first set of fins (18) faces only on both sides in the circumferential direction (C-C) adjacent fins (19) of the first set of fins (18).

Owner:FRENI BREMBO SPA

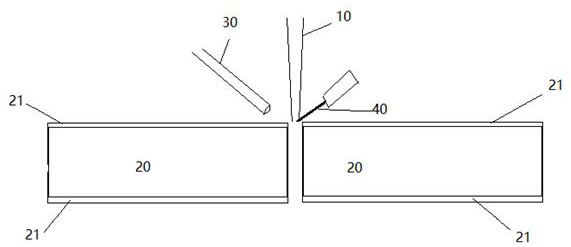

Split type high-order laser beam based tailor welding method for automotive aluminum-silicon coated steel plates

ActiveCN113560720AEliminate randomEliminate continuityLaser beam welding apparatusWeld seamTransverse mode

The invention discloses a split type high-order laser beam based tailor-welding method for automotive aluminum-silicon coated steel plates. The method comprises the following steps that 1, the two aluminum-silicon coated steel plates are fixed with a tailor-welding gap of 0.3-0.4 mm; and 2, in the protective gas atmosphere, split type high-order laser beam laser wire filling welding is adopted, a split type high-order laser beam is a high-order laguerre-gaussian transverse mode laser beam, and the order comprises TEM01, TEM02, TEM10, TEM20 and TEM30; a split type high-order laser beam spot comprises several high-energy areas and low-energy areas which are distributed in a staggered mode, a temperature gradient is formed during welding, metal flows from the high-energy areas to the low-energy areas in a high-speed staggered mode, a welding pool is stirred, and harmful elements are evenly distributed; and a welding wire contains N and Ni, and protective gas is argon, nitrogen and helium. According to the method, the split type high-order laser beam with special energy distribution is combined with the welding wire and a welding process, so that the distribution uniformity of aluminum elements in a welding seam is improved, and the welding quality is improved.

Owner:SHANGHAI BAOSTEEL & ARCELOR TAILOR METAL

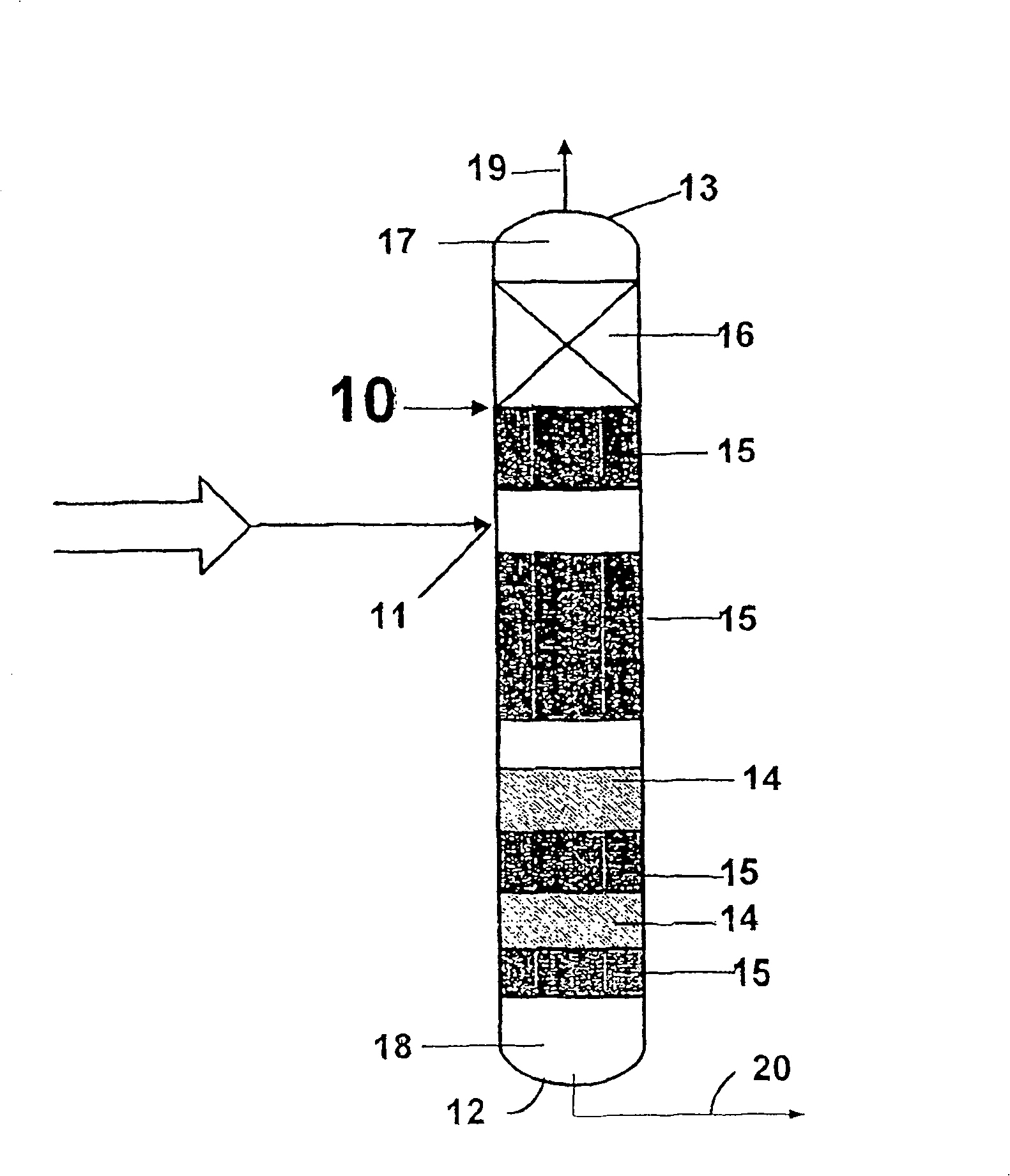

Process for improved yields of high molecular weight olefins form lower molecular weight olefines

