Split type high-order laser beam based tailor welding method for automotive aluminum-silicon coated steel plates

A coated steel plate and laser beam technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problem that the flow of harmful elements such as aluminum, sulfur, and phosphorus cannot be effectively controlled, the concentration of harmful elements cannot be effectively suppressed, and cannot be universal Application of various types of plates and other issues to achieve the effect of avoiding deterioration of weld performance, improving feasibility and versatility, and avoiding tensile fracture after hot pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

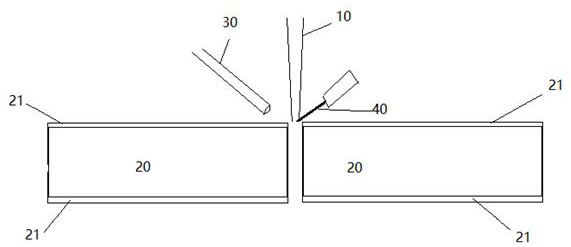

[0050] Please see attached figure 1 , Step 1: Fix two aluminum-silicon-coated steel plates 20 to be tailor-welded on the welding operation platform, which can be fixed by magnetic suction, and the tailor-welded gap between the two aluminum-silicon-coated steel plates 20 is 0.3mm. The thickness of the two aluminum-silicon-coated steel plates 20 is 2 mm, and the size is 300*300 mm. The thickness of the coating 21 on the upper and lower surfaces of the aluminum-silicon coated steel plate 20 is 25um, and the composition of the coating 21 is 90% Al, 5% Si, and the rest is iron in terms of mass percentage.

[0051] Step 2: Under the protective gas atmosphere, use the split-type high-order laser beam 10 to perform laser wire-fill welding on two aluminum-silicon-coated steel plates 20 through the welding wire 40. The split-type high-order laser beam 10 is a disc-type optical fiber in the prior art The laser generates a high-order Laguerre-Gaussian transverse mode laser beam with a po...

Embodiment 2

[0057] Please see attached figure 1 , Step 1: Fix two aluminum-silicon-coated steel plates to be tailor-welded on the welding operation platform, and the tailor-weld gap between the two aluminum-silicon-coated steel plates is 0.3mm. The thickness of the two aluminum-silicon-coated steel plates is both 2mm, and the size is 300*300mm. The thickness of the coating on the upper and lower surfaces of the aluminum-silicon coated steel plate is 25um, and the composition of the coating is 90% Al, 5% Si, and the rest is iron in terms of mass percentage.

[0058] Step 2: In a protective gas atmosphere, use a split high-order laser beam to perform laser wire-fill welding on two aluminum-silicon coated steel plates through a welding wire. The split high-order laser beam is the power generated by a disc-type fiber laser in the prior art 8KW high-order Laguerre-Gaussian transverse mode laser beam, the order is TEM02, as attached image 3 As shown, the wavelength is 1064 nm, the minimum ou...

Embodiment 3

[0064] Please see attached figure 1, Step 1: Fix two aluminum-silicon-coated steel plates 20 to be tailor-welded on the welding operation platform, which can be fixed by magnetic suction, and the tailor-welded gap between the two aluminum-silicon-coated steel plates 20 is 0.3mm. The thickness of the two aluminum-silicon-coated steel plates 20 is 2 mm, and the size is 300*300 mm. The thickness of the coating 21 on the upper and lower surfaces of the aluminum-silicon coated steel plate 20 is 25um, and the composition of the coating 21 is 90% Al, 5% Si, and the rest is iron in terms of mass percentage.

[0065] Step 2: Under the protective gas atmosphere, use the split-type high-order laser beam 10 to perform laser wire-fill welding on two aluminum-silicon-coated steel plates 20 through the welding wire 40. The split-type high-order laser beam 10 is a disc-type optical fiber in the prior art The laser generates a high-order Laguerre-Gaussian transverse mode laser beam with a pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com