Radio frequency interface circuit

A radio frequency interface and circuit technology, applied in circuit devices, printed circuits, printed circuit components, etc., can solve the problems of difficult to meet the mounting and drag welding methods, increased insertion loss, large standing wave ratio, etc. Ultra-wideband impedance matching, miniaturization, and the effect of reducing high frequency VSWR and insertion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

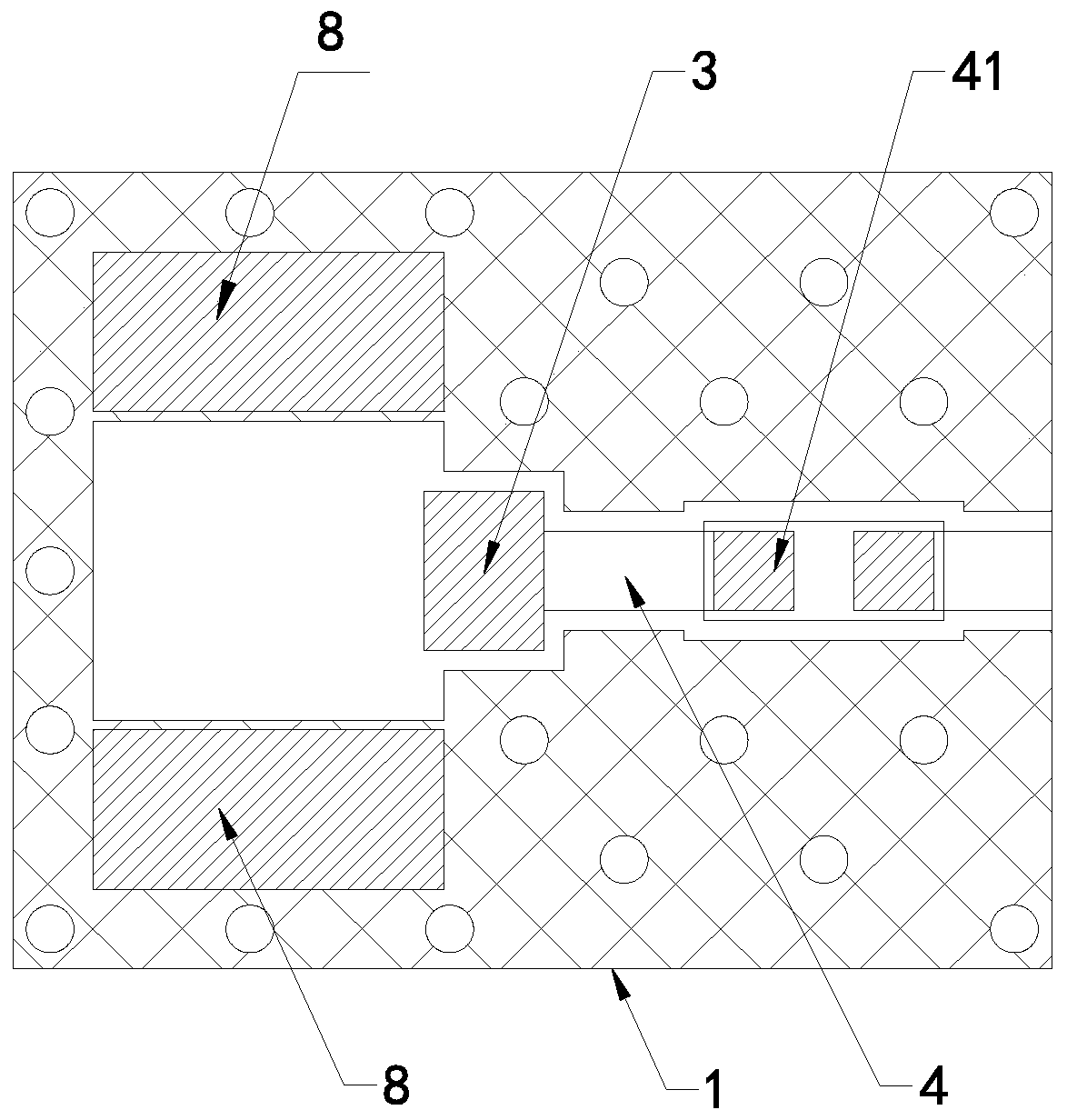