InactiveCN100425582CIncrease productionLimit formationHydrocarbon by isomerisationOrganic chemistry methodsNarrow rangeIsomerization

A process for improved yields of heavier olefins from a substantially narrow range of lighter hydrocarbon feed stock containing olefins in a reaction distillation column comprising feeding a narrow range of hydrocarbon feed stock containing olefin into a reaction distillation column at a point between its bottom and top, contacting the olefins at the point of feed with a disproportionation catalyst in alternating arrangement with an isomerization catalyst or a mixture thereof and keeping the reaction mixture in a state of vapor-liquid equilibrium for concentrating the lighter reaction products in the vapor phase and the heavier reaction products in the liquid phase by maintaining a controlled pressure and temperature profile in the reactive distillation column and for reactively creating the desired heavier molecular weight olefins over the catalysts and collecting it as bottoms product and removing the lighter molecular weight olefins overhead from the top of the reactive distillation column.

Owner:阿门·纳扎·阿巴扎建

Improved method for etching vias

InactiveCN100345259CAvoid formingReduce formationElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringInductively coupled plasma

Owner:UNAXIS USA

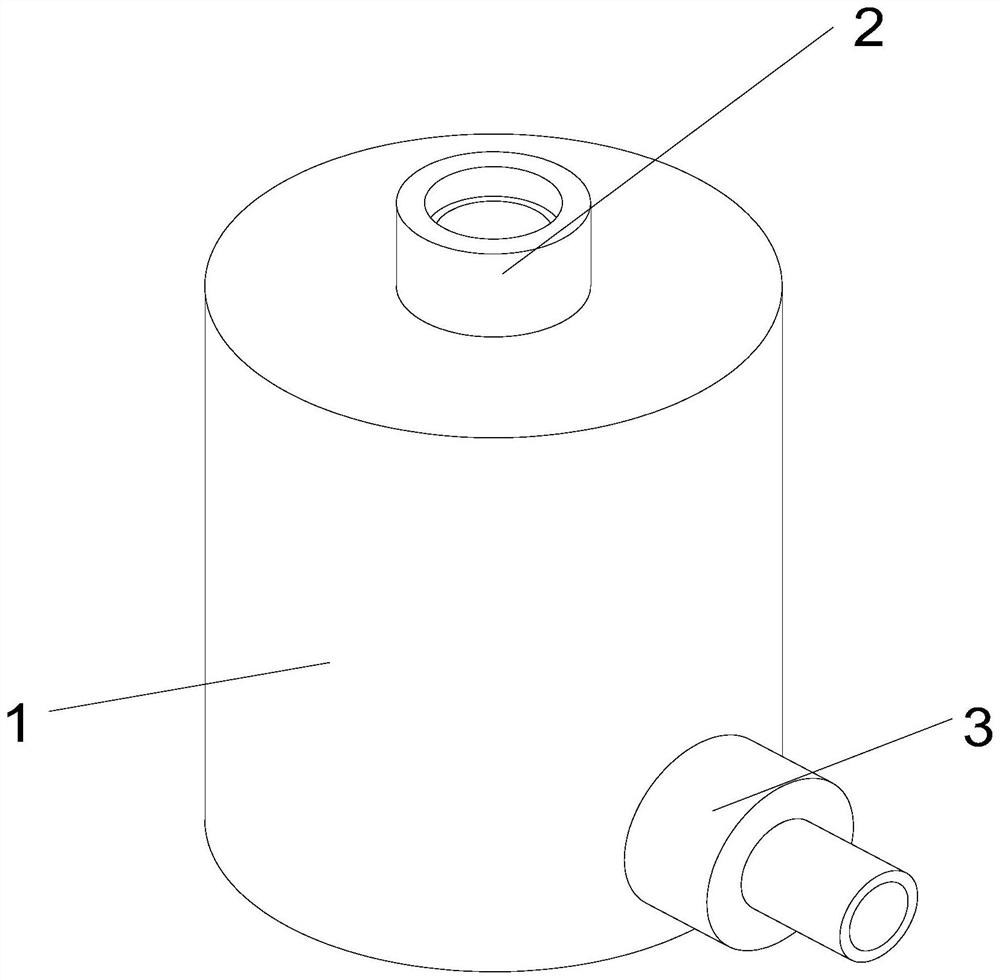

New energy automobile ethanol storage device and new energy automobile power system

PendingCN114851839AReduce shakingReduce unnecessary volatilizationDomestic cooling apparatusLighting and heating apparatusTemperature controlAlcohol ethyl

The invention discloses a new energy automobile ethyl alcohol storage device and a new energy automobile power system, and relates to the technical field of new energy automobiles, the new energy automobile ethyl alcohol storage device comprises a storage box, a feeding port is formed in the top of the storage box, and a conveying device is arranged on the front side wall face of the storage box; a U-shaped annular heat preservation groove is annularly formed in the side wall of the inner side of the storage box, and a constant temperature device capable of conducting appropriate temperature control on water in the heat preservation groove is arranged in the middle of the bottom of the heat preservation groove. An ethanol solution in the storage box vibrates in the storage box, when the ethanol solution sinks, the corresponding position on a deformation limiting plate deforms, meanwhile, folding auxiliary balls in folding auxiliary grooves in the deformation limiting plate are limited and influenced by gravity, and the deformation limiting plate is forcibly driven to conduct sectional type attaching deformation; and therefore, the situation that the ethanol shakes when the automobile bumps is reduced.

Owner:邸海东

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com