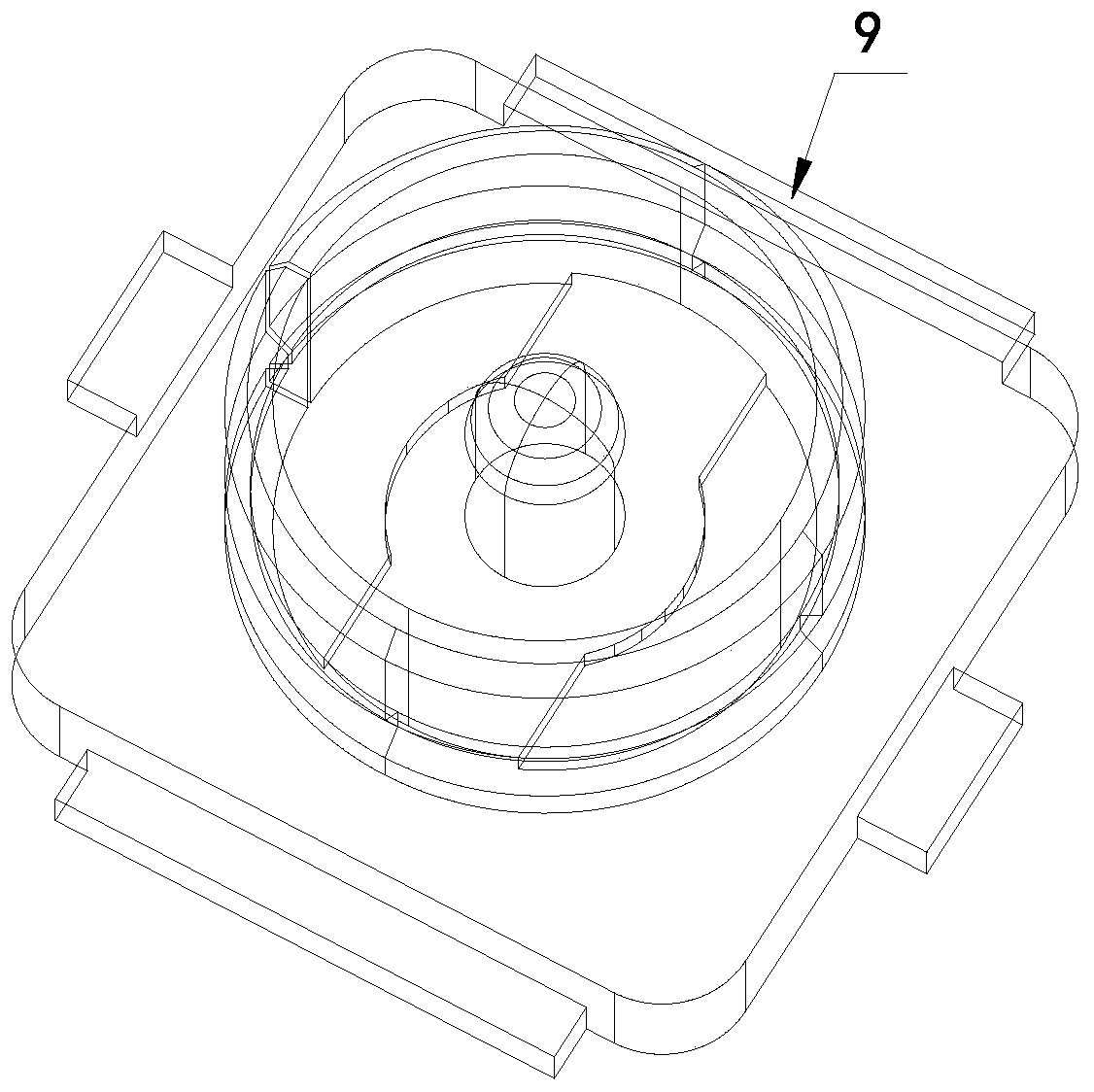

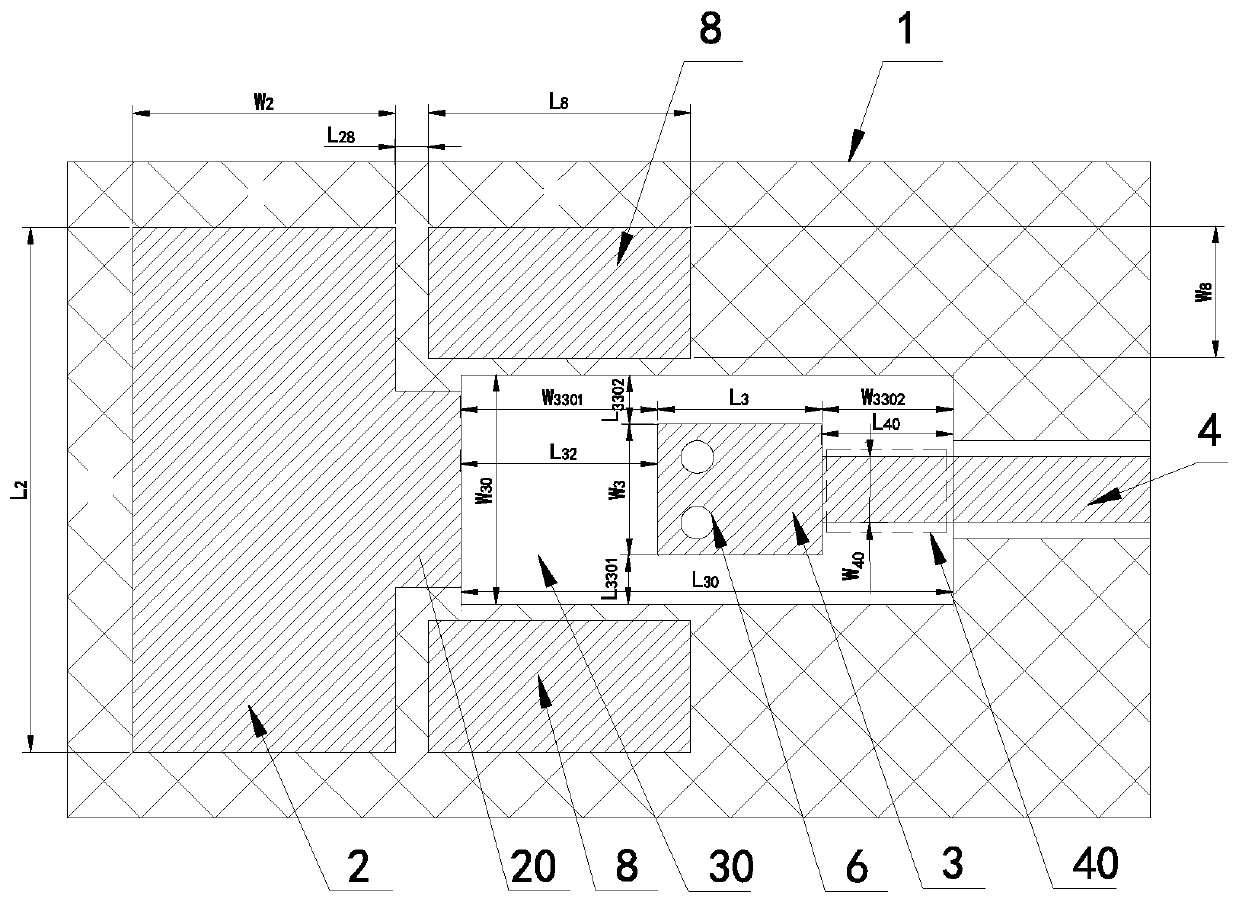

[0056] see Figure 3 to Figure 6 As shown, the first embodiment of the present invention provides a radio frequency interface circuit, which includes a PCB board 1, on the top layer of the PCB board 1, from one end to the other end, there are sequentially provided with a first pad 2, a second pad Disc 3 and transmission line 4, the first pad 2, the second pad 3 are respectively used for dragging the shielding ground net and the core wire of tin welding shielded cable 7, and transmission line 4 usually adopts radio frequency microstrip line; Also set on PCB board 1 There is a first impedance matching network for compensating impedance.

[0057] In the present invention, the top layer and the bottom layer are relative concepts, which refer to the two sides of the PCB board 1. When one of the faces is called the top layer, the other surface oppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com